A precision pointing platform based on flexible parallelogram mechanism

A parallelogram and flexible technology, applied in the direction of machine/support, supporting machine, mechanical equipment, etc., can solve the problems of output platform rotation center drift, driver harmful lateral motion isolation, axial and lateral parasitic motion, etc. Achieve the effect of avoiding temperature drift error, reducing adverse effects, and reducing lateral displacement transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

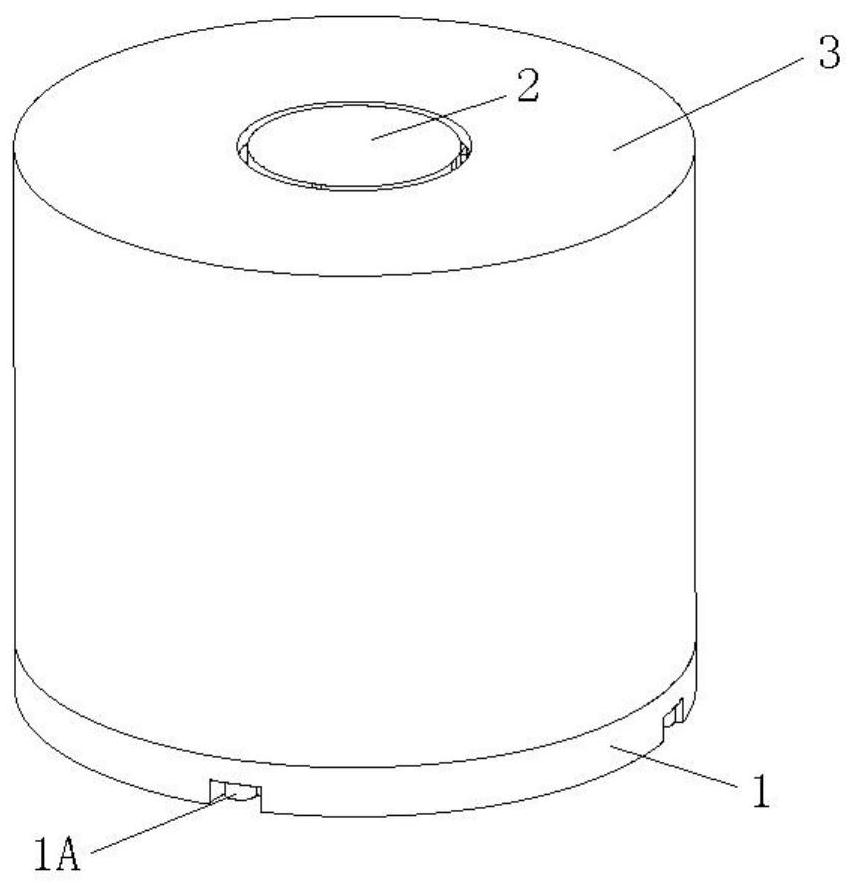

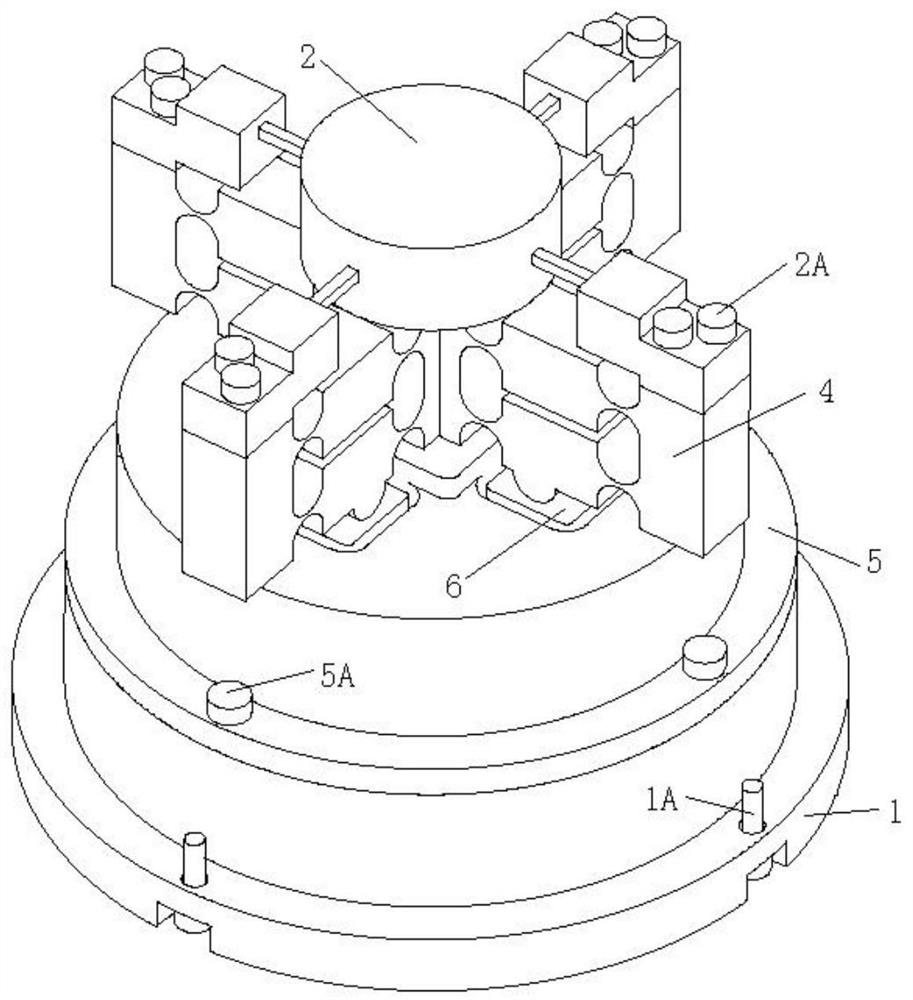

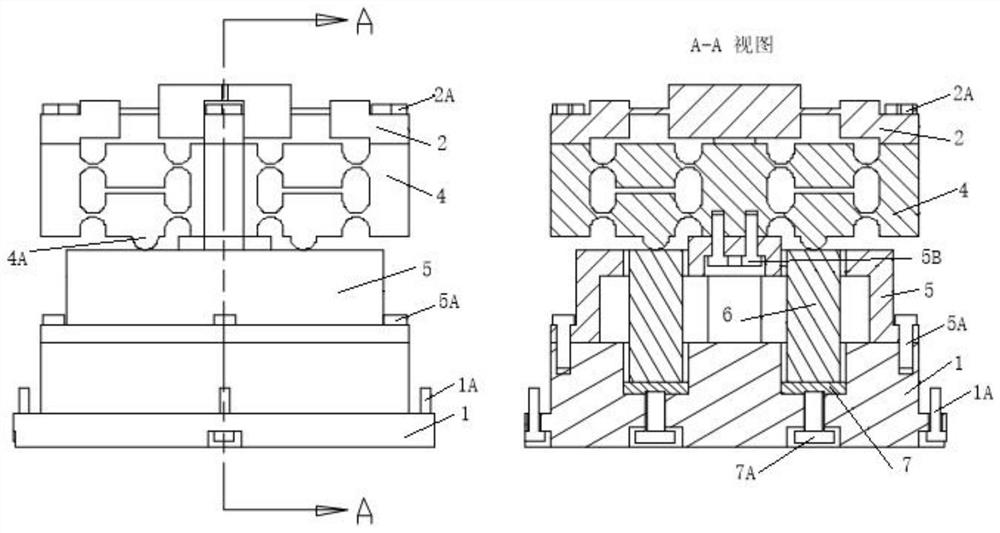

[0045] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

[0046] The object of the present invention is to provide a precision pointing platform device based on a flexible parallelogram mechanism. The precise pointing platform device can complete the two-dimensional deflection function in space. The invention adopts a piezoelectric ceramic driver as a driving input, and realizes pointing motion guidance by constructing a flexible parallelogram rotating guide mechanism. The four parallelogram branch chains of the pointing platform are distributed symmetrically at 90°, forming a four-point parallel drive configuration, which can effectively reduce prelo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com