Efficient combustor

A kind of burner, high-efficiency technology, applied in the direction of burner, gas fuel burner, combustion method, etc., can solve the problems of insufficient high-efficiency combustion, limited secondary air supply capacity, etc., to shorten the supply path, improve supply efficiency, and improve The effect of combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

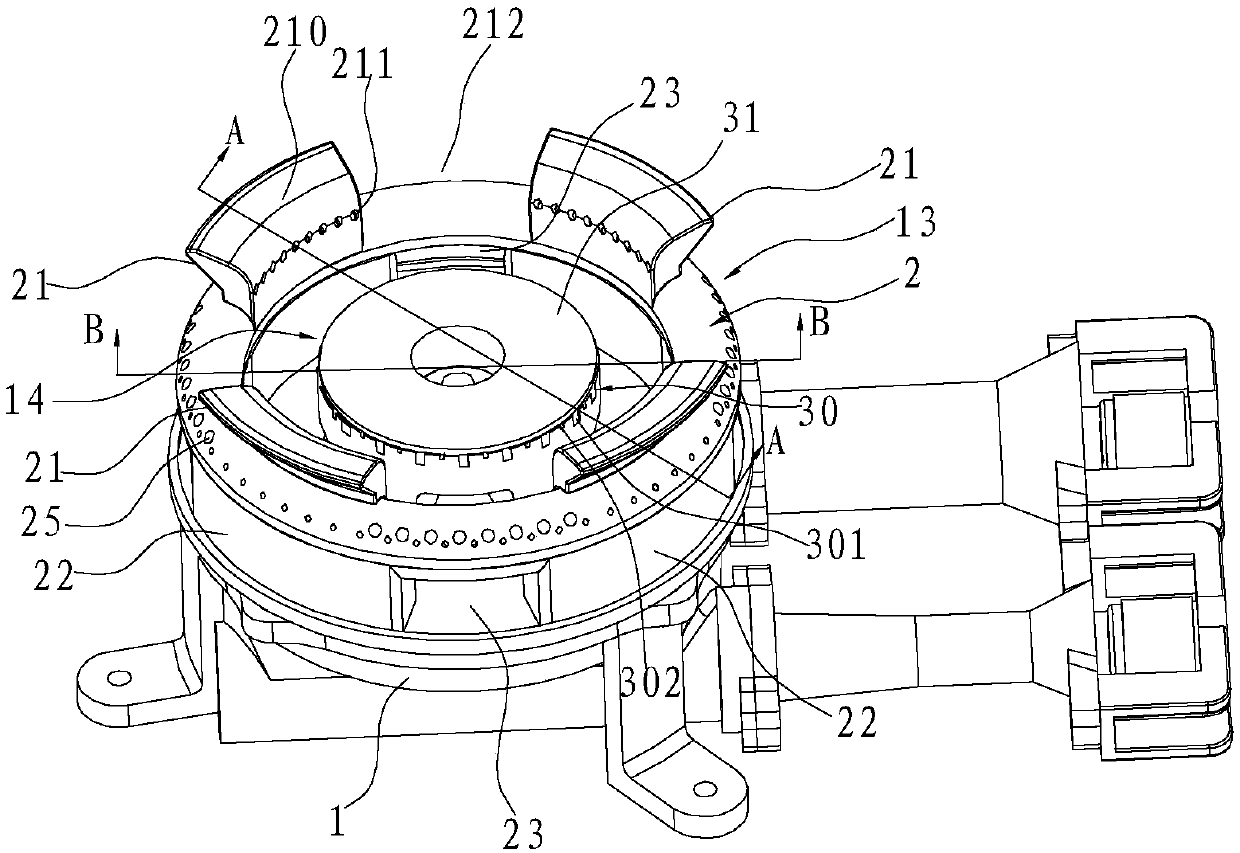

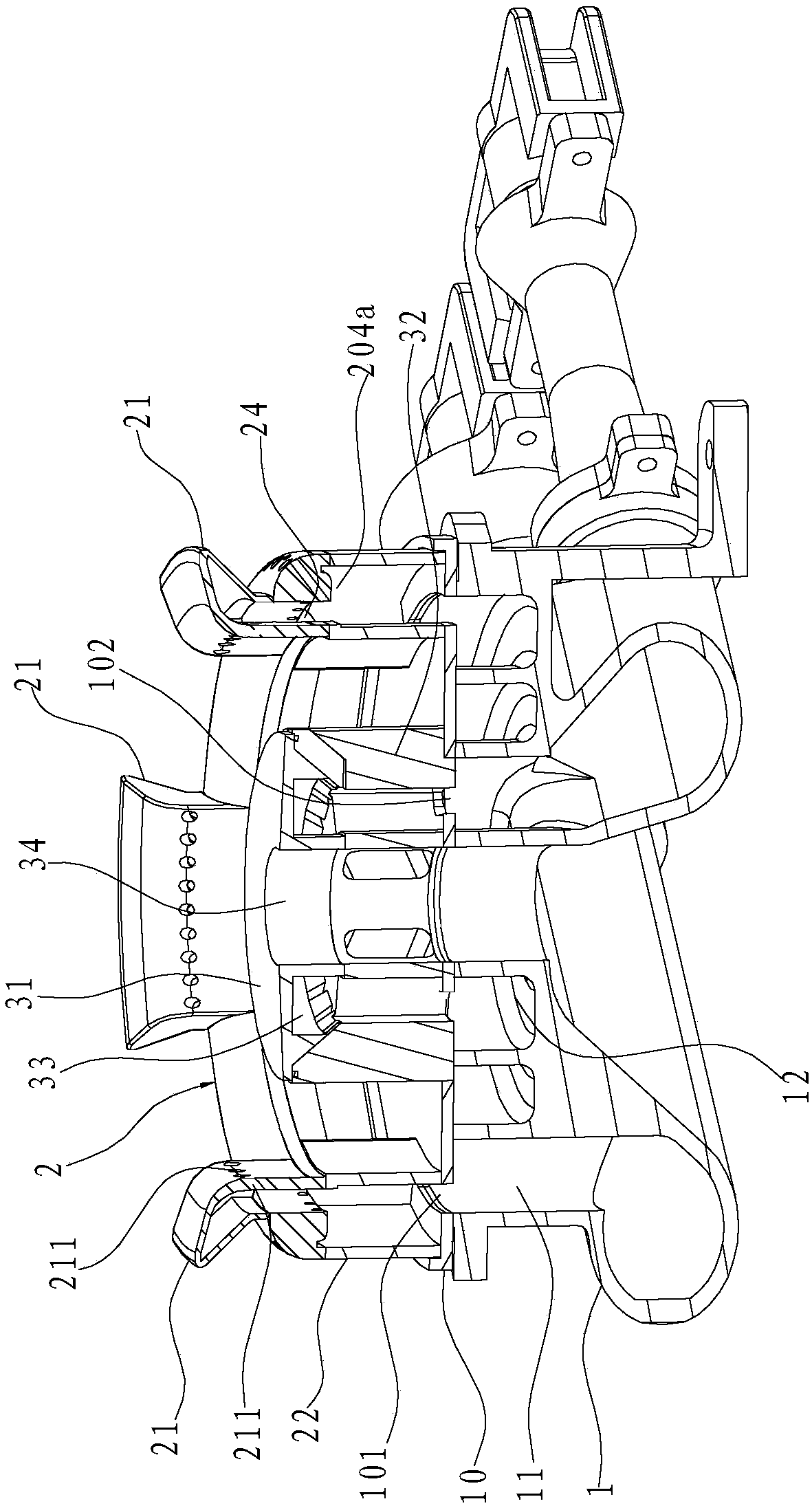

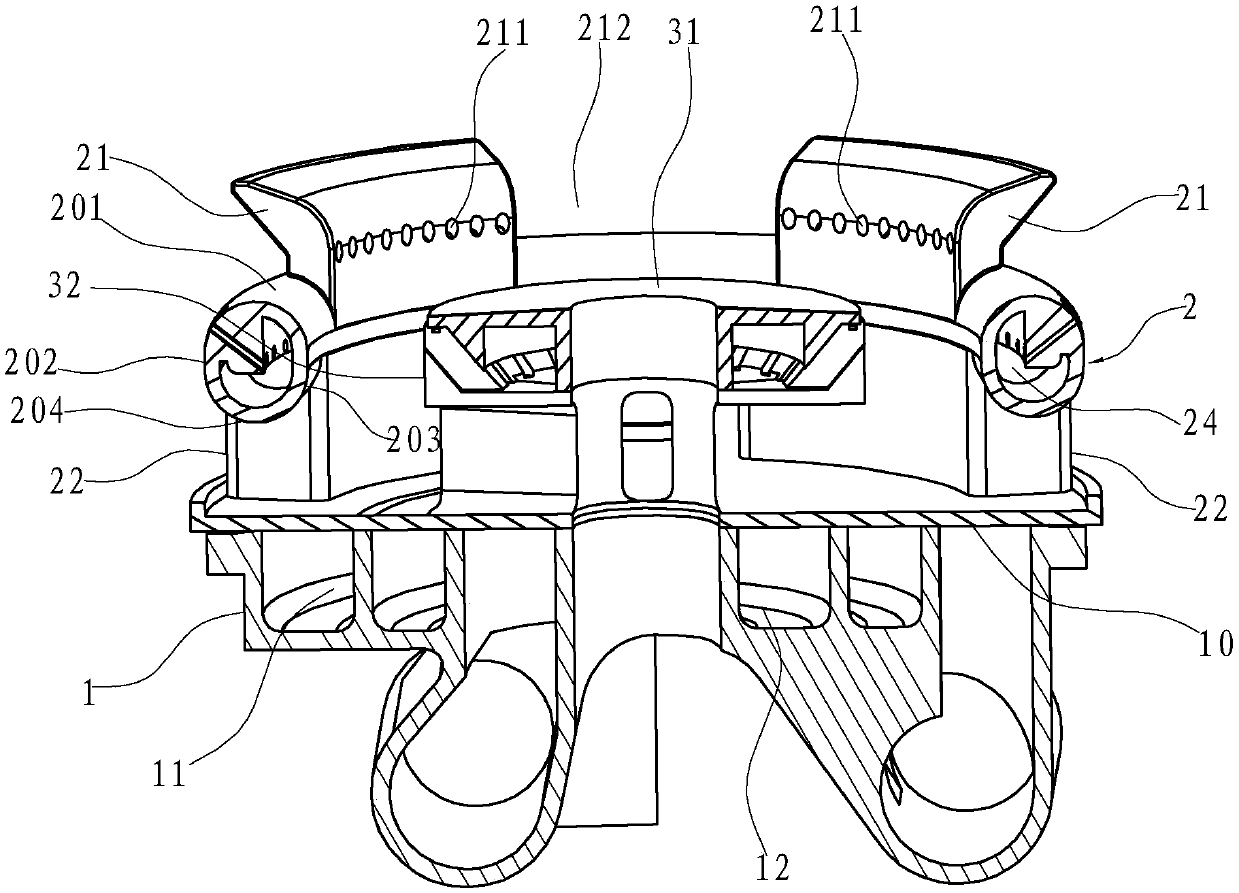

[0026] Such as Figure 1~6 As shown, a high-efficiency burner includes a base 1 and an outer ring fire cover 13 and an inner ring fire cover 14 arranged on the base 1 . Wherein the outer ring fire cover 13 comprises a ring-shaped outer ring fire cover body 2, and the outer ring fire cover body 2 includes an annular top surface 201 and the inner edge and the outer edge of the annular top surface 201 are vertically or obliquely downward. The extended inner ring wall 203 and the outer ring wall 202, the outer ring air mixing chamber 24 is formed between the above-mentioned annular top surface 201, the inner ring wall 203 and the outer ring wall 202, and the outer ring wall 202 is arranged at intervals along the circumferential direction Main fire hole 25 is arranged.

[0027] Further, the outer ring fire cover body 2 includes a first part 20a and a second part 20b, the first part 20a and the second part 20b are arranged at intervals along the circumference of the outer ring fire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com