Fluid filled tactile sensor

A tactile sensor and asana technology, applied in instruments, measuring devices, etc., can solve problems such as noise, temperature change sensitivity, and inability to detect slippery feeling, etc., to achieve increased accuracy and stability, stable performance, and strong environmental robustness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] The present invention will be further described through specific examples below, but it is not intended to limit the present invention. Any modifications, equivalent replacements, improvements, etc. made within the implementation methods and principles of the present invention should be included in the protection scope of the present invention. Inside.

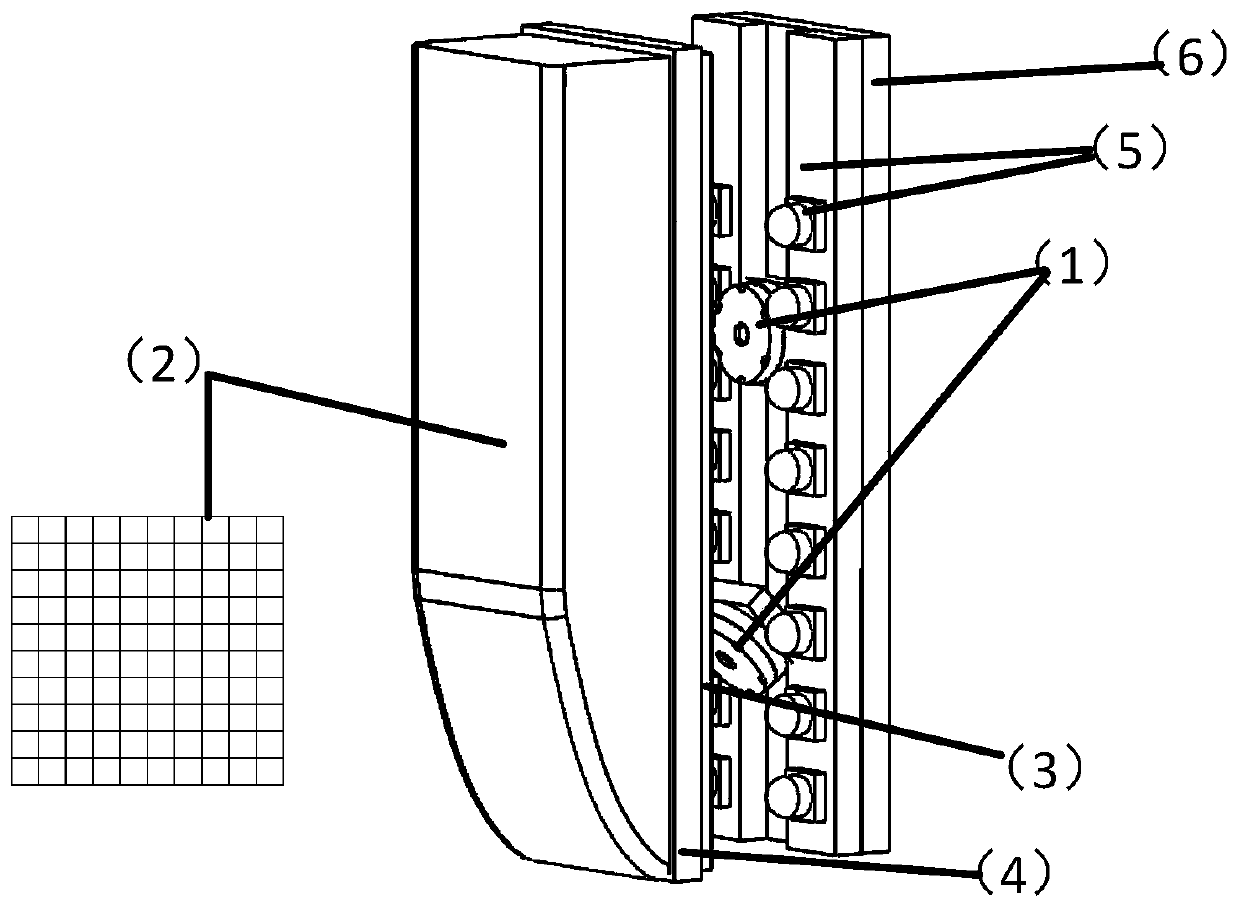

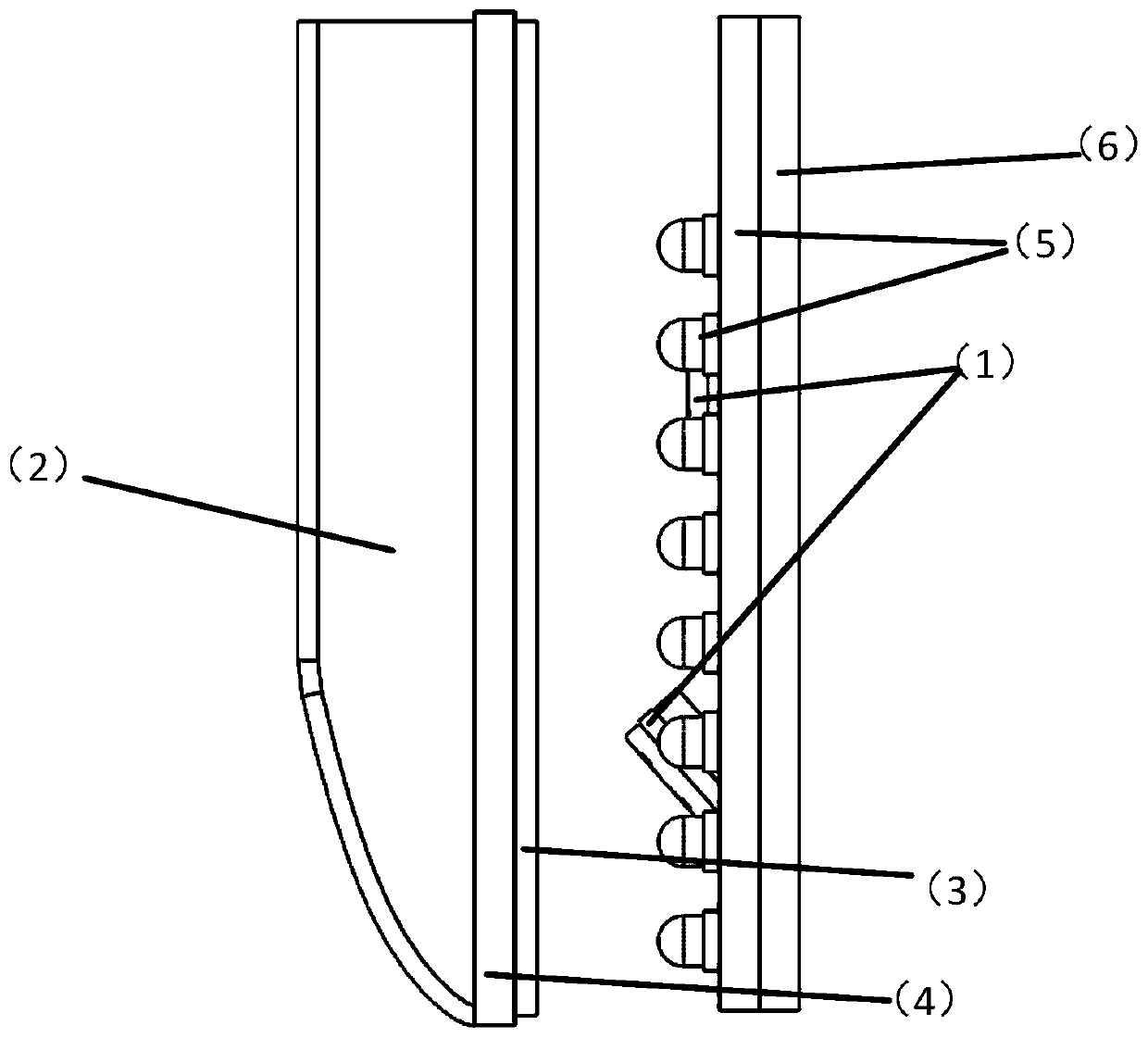

[0017] See figure 1 and figure 2 As shown, a fluid-filled tactile sensor includes a camera 1, an elastic rubber 2, a glass sheet 3, a circuit board 5 provided with a light source, and a housing 6; the elastic rubber 2 and the glass sheet 3 are connected by a sealing ring 4 , forming a sealed cavity between the elastic rubber 2 and the glass sheet, the cavity is filled with fluid, which can increase the recovery ability of the elastic rubber 2, the fluid is liquid or gas, gas is preferred, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com