Variable-rigidity vertical vibration isolation/ seismic isolation support

A variable stiffness and vertical technology, applied in the fields of walls, disaster prevention and reduction, and construction, can solve problems such as complex settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: CN100478539A provides the technical idea of variable stiffness vibration isolation, which relies on pre-compressed springs and compensation springs to achieve. However, it has the following problems:

[0035] (1) When the compensation support is lowered, the compensation spring can participate in the work under pressure; however, the compensation spring is separated from the compensation support under normal conditions; when the compensation support moves up, how can the compensation spring participate in the work? Pull, not elaborated in the literature;

[0036] (2) Whether the preload spring can be preloaded in other ways.

[0037] The starting point of the invention of this application is to solve the second problem. The preloading in CN100478539A is initially realized by the weight of the building. Then, this method is not conducive to the installation of the support; preload.

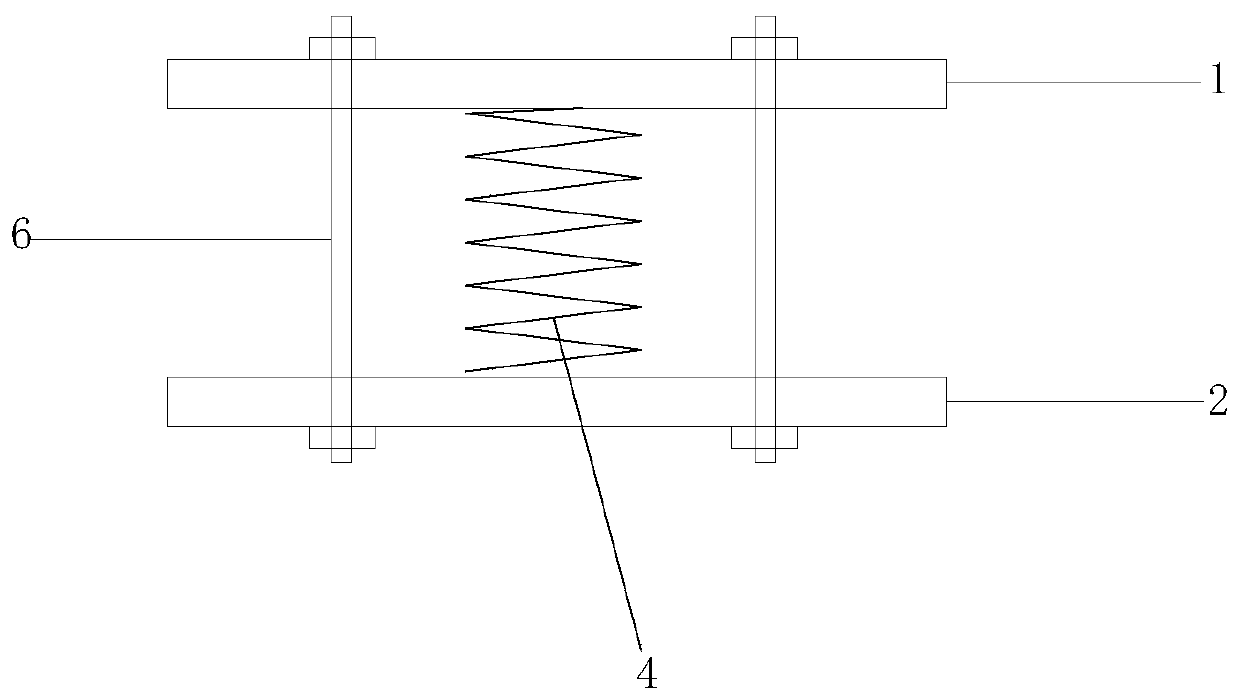

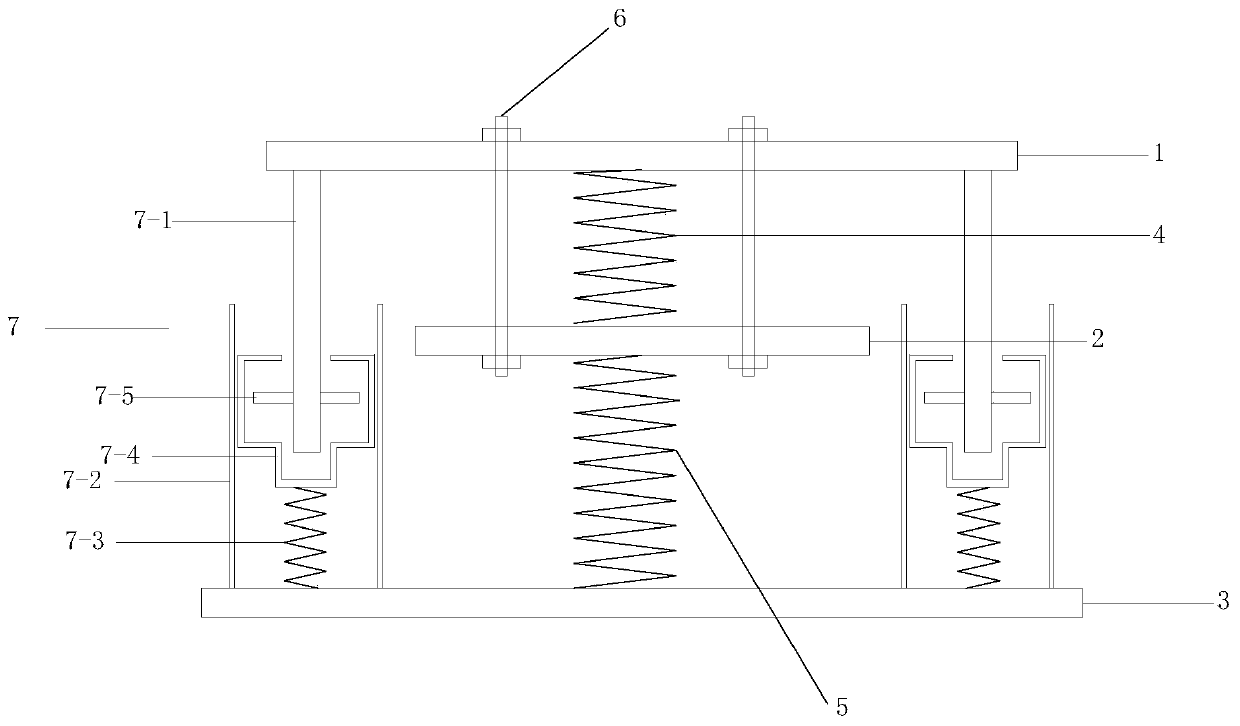

[0038] Such as figure 1 As shown, a preload spring 4 is installed be...

Embodiment 2

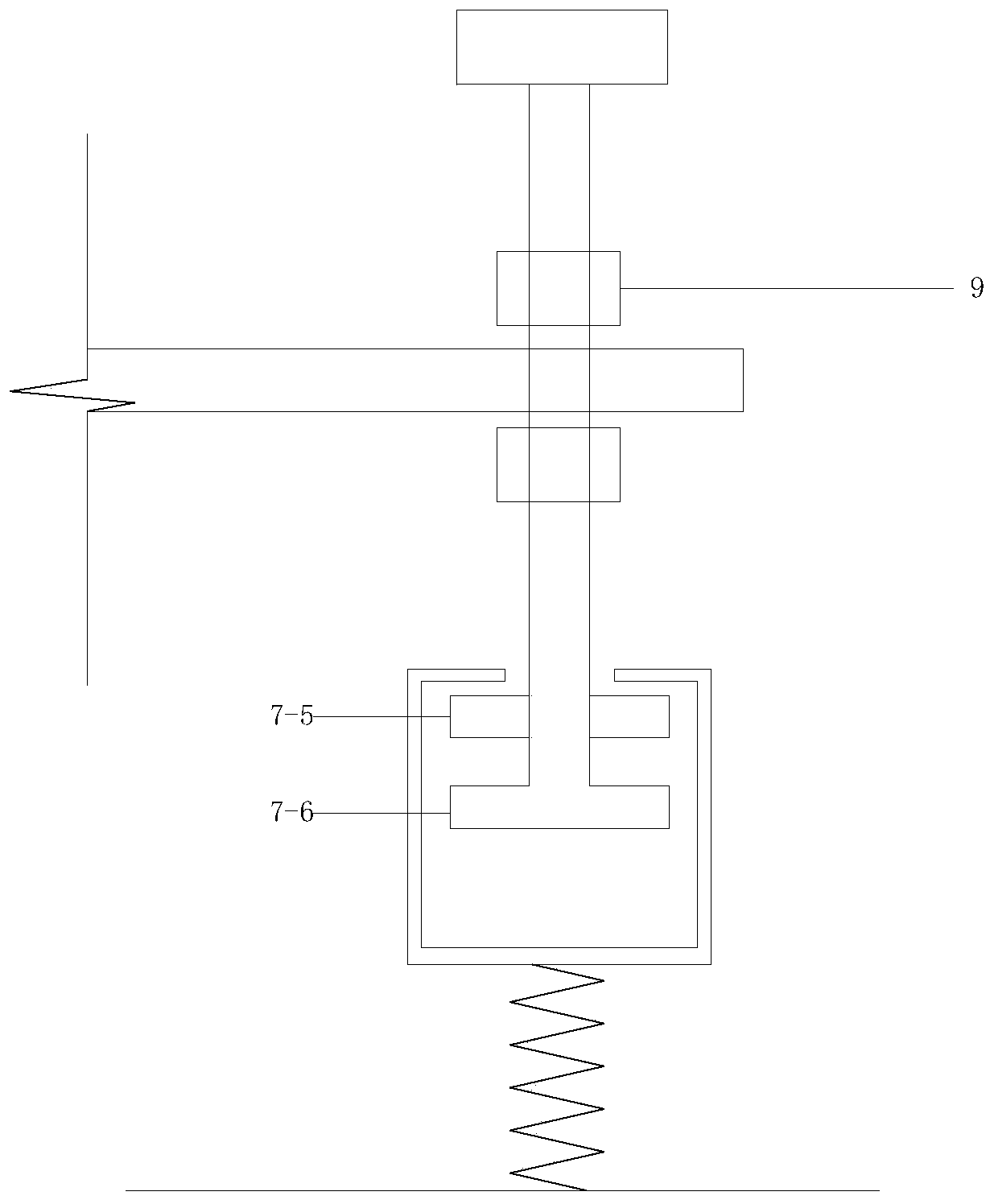

[0059] Embodiment 2, in order to make the spring participate in tension, a more reasonable design should be: in the initial state (static load), the upper surface of the protrusion 7-5 and the adjustment cavity 7-4; the difficulty lies in how to install the pressure Rod 7-1;

[0060] The pressure rod 7-1 is installed in the initial state, the pressure rod 7-1 passes through the first horizontal plate 1, the outer surface of the pressure rod 7-1 is provided with threads, and the upper part of the pressure rod 7-1 is provided with 2 threads Cap 9, two threaded caps 9 are respectively located on the top and bottom of the first horizontal plate 1, after the height of the pressure rod 7-1 is adjusted, then the two threaded caps 9 are used to clamp the pressure rod 7-1 on the first level. Horizontal plate 1, and then fix pressure bar 7-1.

[0061] Embodiment 2: In the initial state, when the distance between the bottom of the pressure rod and the adjustment cavity 7-4 is greater th...

Embodiment 3

[0065] Embodiment 3: A viscous damper 11 is installed between the first horizontal plate and the third horizontal plate, and the viscous damper is arranged on the outside of the outer wall of the sleeve 7-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com