A kind of high-gloss environmental protection paint for wood and preparation method thereof

An environmental protection and woodware technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of limited coating system formulation and coating process, low film fullness, immature water-based polyurethane curing process, etc. Better layer protection and appearance, improved film hardness, improved film fullness and gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

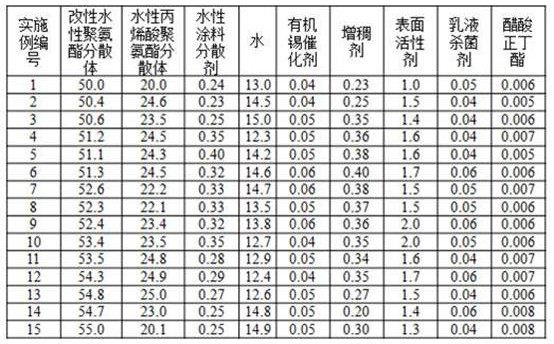

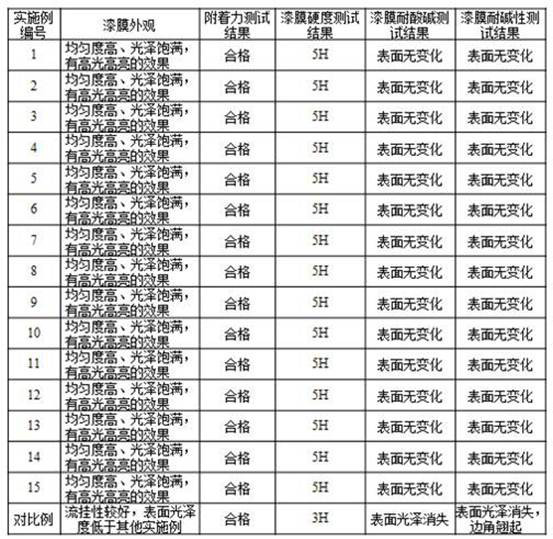

Examples

Embodiment Construction

[0037] The present invention will be described in detail below with reference to the embodiments.

[0038] 1. Preparation of modified waterborne polyurethane dispersion

[0039] Confirm the most suitable ratio of reactant addition through multiple tests. The steps of test ① are as follows:

[0040] S01: Mix the polyether polyol N210, epoxy resin E51 and linseed oil in a mass ratio of 1.52:1:0.24, then dry and dehydrate for 4 hours at 145° C. and 100-120Pa vacuum.

[0041] S02: Mix the mixture in S01 with isophorone diisocyanate in a mass ratio of 1.3:1, and stir and react under nitrogen atmosphere for 3.4 hours.

[0042] S03: Add 1,4-butanediol to the reactant in S02 and react for 2h, then add trimethylolpropane to react at 82-85°C for 3.5h, then cool down to 60°C, then add 2,2- Dimethylolpropionic acid and N-methylpyrrolidone were reacted for 3h, and then cooled to room temperature naturally to obtain a modified aqueous polyurethane prepolymer; reactants, 1,4-butanediol, tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com