Slow tensile testing device for R6 grade mooring chain under cathodic protection

A cathodic protection and tensile test technology, which is applied in the field of mooring chains, can solve the problems of harsh corrosive environments and the difficulty of comprehensively investigating the performance of environmental embrittlement resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the purpose of the invention, technical solutions and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods;

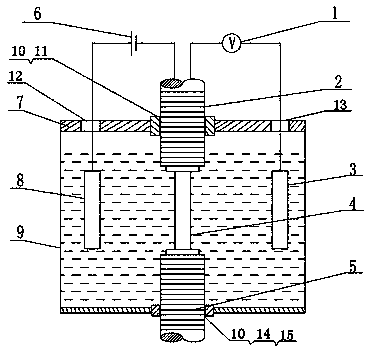

[0014] In the accompanying drawings: a slow tensile test device under R6 mooring chain cathodic protection, which is characterized in that it includes a barrel-shaped container 9 filled with artificial seawater, an upper tensile clamp 2, and a lower tensile clamp 5; The above-mentioned barrel-shaped container 9 is opened upwards, and a cover plate 7 is arranged at the opening position; the center position of the cover plate 7 is provided with a through hole a11 for placing the upper stretching fixture 2, and the left side of the through hole a11 is provided with an installation auxiliary The through hole b12 of the anode 8, the right side of the through hole a11 is provided with the through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com