Gridded high-speed railway supporting layer concrete wave velocity detection device and estimation method

A technology for high-speed railways and detection devices, which is applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc. It can solve the problem of not meeting the needs of large-area detection of concrete strength in the support layer, the inability to refine the detection of different distributions of concrete strength, and the inability to obtain concrete strength. and other problems, to achieve the effect of improving the maintenance level, refining the detection scale, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the invention, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

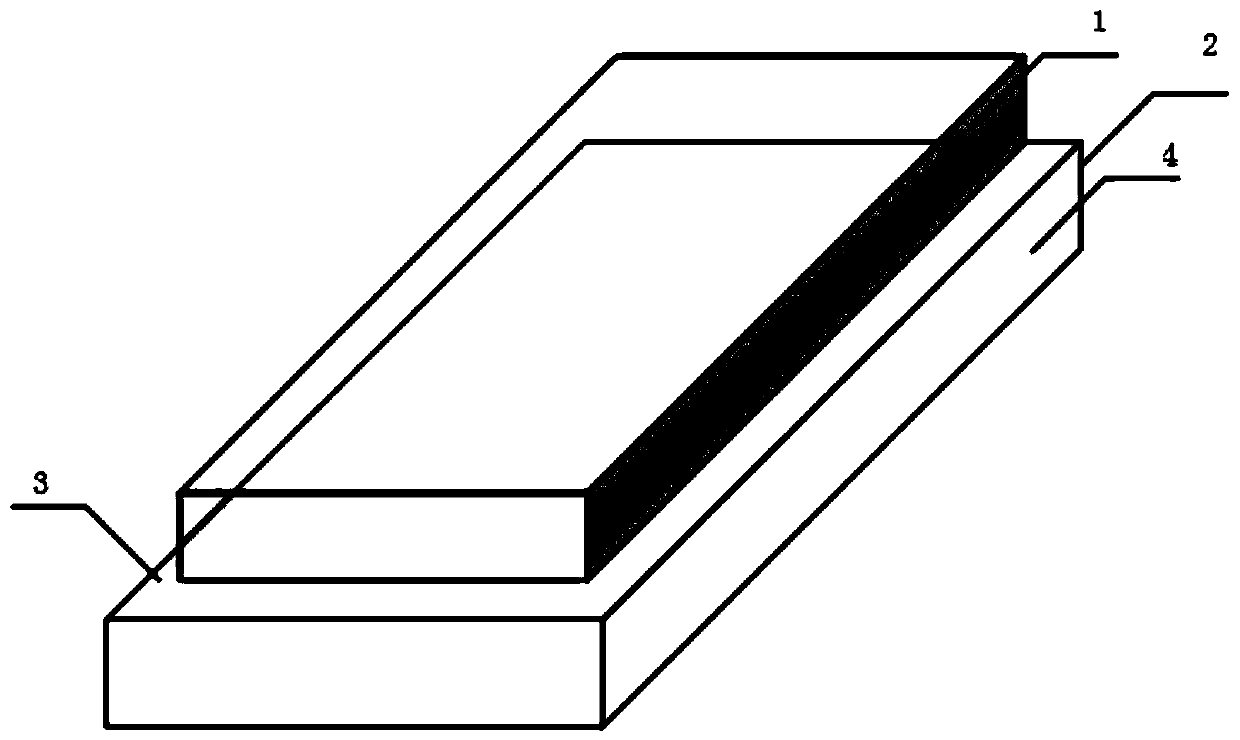

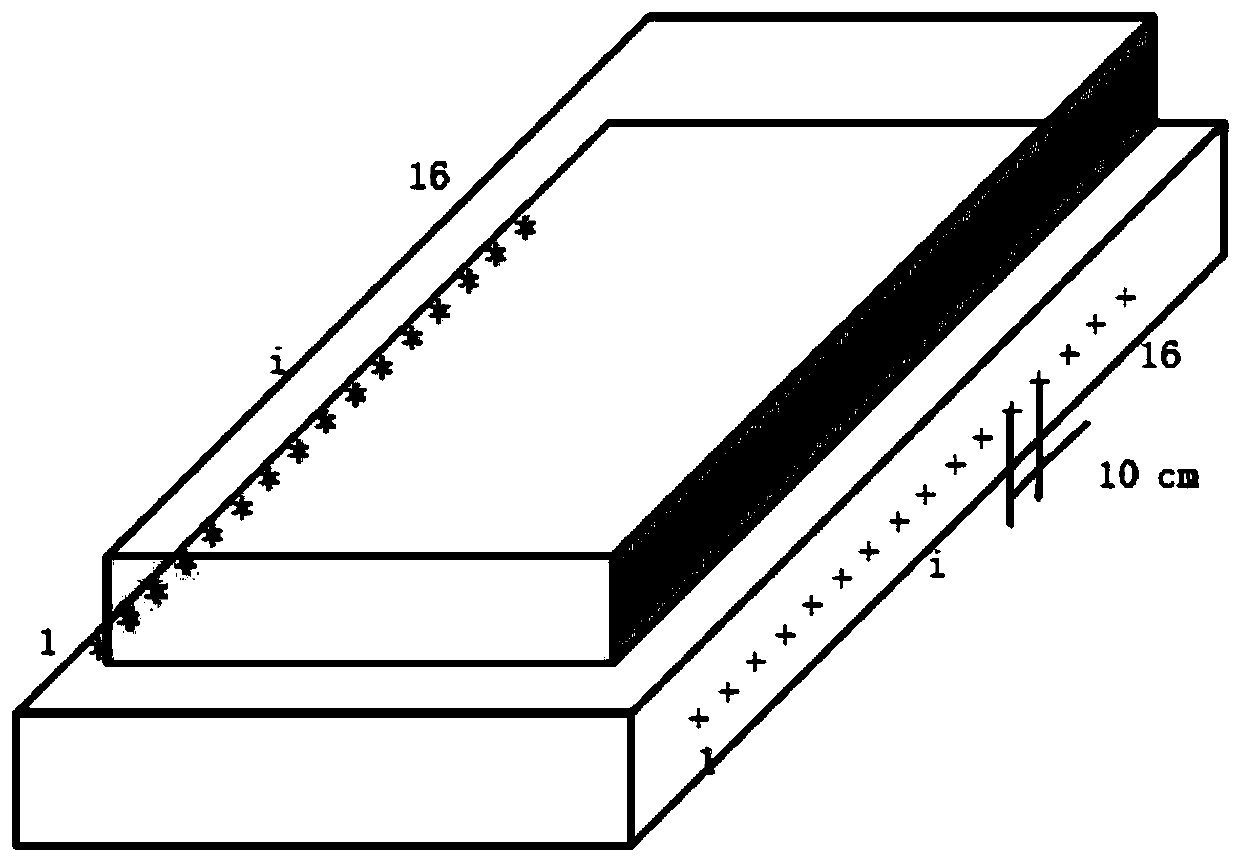

[0041] refer to Figure 1-6 , the present invention provides a gridded high-speed railway support layer concrete wave velocity detection device and estimation method, comprising a track slab 1 and a support layer 2, the track slab 1 is arranged at a middle position above the support layer 2, and the support layer 2. The upper surface is the elastic wave receiving surface 3, and the side surface of the support layer 2 along the extending direction of the track is the elastic wave excitation surface 4;

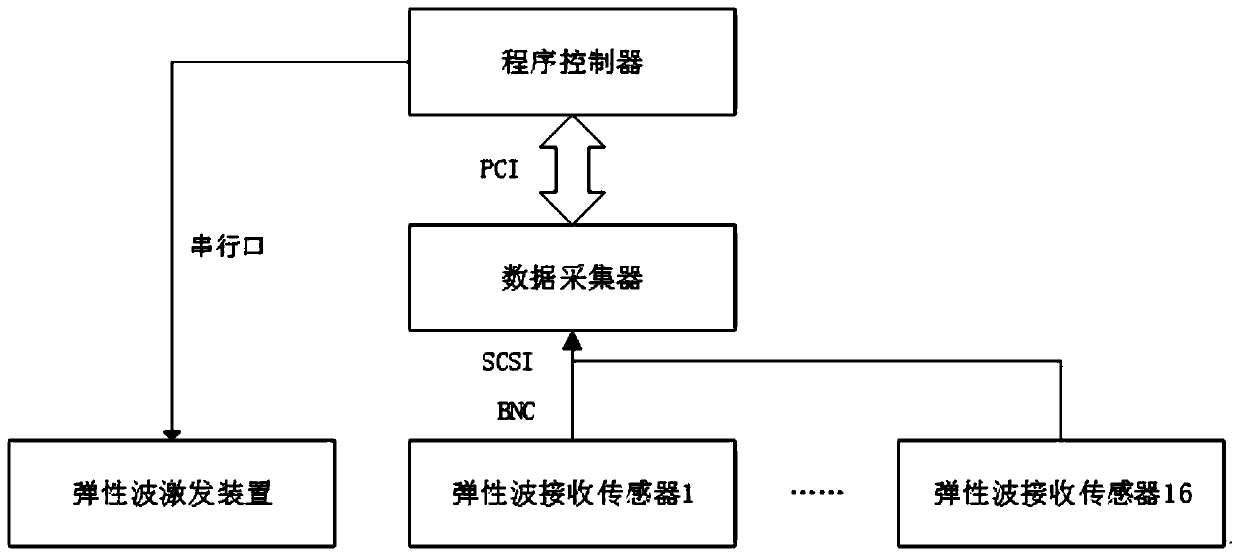

[0042] A plurality of elastic wave excitation devices are arranged horizontally at fixed intervals on the elastic wave excitation surface 4, and a plurality of elasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com