A self-balancing multi-position sustainable vibration device

A continuous vibration, multi-station technology, used in solid separation, chemical instruments and methods, grids, etc., can solve problems such as single vibration combined frequency mode, unbalanced vibration force of bed frame, and unstable vibration of bed structure. , to increase durability, improve long-term continuity and stability, improve efficiency and diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

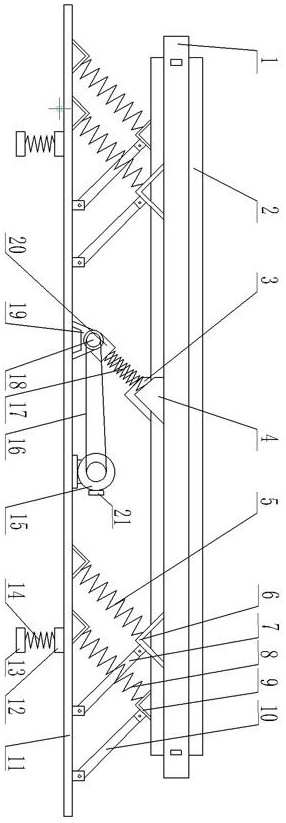

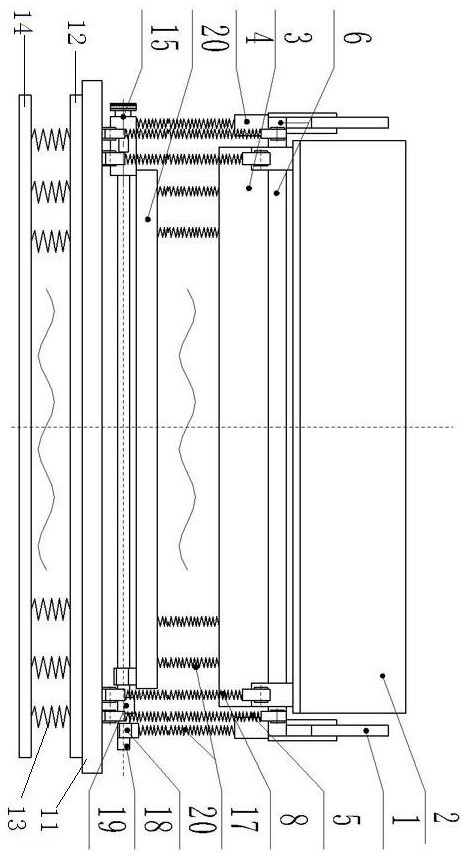

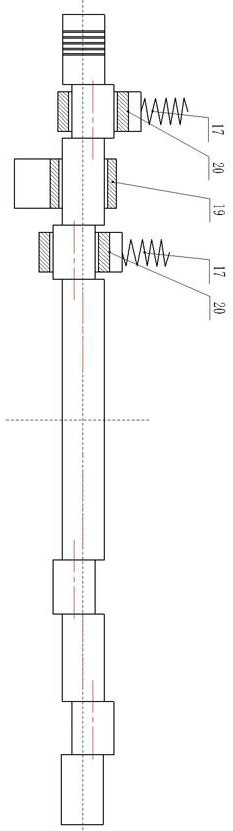

[0026] The implementation of the technical solution will be further described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0027] Such as Figure 1~4 One embodiment shown is a self-balancing multi-station sustainable vibrating device, including a vibrating bed 2 and a balance beam 1 arranged on both sides thereof, and the balance beam 1 and the supporting beam 11 below the vibrating bed 2 are made A drive mechanism is set on the support beam 11, and the drive mechanism includes an eccentric crankshaft 18 and an exciting spring 17. The balance beam 1 and the vibrating bed 2 are respectively connected with the eccentric crankshaft 18 through the exciting spring 17. The eccentric crankshaft 18 It is symmetrical at both ends, and each end sleeve includes an outer shaft body 181, an inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com