Working grounding and safe grounding independent distribution method suitable for high-speed train

A technology for safe grounding and high-speed trains, applied in vehicle components, installations along the running track, transportation and packaging, etc., can solve problems such as damage to connecting equipment, increase in vehicle body voltage, damage to on-board control, communication, etc., to improve safety, The effect of reducing the backflow damage of the track and avoiding the interference of the car body circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

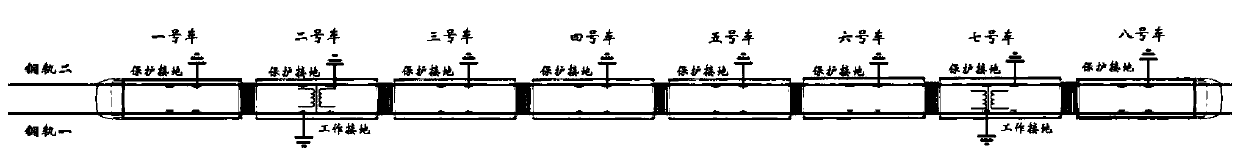

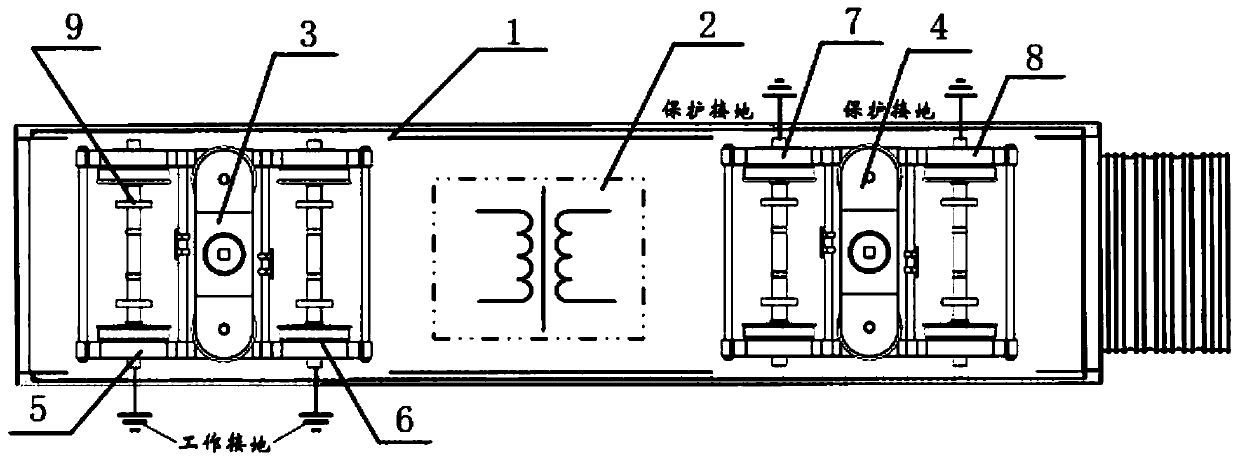

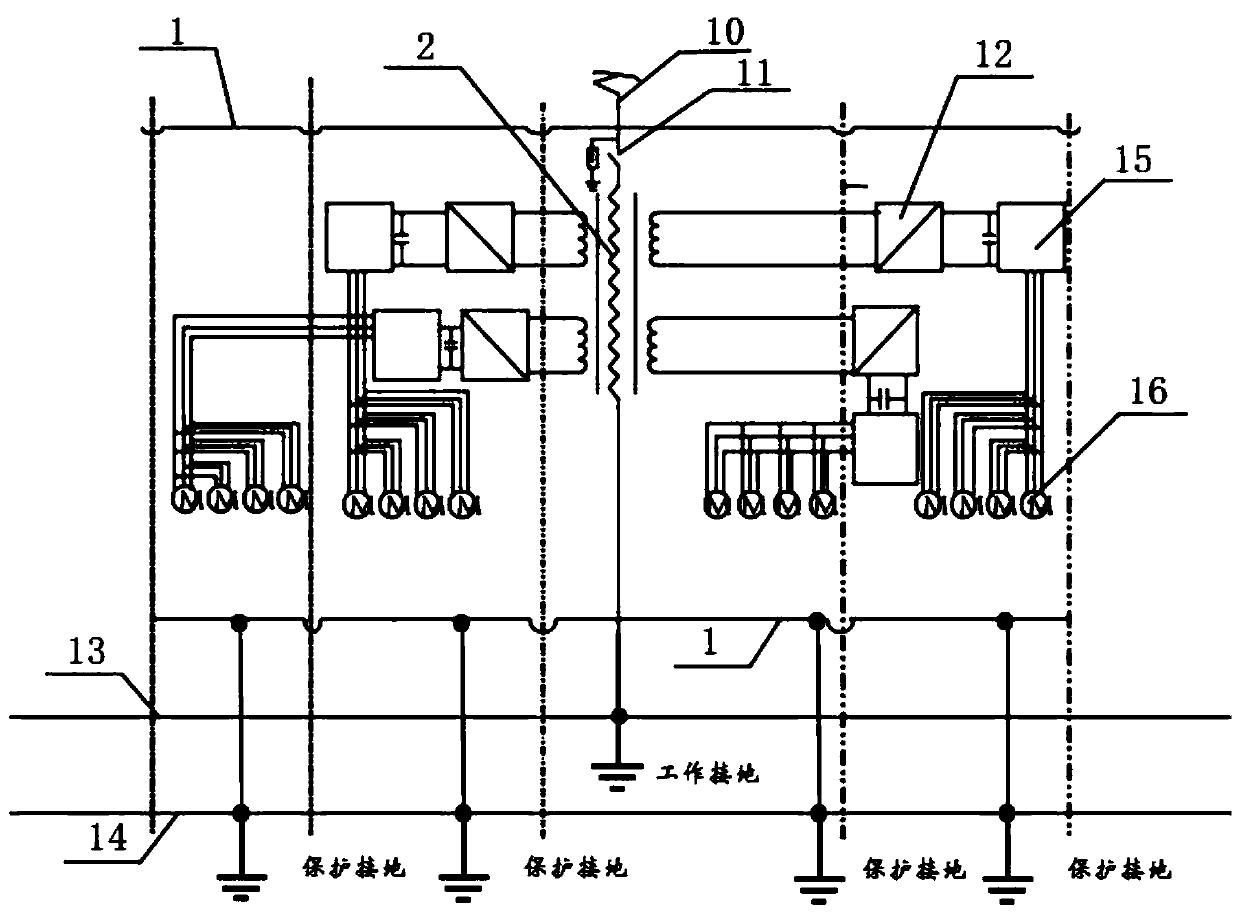

[0024] A method for independent distribution of work and safety grounding suitable for high-speed trains of the present invention, the distribution method is as follows figure 1 As shown, the working grounding system and the safety grounding system are independently distributed on the sides of the two rails. The working grounding system is distributed in the traction compartment; the safety grounding system is distributed in each compartment.

[0025] Among them, the grounding process of the working grounding system is as follows: the compartment 1 receives 25KV / 50HZ high-voltage AC power from the catenary through the pantograph 10, transmits it to the primary side of the transformer 2 through the vacuum circuit breaker 11, and then slides through the grounding carbon brush 18 to the Wheel one 5 and wheel two 6 are in rolling contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com