A kind of water treatment system and method

A technology for a water treatment system and treatment liquid, applied in the field of water treatment, can solve the problems of poor anti-fouling and blocking performance of reverse osmosis membranes, and achieve the effects of avoiding the reduction of the life of the membrane bag, reducing the driving pressure, and improving the anti-fouling blocking performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

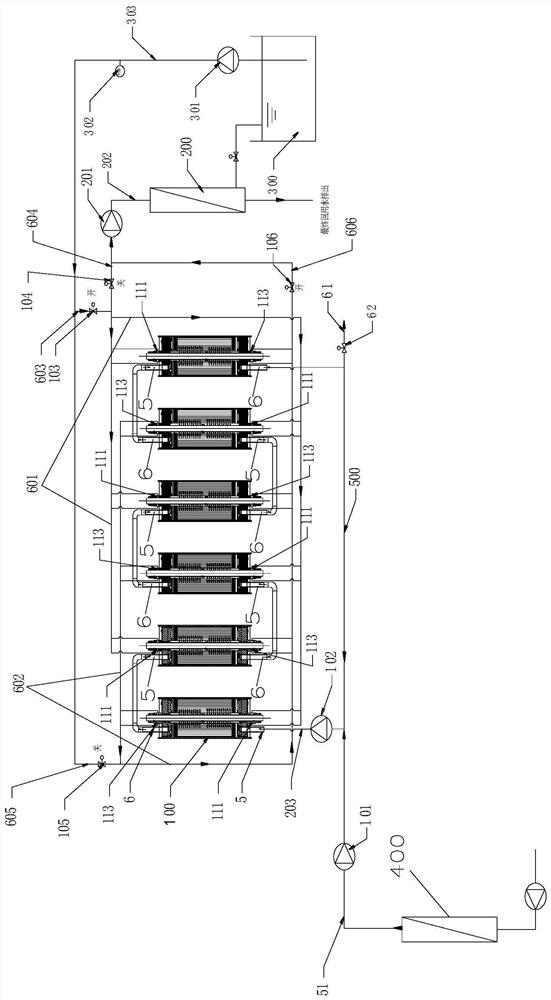

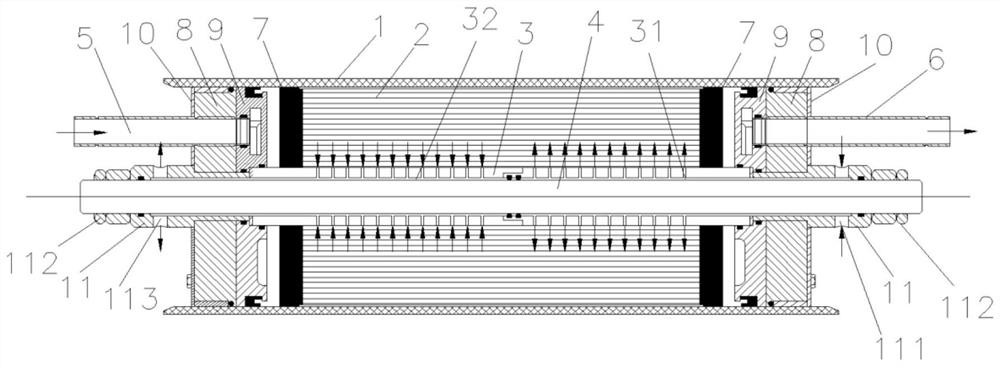

[0073] Such as Figure 1~2 , the first port 111 is located at the same end of the membrane shell 1 as the raw water interface 5 , and the second port 113 is located at the same end of the membrane shell 1 as the concentrated water interface 6 .

[0074] Working principle of switching mechanism:

[0075] Such as figure 1 , open the first valve 103 and the fourth valve 106, close the second valve 104 and the third valve 105, at this time, the first pipeline 601 inputs brine, and the second pipeline 602 outputs the mixed solution; at this time, the first port 111 enters brine, and the second Two ports 113 out of the mixed solution;

[0076] When switching is required, such as figure 2 , open the second valve 104 and the third valve 105, close the first valve 103 and the fourth valve 106, at this time, the second pipeline 602 inputs brine, the first pipeline 601 outputs the mixed solution, at this time, the second port 113 enters brine, the second One mouthful of 111 out of the...

Embodiment 2

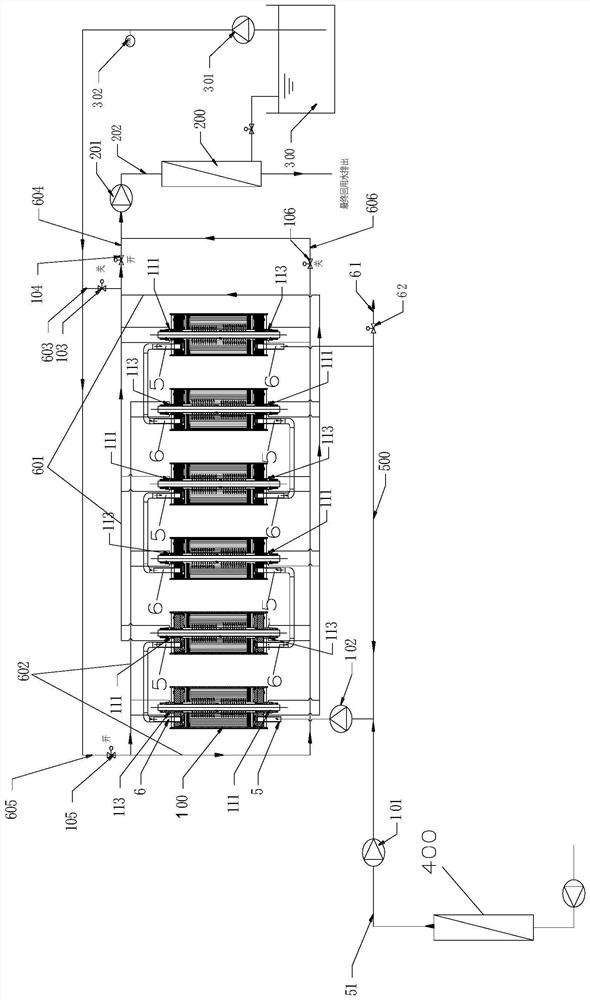

[0078] Such as Figure 7-8 , the first port 111 is set at one end close to the first pipe 601 , and the second port 113 is set at one end close to the second pipe 603 .

[0079] Working principle of switching mechanism:

[0080] Such as Figure 7 , open the first valve 103 and the fourth valve 106, close the second valve 104 and the third valve 105, at this moment, the first pipeline 601 inputs brine, the second pipeline 602 outputs the mixed solution, at this time, the first port 111 enters brine, and the second Two ports 113 out of the mixed solution;

[0081] When switching is required, such as Figure 8 , open the second valve 104 and the third valve 105, close the first valve 103 and the fourth valve 106, at this time, the second pipeline 602 inputs brine, the first pipeline 601 outputs the mixed solution, at this time, the second port 113 enters brine, the second One mouthful of 111 out of the mixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com