A release mechanism for an engine baffle

A release mechanism and baffle technology, applied in the direction of machine/engine, rocket engine device, mechanical equipment, etc., can solve the problems of flight failure, escape failure, hitting the arrow body, etc., to achieve accurate and rapid control effect, stable and reliable connection , lock and release process is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the accompanying drawings and examples.

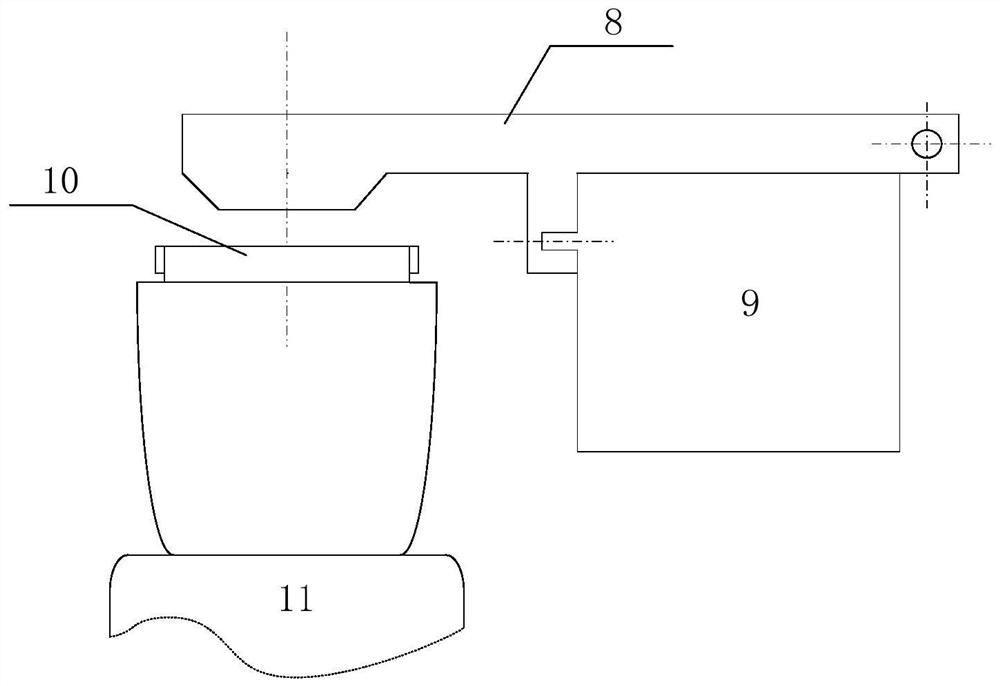

[0017] Such as figure 1 As shown, it is a schematic diagram of the installation position of the engine variable thrust baffle and the release mechanism. The rear part of the baffle 8 is installed by a rotating shaft and can be turned over; the front end is located at the nozzle of the nozzle 10 of the engine 11; the release mechanism 9 of the present invention is installed The middle part of the baffle 8 can realize locking and release of the baffle 8 .

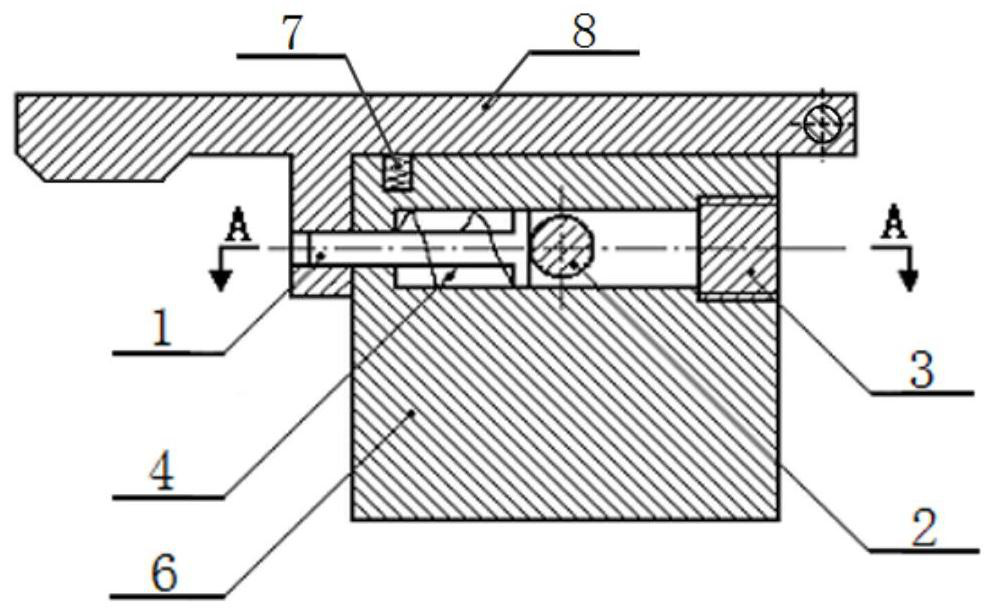

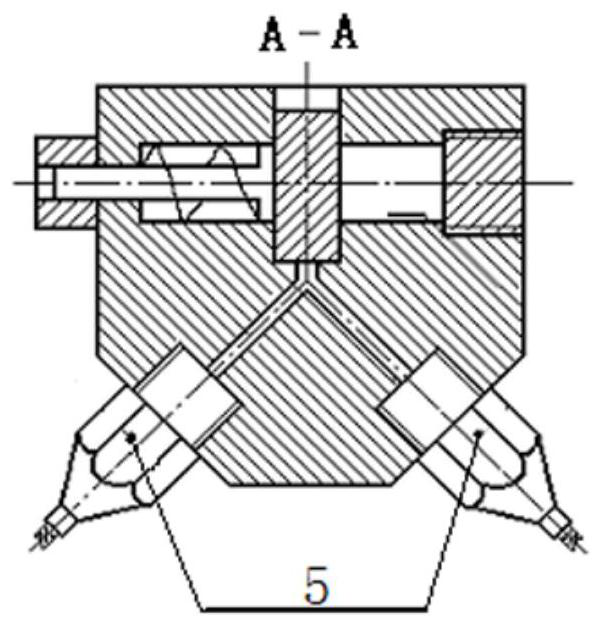

[0018] As shown in 2(a) and 2(b), the release mechanism 9 of the present invention includes a locking pin 1, a release pin 2, a screw 3, a pin spring 4, an electric squib 5, a support 6 and a release spring 7.

[0019] The support 6 is installed close to the lower surface of the baffle 8, and there are two inner passages perpendicular to each other inside the support 6: the first passage in the shape of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com