A Vacuum Filling Control Method of Workpiece Based on Abnormality Detection

A control method and vacuum perfusion technology, applied in vacuum gauges, packaging automatic control, measuring devices, etc., can solve the problems of perfusion gas waste, wear of perfusion pipeline connectors, and inability to carry out maintenance work in time, so as to reduce waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, wherein the schematic embodiments and descriptions are only used to explain the present invention, but are not intended to limit the present invention.

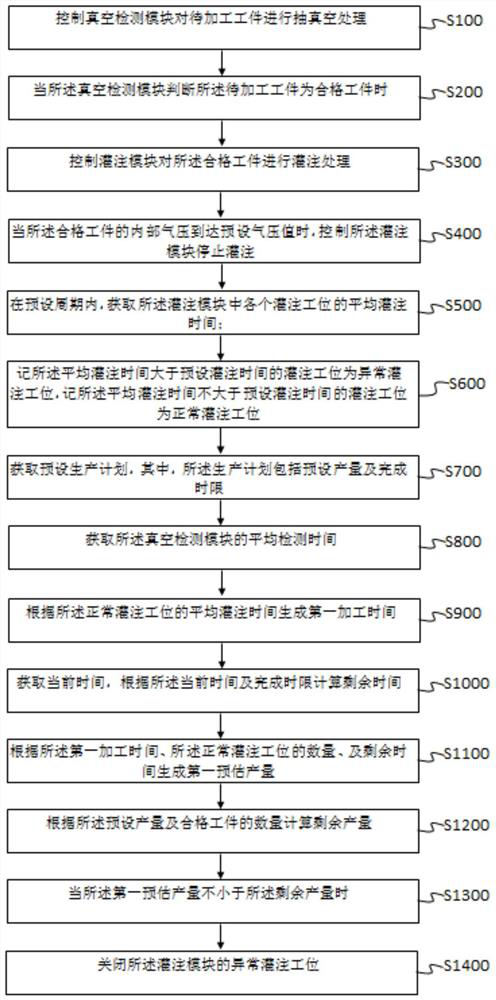

[0072] The present invention provides a workpiece vacuum perfusion control method based on abnormal detection. In an embodiment of the present invention, such as figure 1 shown, including:

[0073] S100: Control the vacuum detection module to vacuumize the workpiece to be processed;

[0074] S200: when the vacuum detection module determines that the workpiece to be processed is a qualified workpiece;

[0075] S300: Control the perfusion module to perfuse the qualified workpiece;

[0076] S400: when the internal air pressure of the qualified workpiece reaches a preset air pressure value, control the perfusion module to stop perfusion;

[0077] S500: within a preset period, obtain the average per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com