Electrostatic discharge protection structure and manufacture method thereof, and electronic device

A technology of electrostatic discharge protection and static electricity, which is applied in the electronic field and can solve problems such as ESD protection of soft and hard boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention provide an electrostatic discharge protection structure, a manufacturing method thereof, and electronic equipment, so as to solve the technical problem existing in the prior art that effective ESD protection cannot be performed on a rigid-flex board.

[0035] The technical solution in the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

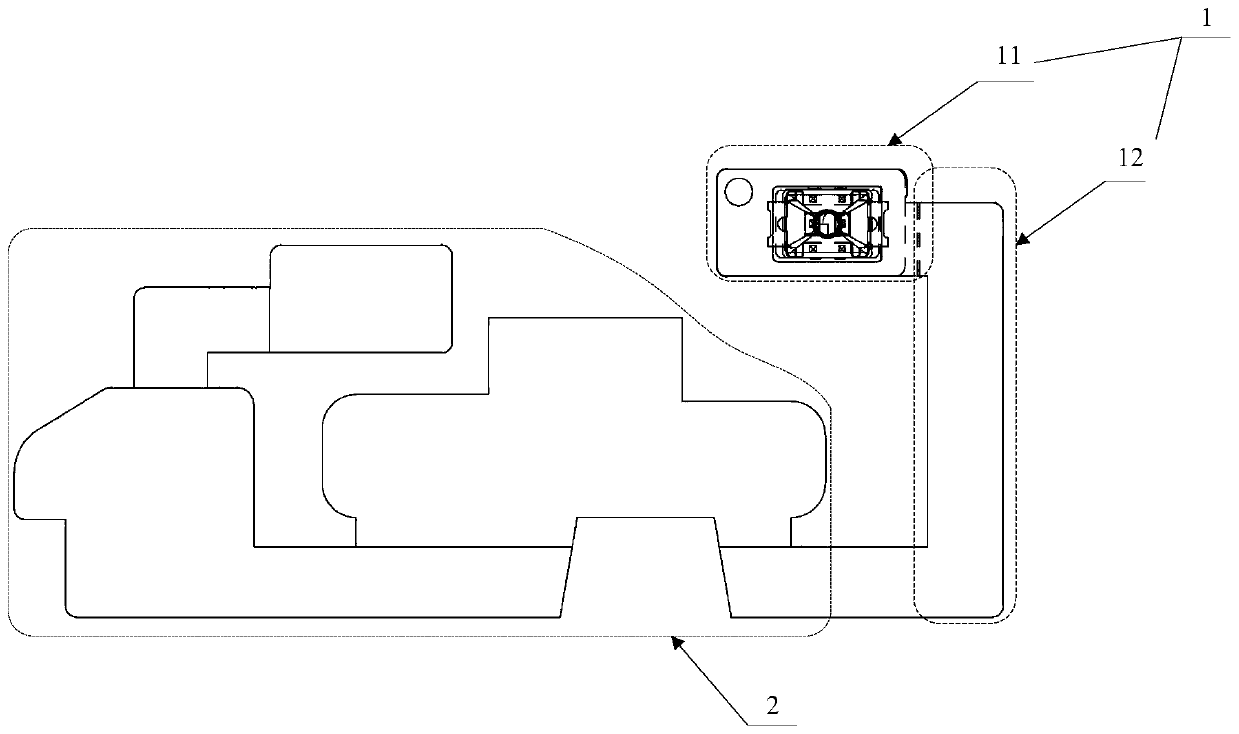

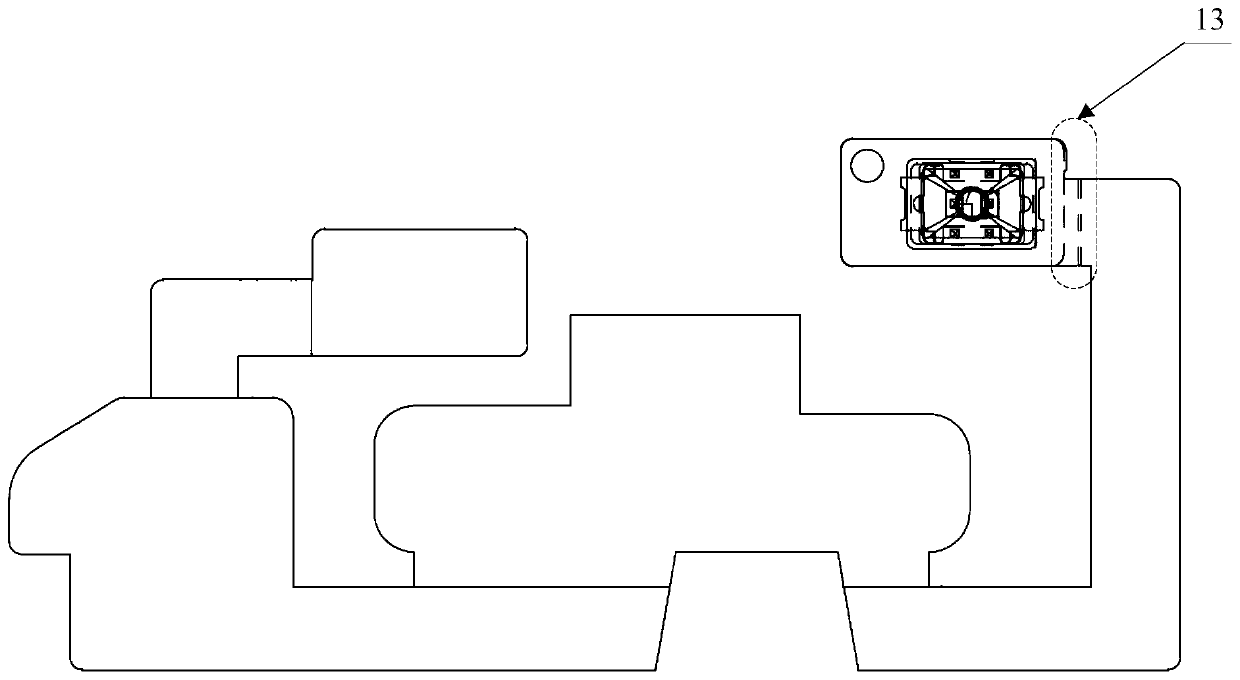

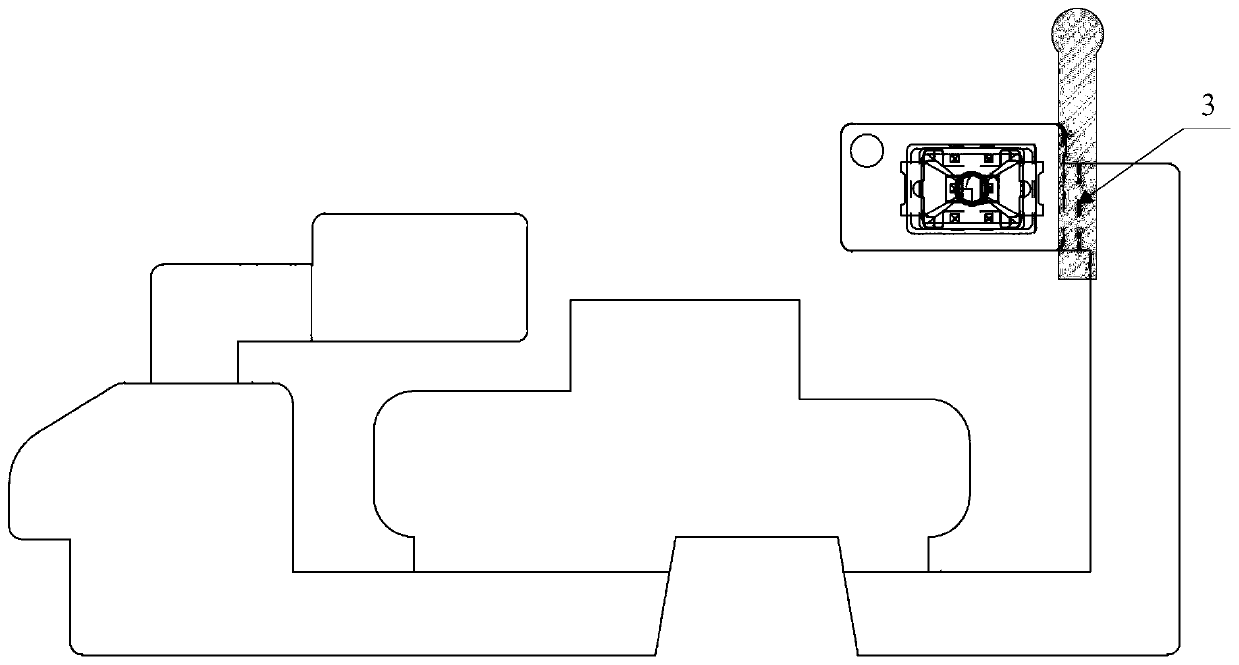

[0036] An electrostatic discharge protection structure is provided, which is applied to a rigid-flex board. The rigid-flex board includes a flexible board and a rigid board. At the junction of rigid boards, the width of the flexible plane conductor is not less than the width of the flexible board; wherein, the bonding surface where the flexible plane conductor is located is the side facing the object that generates electrostatic discharge, and is used to discharge the static electricity generated by the object that generates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com