Point grinding polisher of glass panels

A glass panel and polishing machine technology, applied in the field of polishing machines, can solve problems such as high labor intensity, inability to polish glass panels, unfavorable intelligent automation of factory production, etc., and achieve the effect of ensuring operation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

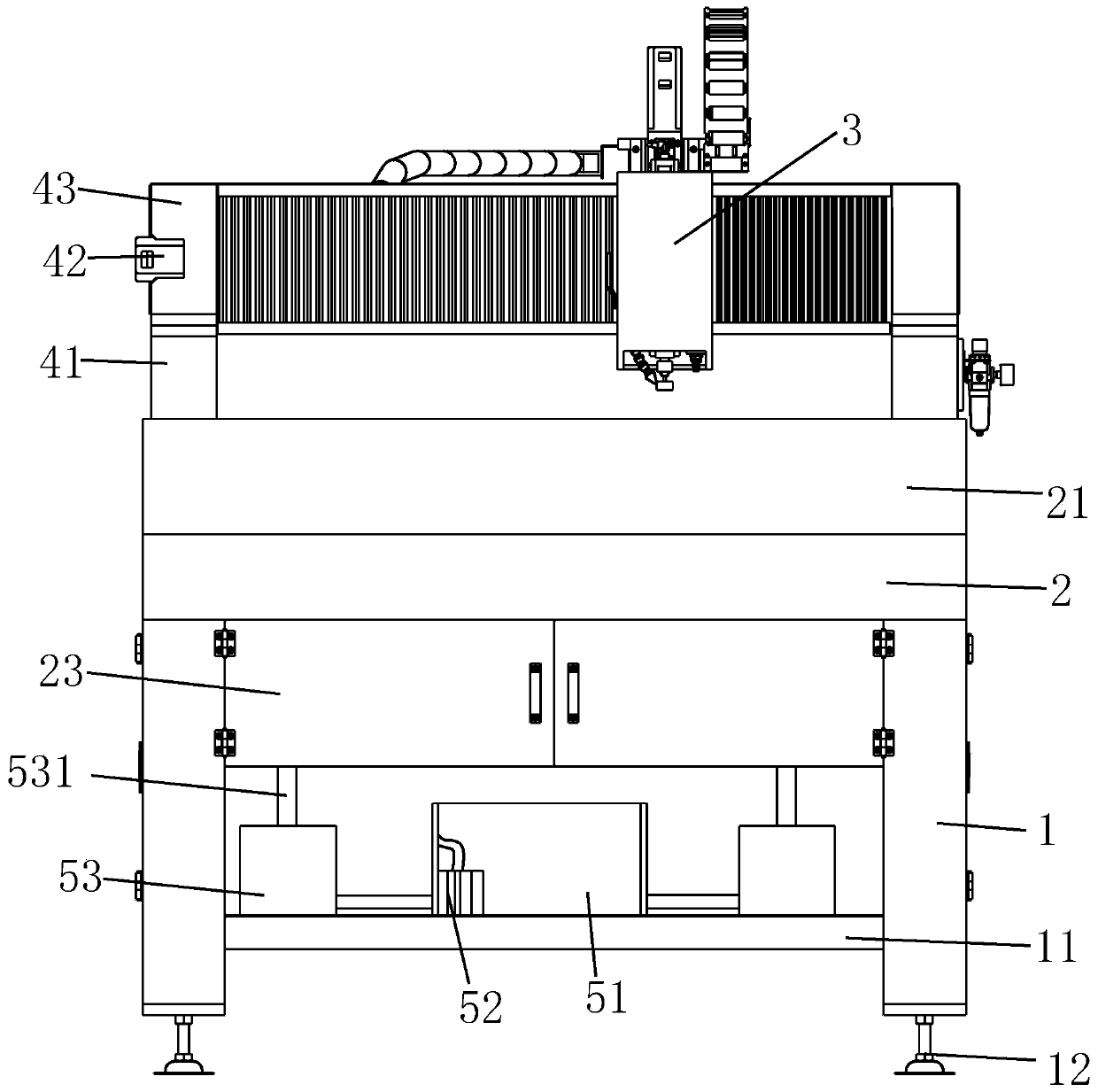

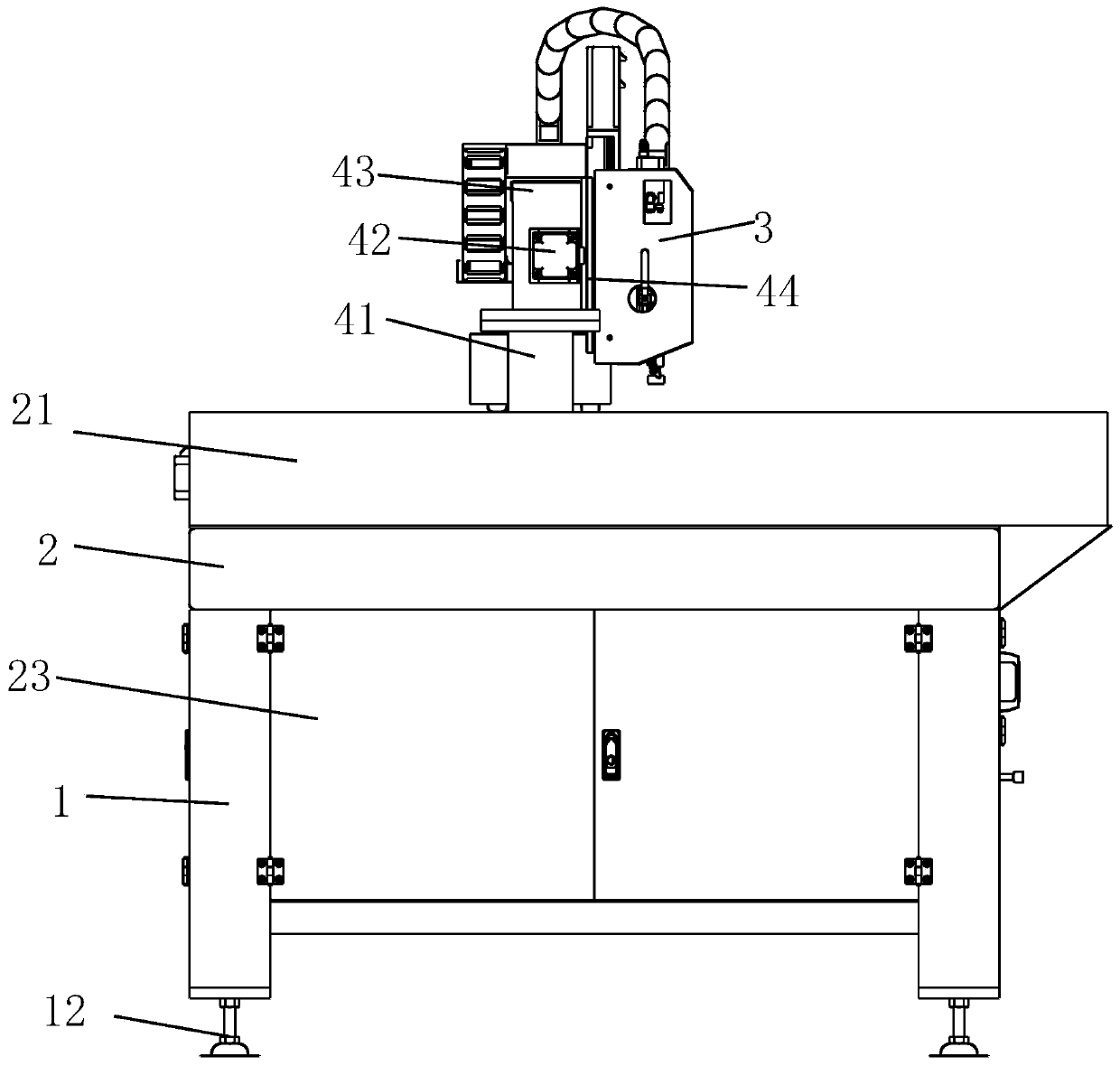

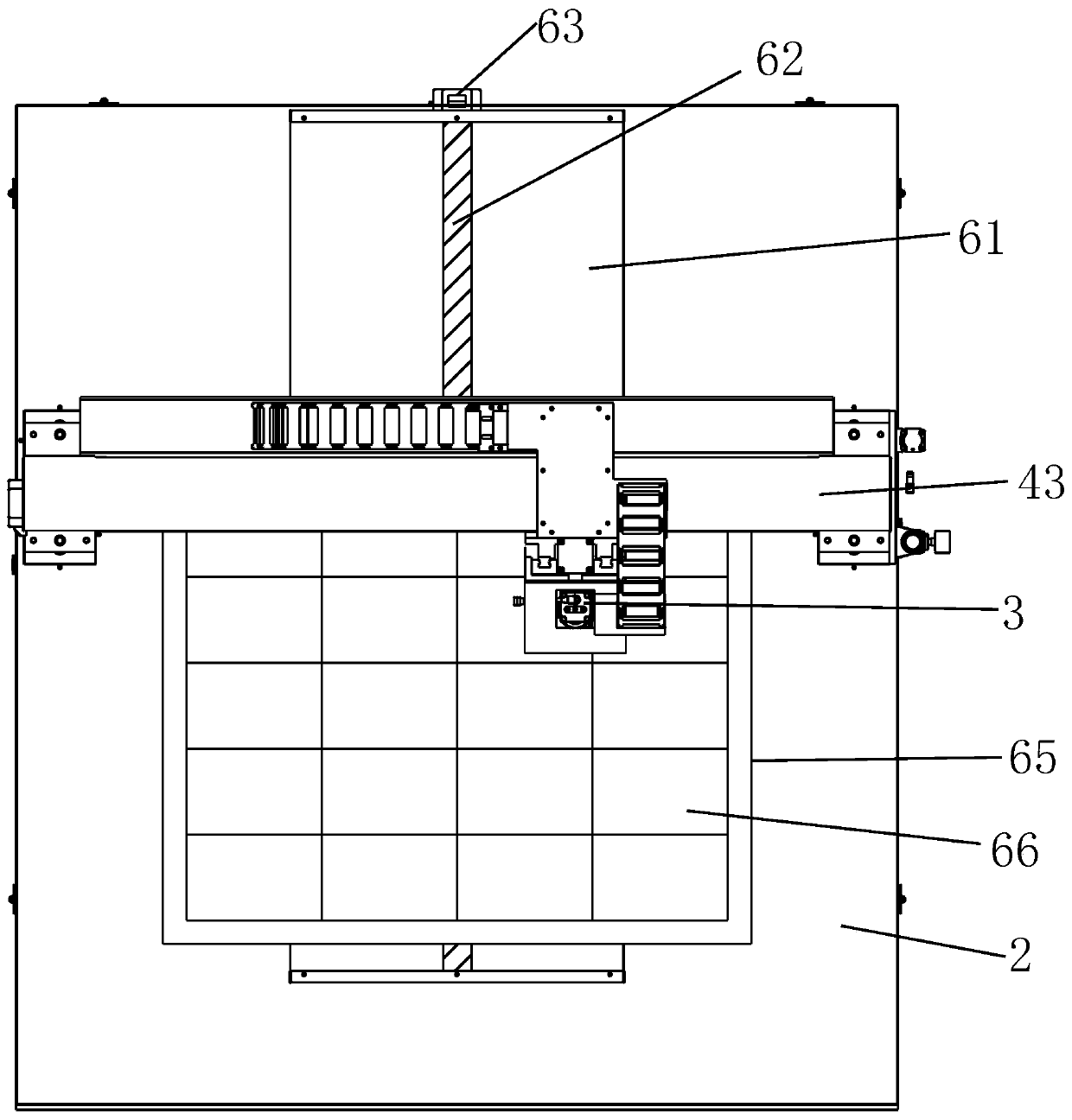

[0031] Such as Figure 1-Figure 10 As shown, a glass panel point grinding and polishing machine, including:

[0032] The base 2 is provided with support columns 1 at the four corners of the bottom of the base 2, and side plates 21 are provided on the sides of the upper surface of the base 2;

[0033] A lateral movement mechanism, the lateral movement mechanism is horizontally arranged in the middle of the base 2, and a grinding device is arranged on the lateral motor mechanism;

[0034] The longitudinal movement mechanism is longitudinally arranged in the middle of the base 2, and the longitudinal movement mechanism is provided with a bearing platform 65, and a glass panel 66 is uniformly placed in the bearing platform 65.

[0035] The lateral movement mechanism comprises a column 41 relatively arranged on the base 2, the top of the column 41 is fixedly provided with a crossbeam 43, the middle part of the crossbeam 43 has a moving groove 431, and one end of the crossbeam 43 i...

Embodiment 2

[0039] Such as Figure 1-Figure 10 As shown, a glass panel point grinding and polishing machine, including:

[0040] The base 2 is provided with support columns 1 at the four corners of the bottom of the base 2, and side plates 21 are provided on the sides of the upper surface of the base 2;

[0041] A lateral movement mechanism, the lateral movement mechanism is horizontally arranged in the middle of the base 2, and a grinding device is arranged on the lateral motor mechanism;

[0042] The longitudinal movement mechanism is longitudinally arranged in the middle of the base 2, and the longitudinal movement mechanism is provided with a bearing platform 65, and a glass panel 66 is uniformly placed in the bearing platform 65.

[0043]The lateral movement mechanism comprises a column 41 relatively arranged on the base 2, the top of the column 41 is fixedly provided with a crossbeam 43, the middle part of the crossbeam 43 has a moving groove 431, and one end of the crossbeam 43 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com