Fire cover and high-efficiency burner applying fire cover

A gas burner and fire cover technology, which is applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of insufficient high-efficiency combustion, limited secondary air supply capacity, etc., to shorten the supply path and improve supply efficiency , the effect of improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

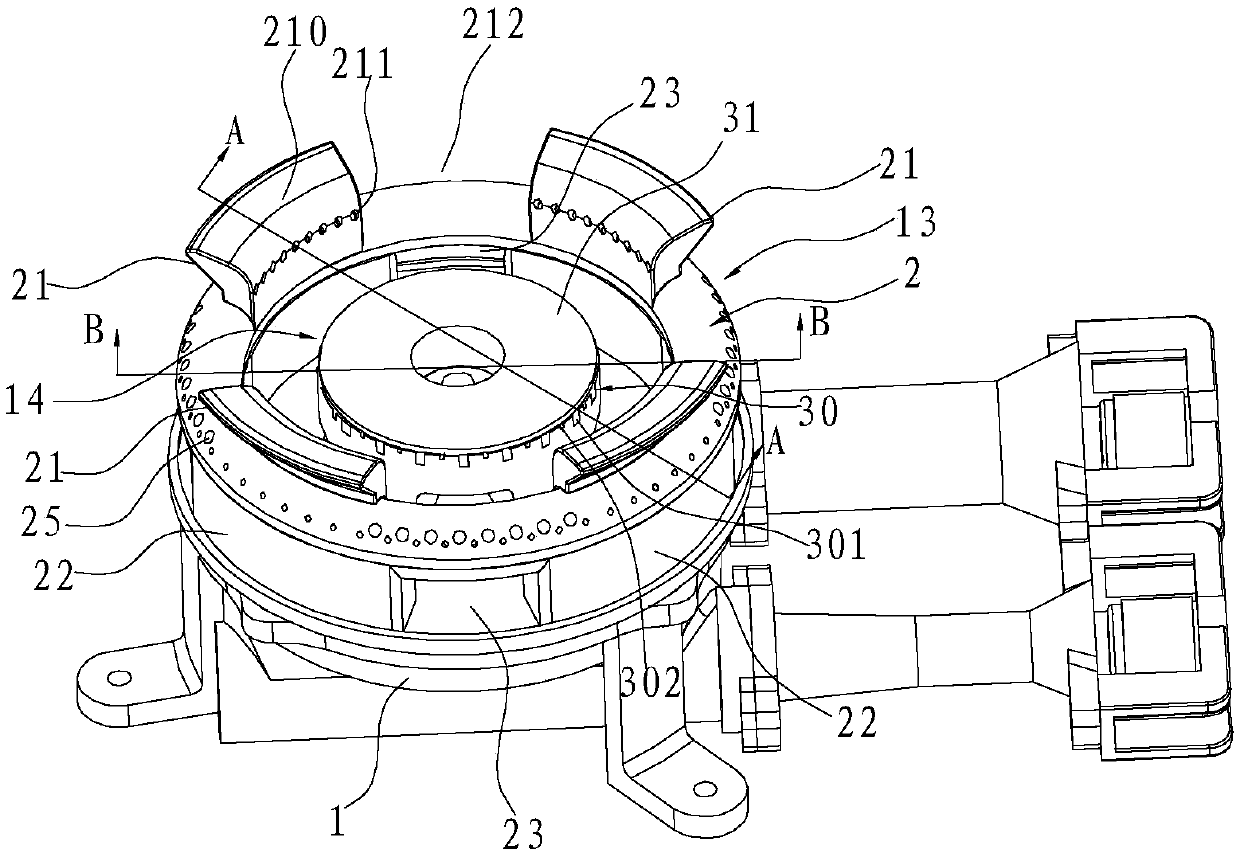

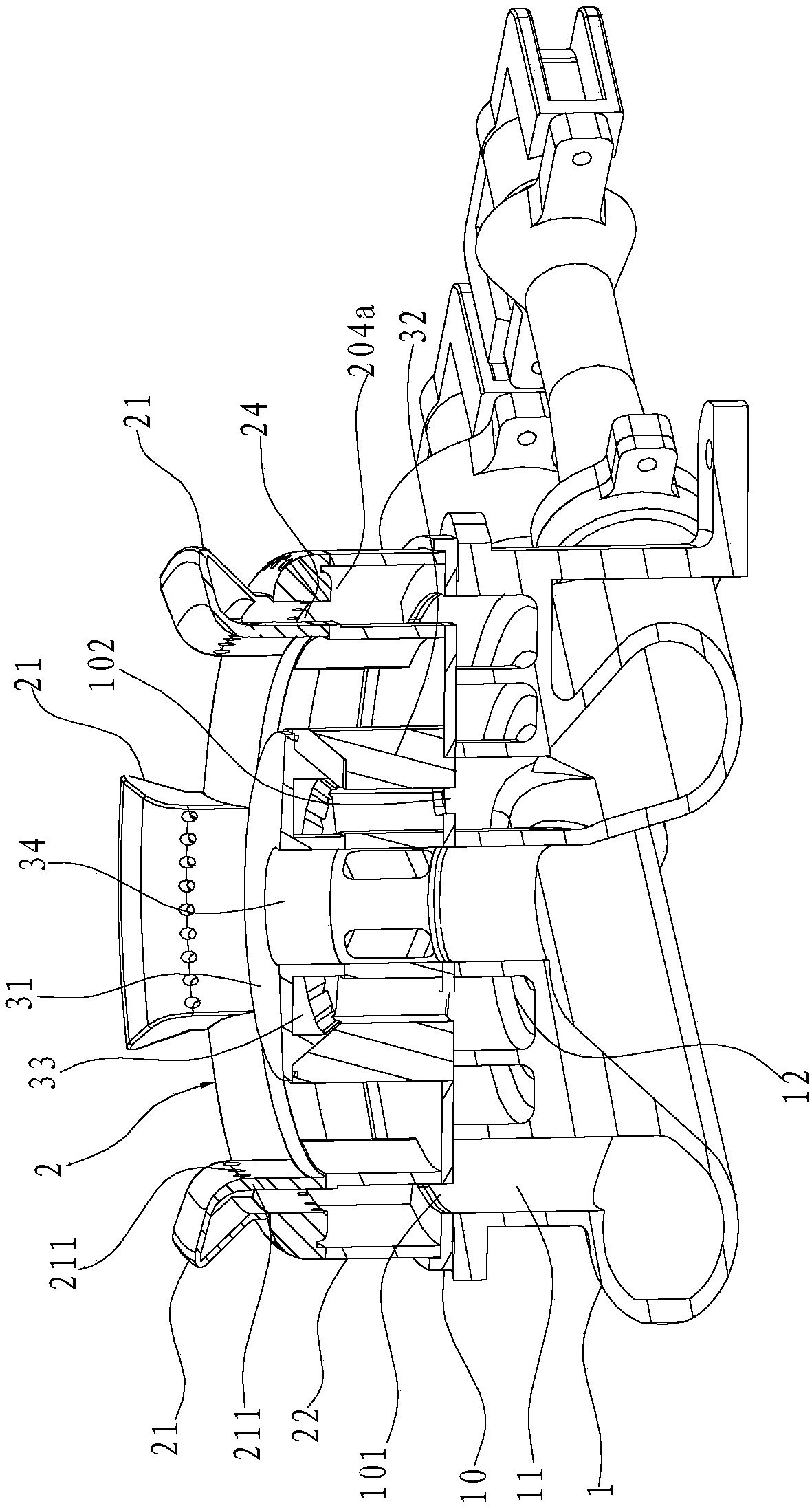

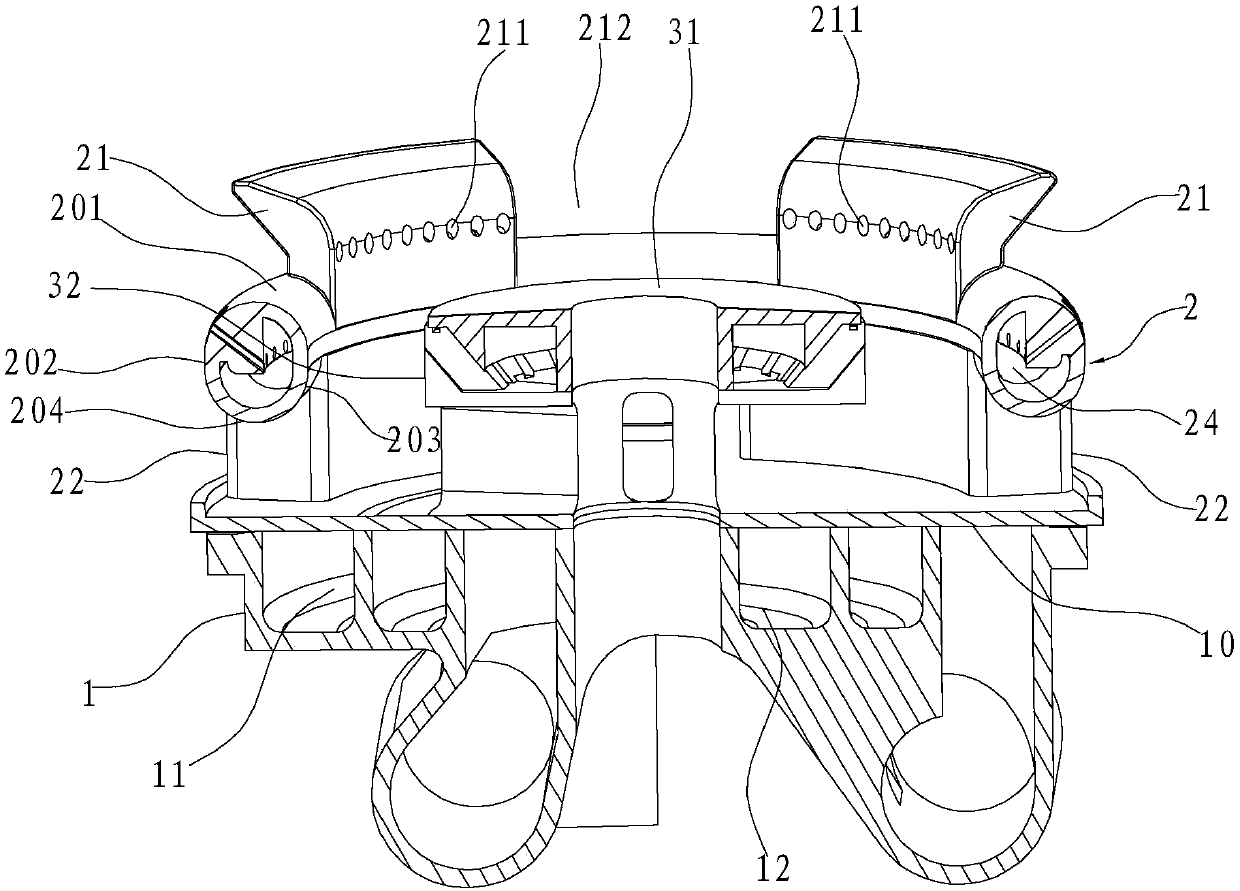

[0029] Such as Figure 1~6 As shown, a high-efficiency burner includes a base 1 and an outer ring fire cover 13 and an inner ring fire cover 14 arranged on the base 1 . Wherein the outer ring fire cover 13 comprises a ring-shaped first fire cover body 2, the first fire cover body 2 includes an annular top surface 201 and the inner edge and the outer edge of the annular top surface 201 are vertical or inclined downward. The extended inner ring wall 203 and the outer ring wall 202, the first air mixing chamber 24 is formed between the above-mentioned annular top surface 201, the inner ring wall 203 and the outer ring wall 202, and the above-mentioned outer ring wall 202 is arranged at intervals along the circumferential direction Main fire hole 25 is arranged.

[0030] Further, the lower edge of the outer ring wall 202 and the inner ring wall 203 are connected by the lower ring wall 204, and the lower ring wall 204 is provided with a plurality of air inlets 204a at intervals in...

Embodiment 2

[0039] Such as Figure 6 and 8 As shown, the difference from Embodiment 1 is that the inner ring fire cover 14 in this embodiment adopts a different structure from Embodiment 1. Specifically, the structure of the inner ring fire cover 14 in this embodiment is the same as that of the outer ring fire cover 13 in the first embodiment. In this way, the number of the inner ring vents 102 matches the number of the above-mentioned gas mixing tubes 22, and the free ends of each gas mixing tubes 22 are respectively connected to the corresponding inner ring vents 102, so that the outer ring cavity 11 passes through each The outer ring air vent 101 communicates with each gas mixing pipe 22 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com