Hinge detection device of oil filling hole cover

A technology of detection device and fuel filler cap, which is applied in the direction of measurement device, mechanical measurement device, mechanical device, etc., can solve the problems of lack of effective positioning and detection error, so as to improve hinge detection performance, reduce design and manufacture, and ensure installation. The effect of using performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

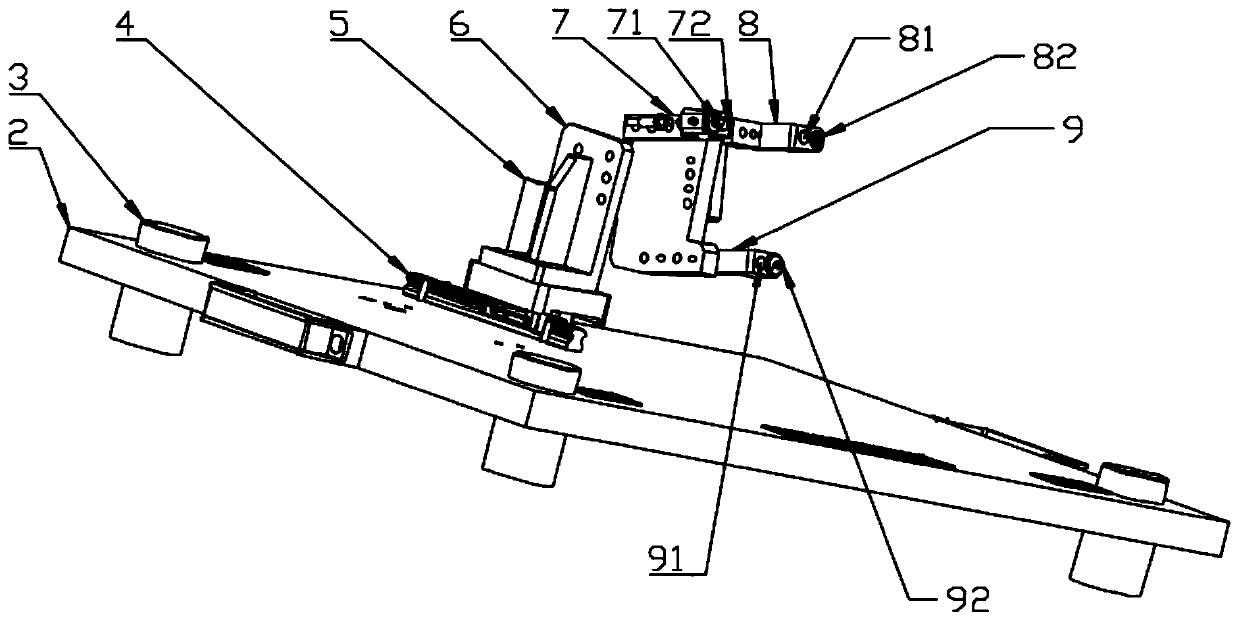

[0016]In order to describe the X, Y, Z orientation, as attached image 3 As shown, the displacement direction of the first sliding mechanism 4 is the Y direction, the vertical direction is the Z direction, and the left-right direction of the first sliding mechanism 4 is the X direction.

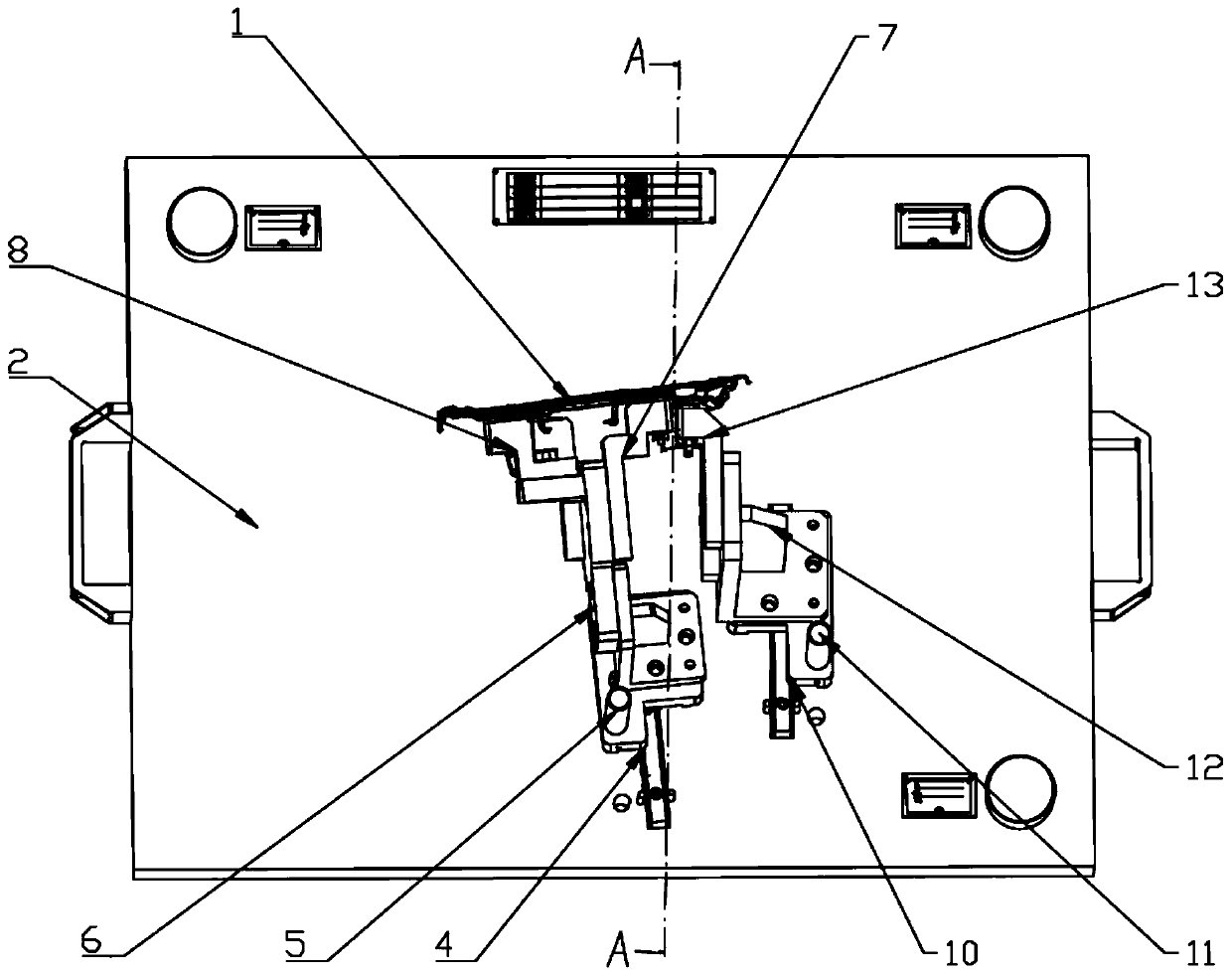

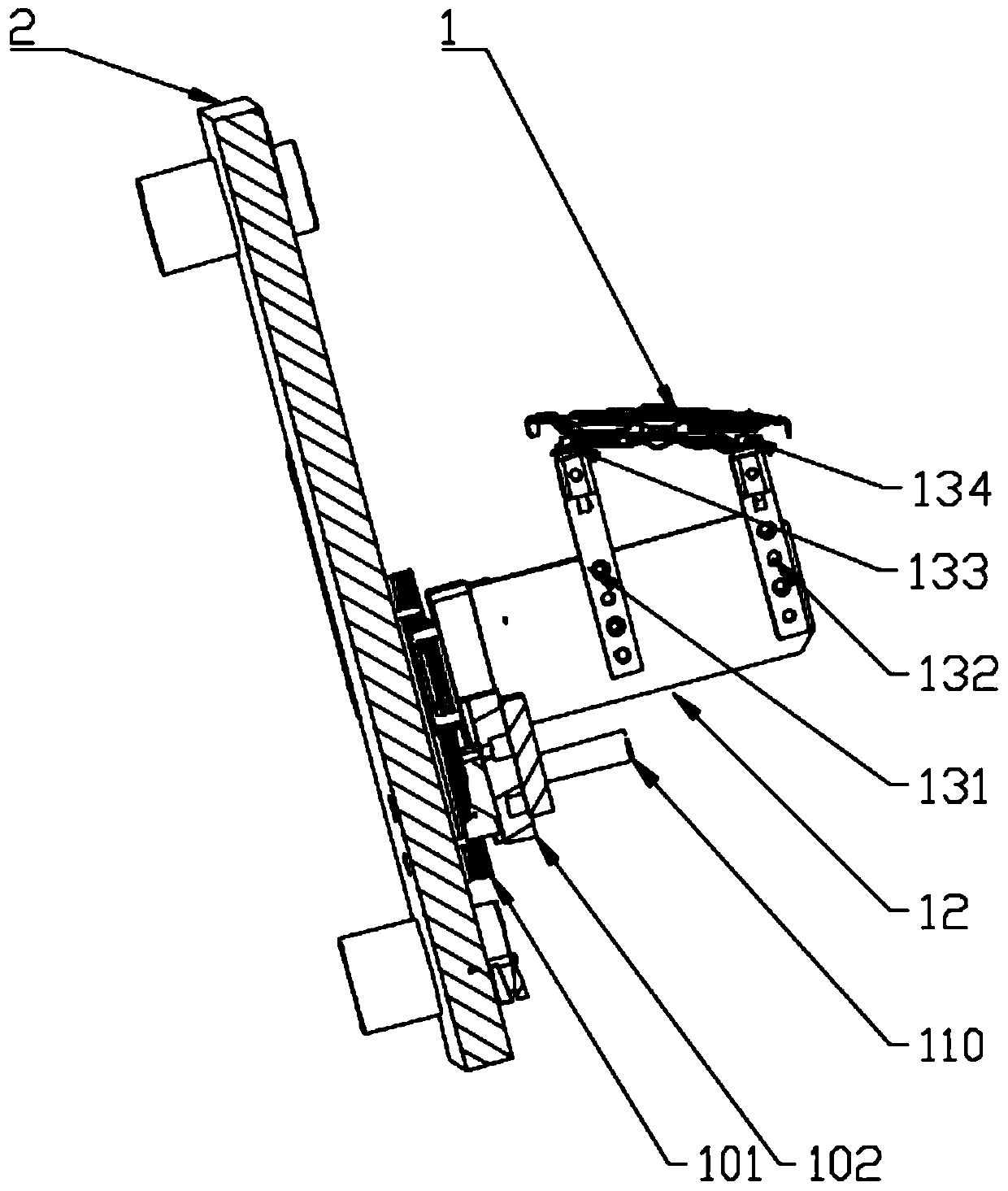

[0017] as attached figure 1 , 2 As shown in , 3 and 4, a hinge detection device for a fuel filler cap includes a base plate 2, an inner plate positioning support mechanism and a hinge detection mechanism are fixedly arranged on the base plate 2, and the inner plate positioning support mechanism includes a first sliding mechanism 4 , the first sliding mechanism 4 is fixedly provided with a first sliding mechanism positioning device 5, the first supporting mechanism 6 is also fixedly connected above the first sliding mechanism 5, and the first supporting mechanism 6 is fixedly provided with an inner plate positioning mechanism; The hinge detection mechanism includes a second sliding mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com