Seed screening device

A screening device and technology for seeds, applied in the direction of sieve, solid separation, grid, etc., can solve the problems of inability to directly remove light debris from seeds, affecting seed emergence and production and development, and incomplete screening and grading process. Increase three-dimensional flow effect, light weight, reduce breakage rate and impurity rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention.

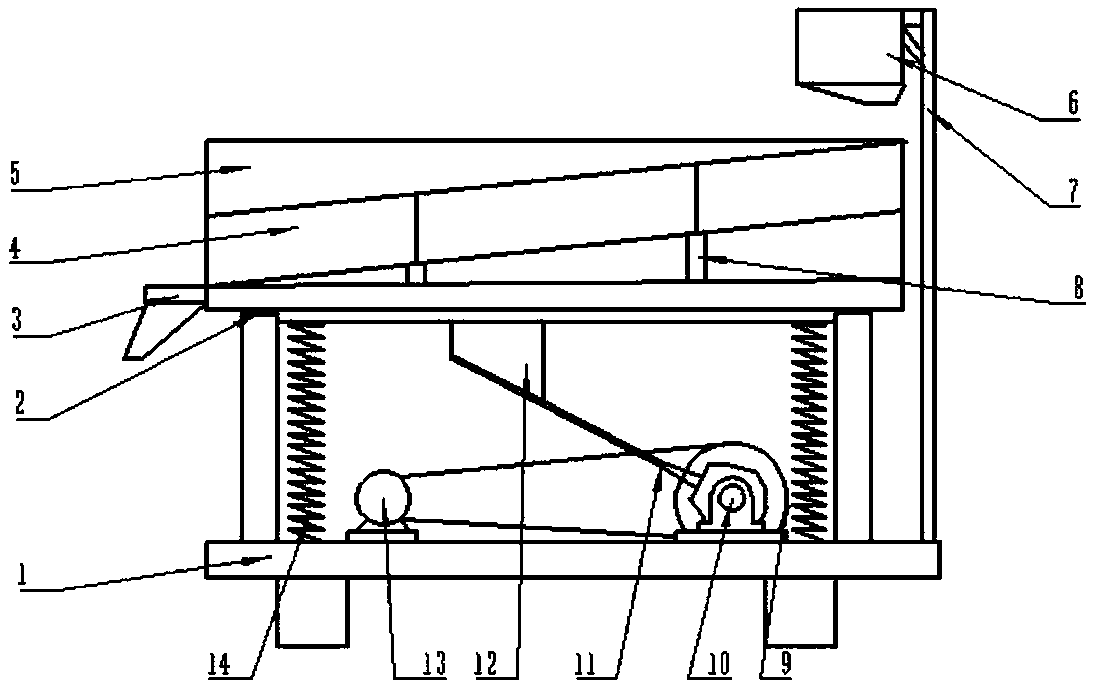

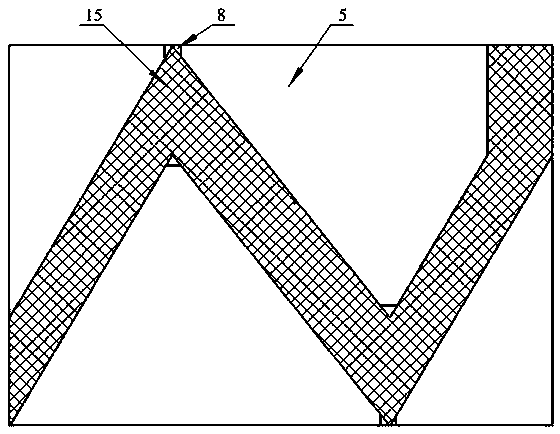

[0018] A seed screening device such as figure 1 Shown, comprise frame 1, described frame 1 top two ends are all provided with column 16; Described column 16 tops are provided with casing 5; Described column 16 tops are all provided with rubber backing plate 2, play certain buffering effect; the box body 5 is provided with a screen 15, such as figure 2 As shown, the screen 15 is Z-shaped, and the two ends of the screen 15 are fixed on the inner surface of the box body 5, and the turning portion on the screen 15 passes through the screen stabilizing frame 8 and the inside of the box 5. The bottom surface is fixed; both sides of the screen 15 are provided with inclined panels 4, so that the screen 15 at the bottom and the inclined panels 4 on both sides form a seed flow channel space; The disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com