Mounting process for solving irregular staggered joint of aluminum plates

An installation process, aluminum plate technology, applied in covering/lining, construction, building structure, etc., can solve problems such as installation failure, aluminum plate processing errors, etc., to avoid fighting, avoid rework, good economic effect and use value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

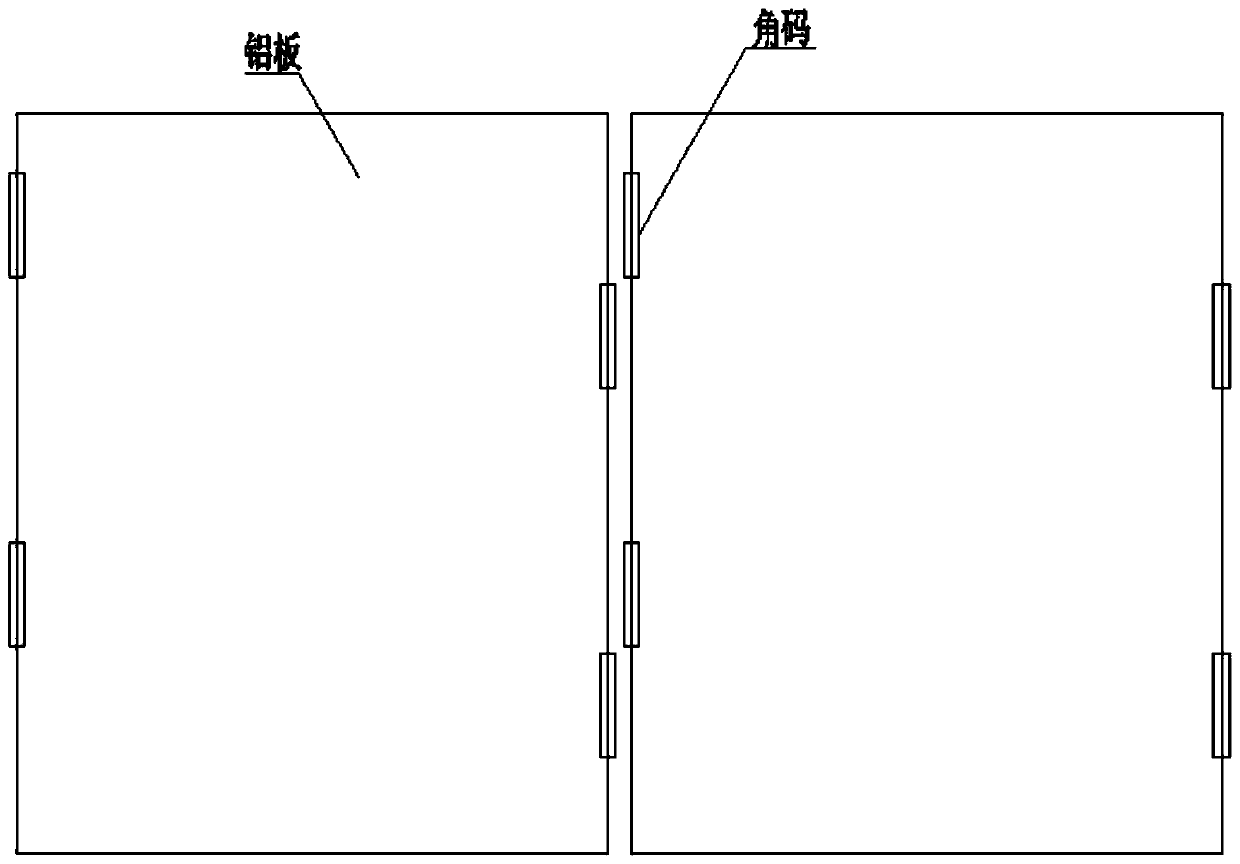

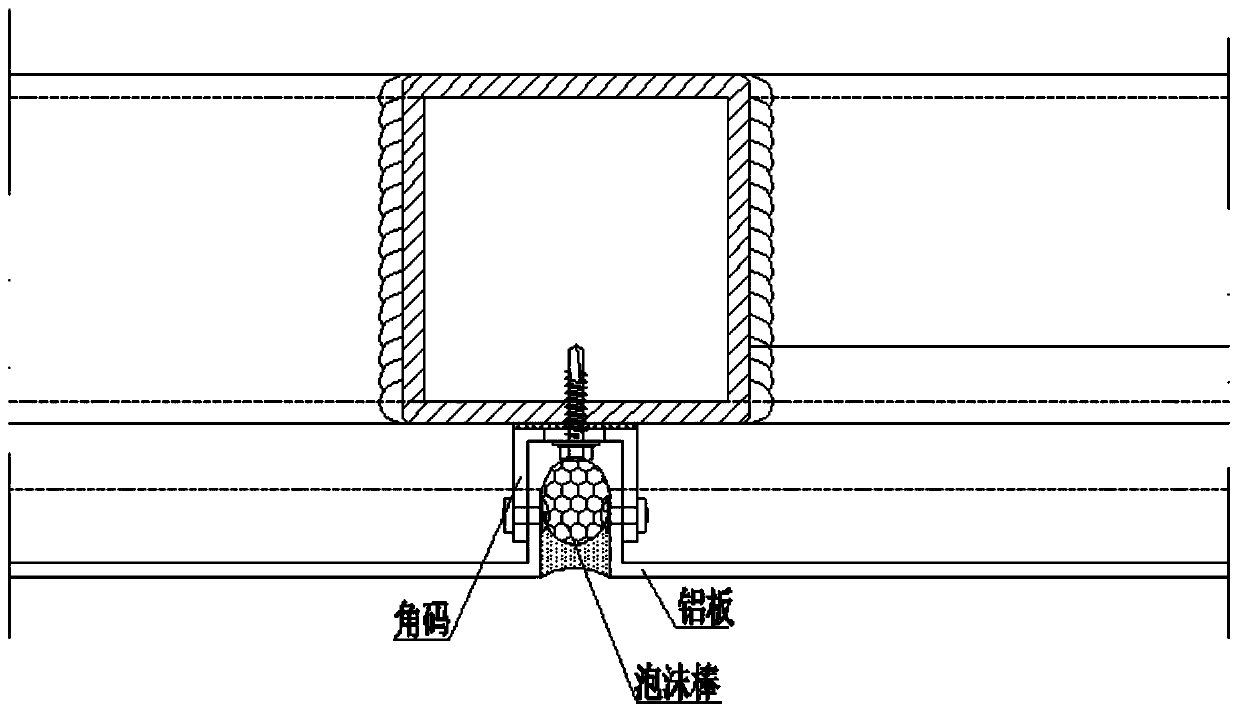

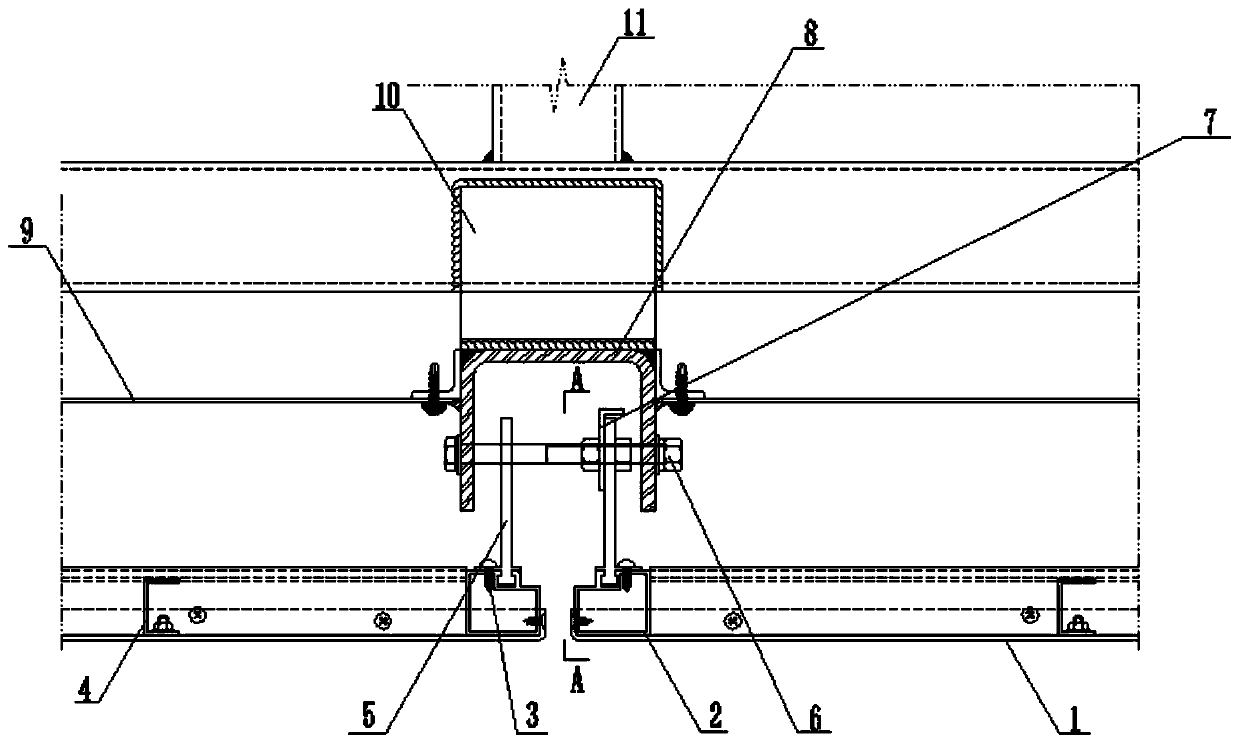

[0028] An installation process for solving irregular staggered aluminum panels, including the following installation steps:

[0029] S1, processing aluminum veneer and frame, and then connecting them into a whole;

[0030] S2, according to the design requirements, combine the aluminum alloy hook with the frame, and then install it to the position where the aluminum plate is located;

[0031] S3, after adjusting the aluminum alloy hook to a proper position, install self-tapping screws to fix the position of the aluminum alloy hook;

[0032] S4, use the outer hexagon head full bolt group to hoist the aluminum alloy hook to the corresponding position of the channel steel and then fix it;

[0033] S5, repeating the above steps S2 to S4 until the installation of all the staggered aluminum panels is completed.

[0034] Under the premise of ensuring safety, the purpose of adjustable angle steel is realized. It is suitable for various aluminum plates with split joints, avoiding the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com