A rib of knitted one-piece shoe and its knitting process

A one-piece, cuff technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve problems such as poor elasticity of the cuff, failure to reach customers, poor shaping, etc., to achieve good shaping, easy pulling, and high elasticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

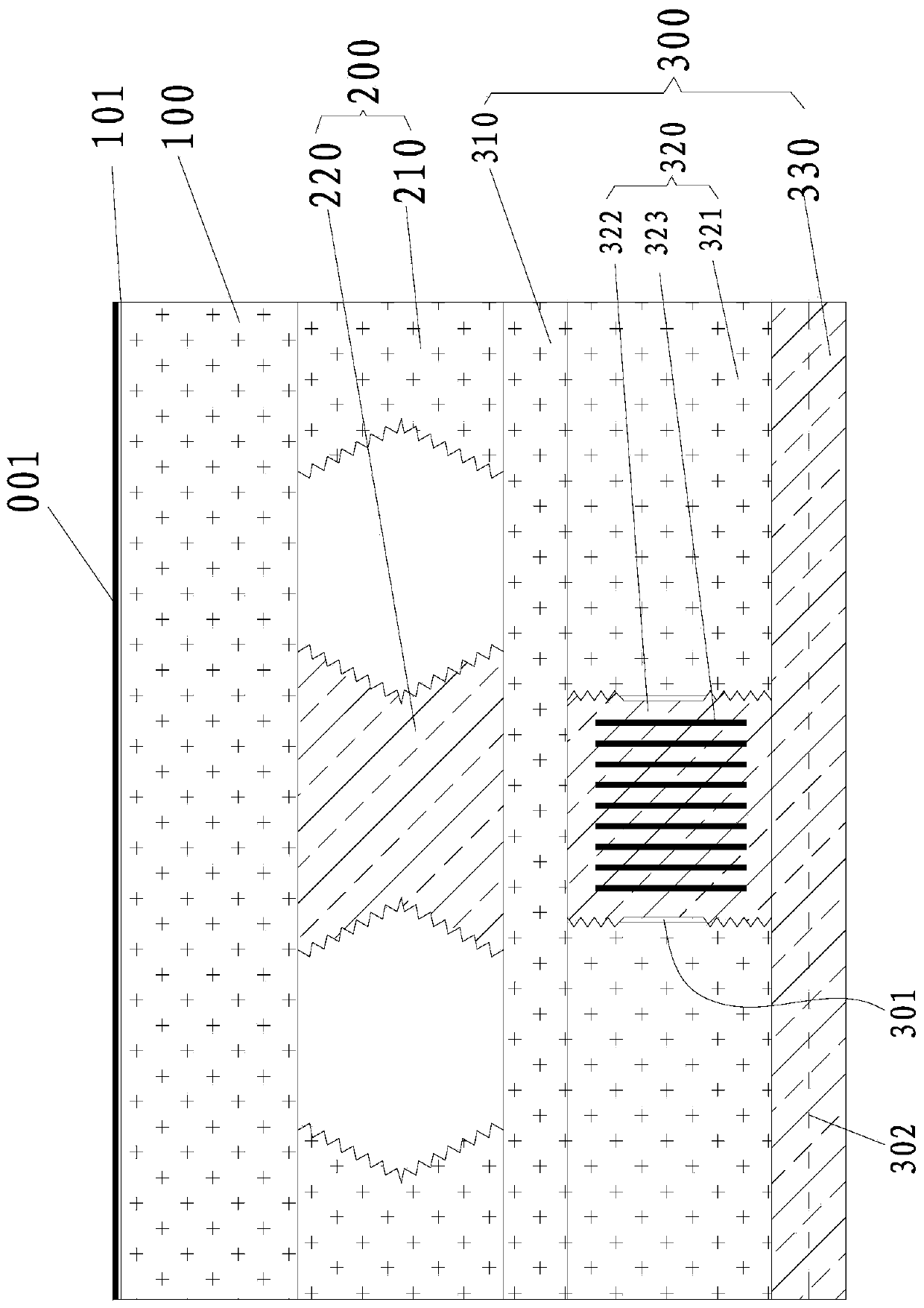

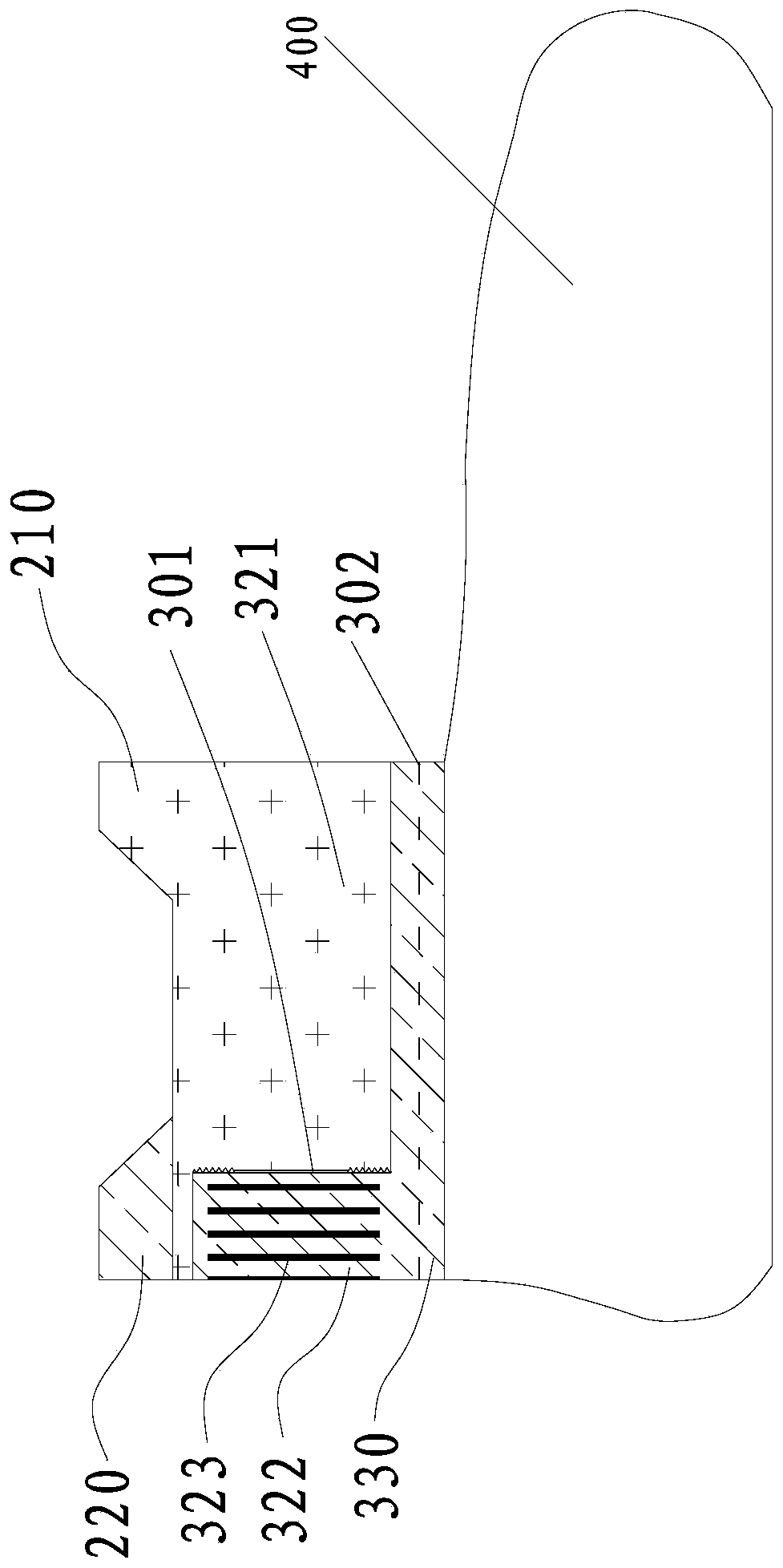

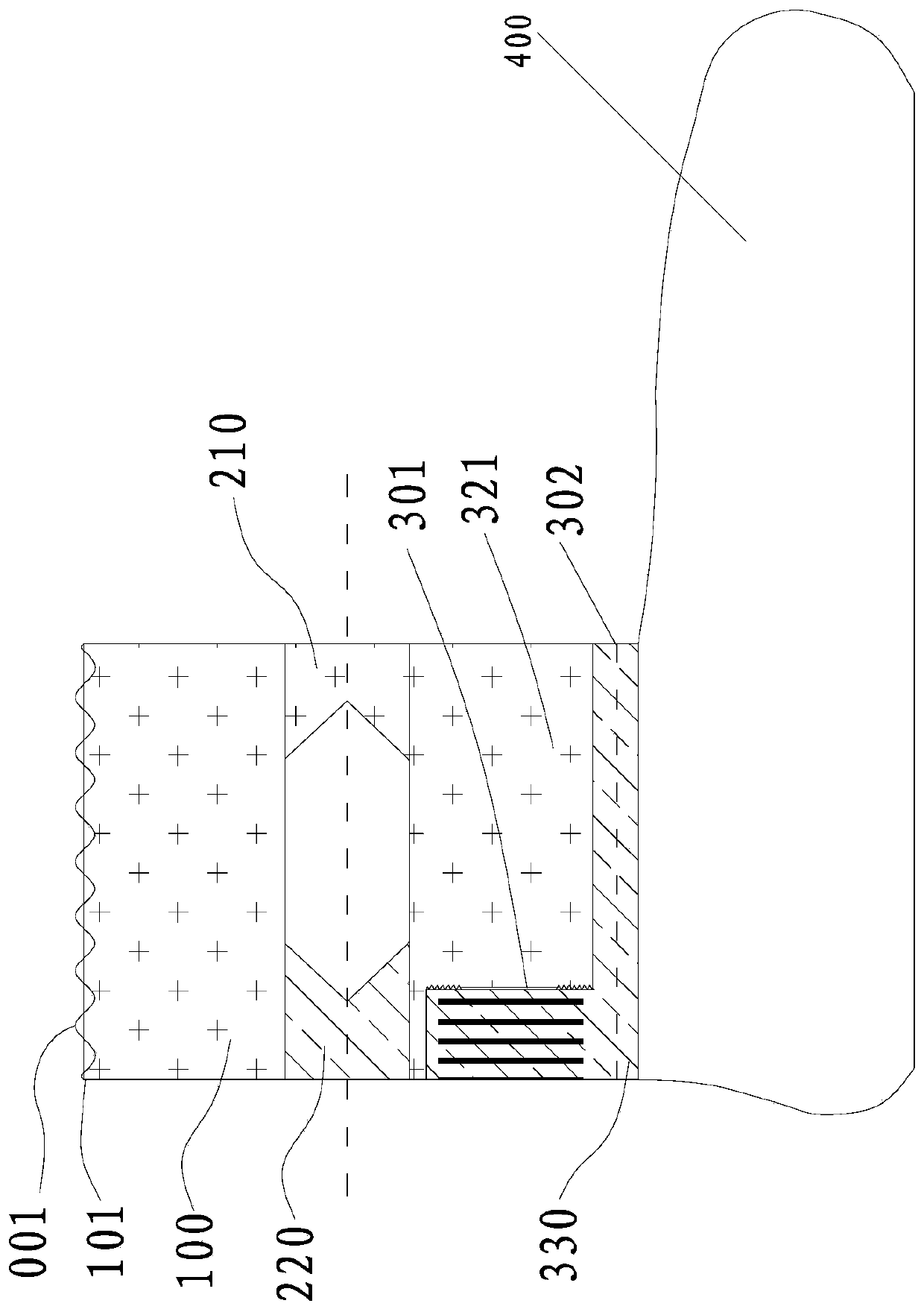

[0031] refer to Figure 1 to Figure 3 , a cuff of a knitted one-piece shoe, based on the orientation of the knitted one-piece shoe when worn, with the direction of the toe of the toe as the front, the direction of the heel as the rear, the direction of the sole as the bottom, and the direction of the cuff as the top. The cuff is a double-layer cuff formed by weaving in one piece, and the double-layer cuff includes an inner layer cuff and an outer layer cuff. The double-layer cuff has a tie 101 and a tie 302, the tie 101 is woven with an anti-off coil 001 made of elastic, the tie 101 and the tie 302 are connected, and the tie 101 and the tie 302 are located on the double The lower end of the layer mouth. The upper end of the front portion of the double-layer cuff is provided with a front tongue 210, and the upper end of the rear portion of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com