Automatic piece outlet grading stamping die of book sewer central bracket and forming method of automatic piece outlet grading stamping die

A technology of central bracket and stamping die, which is applied in the field of stamping dies, can solve the problems of low forming precision, difficulty in mass production, and difficulty in automatic output, and achieve the effects of length reduction, production efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

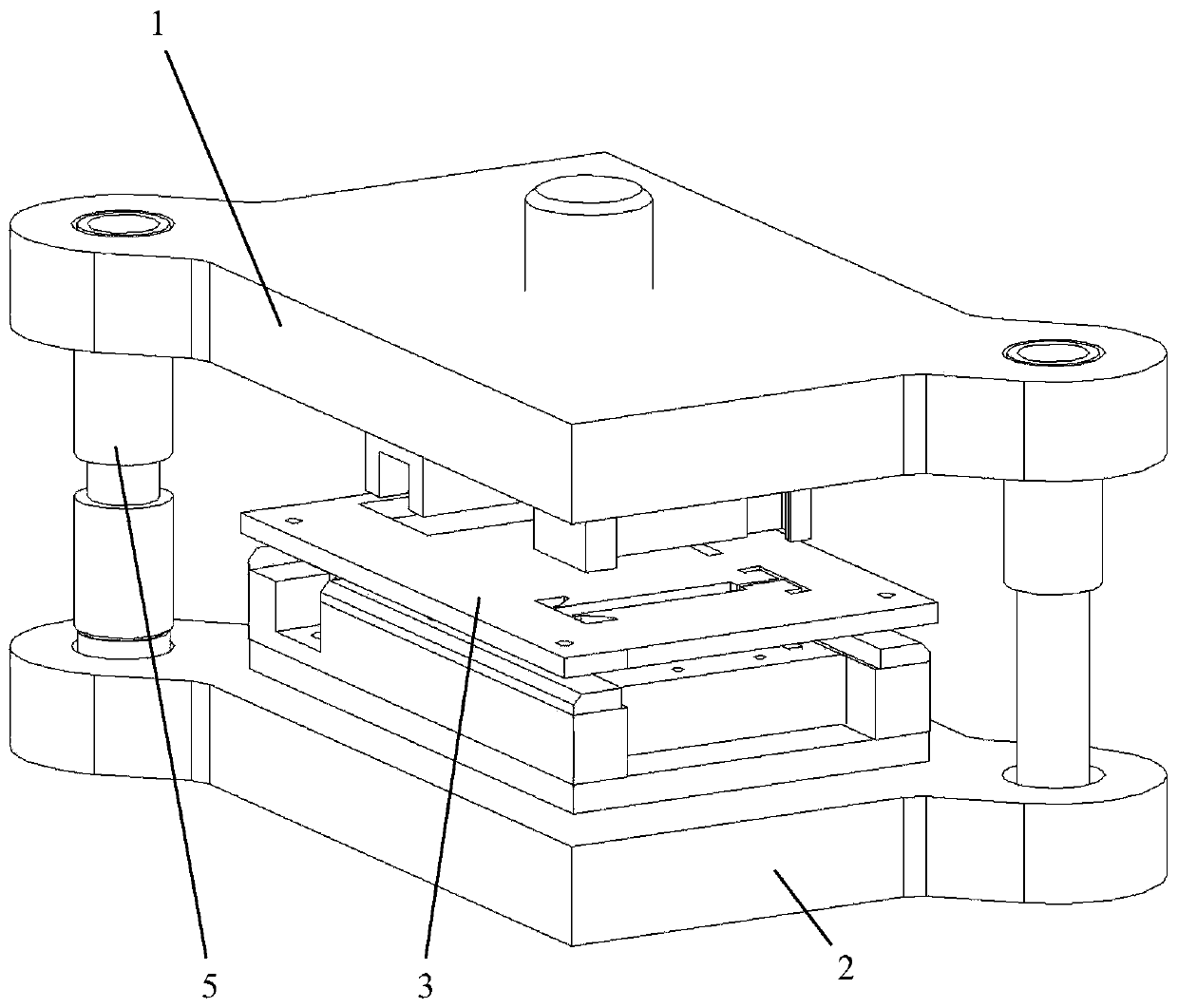

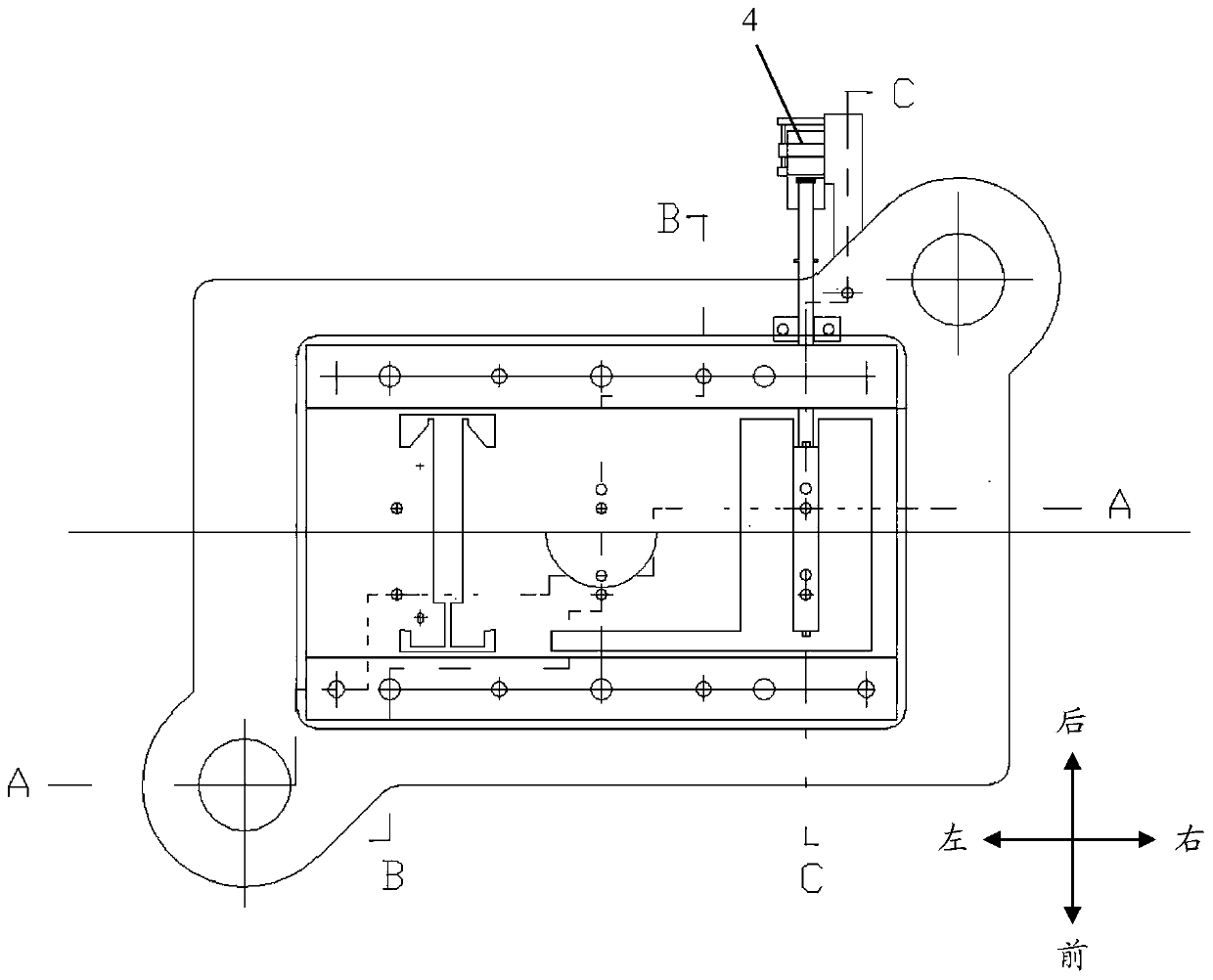

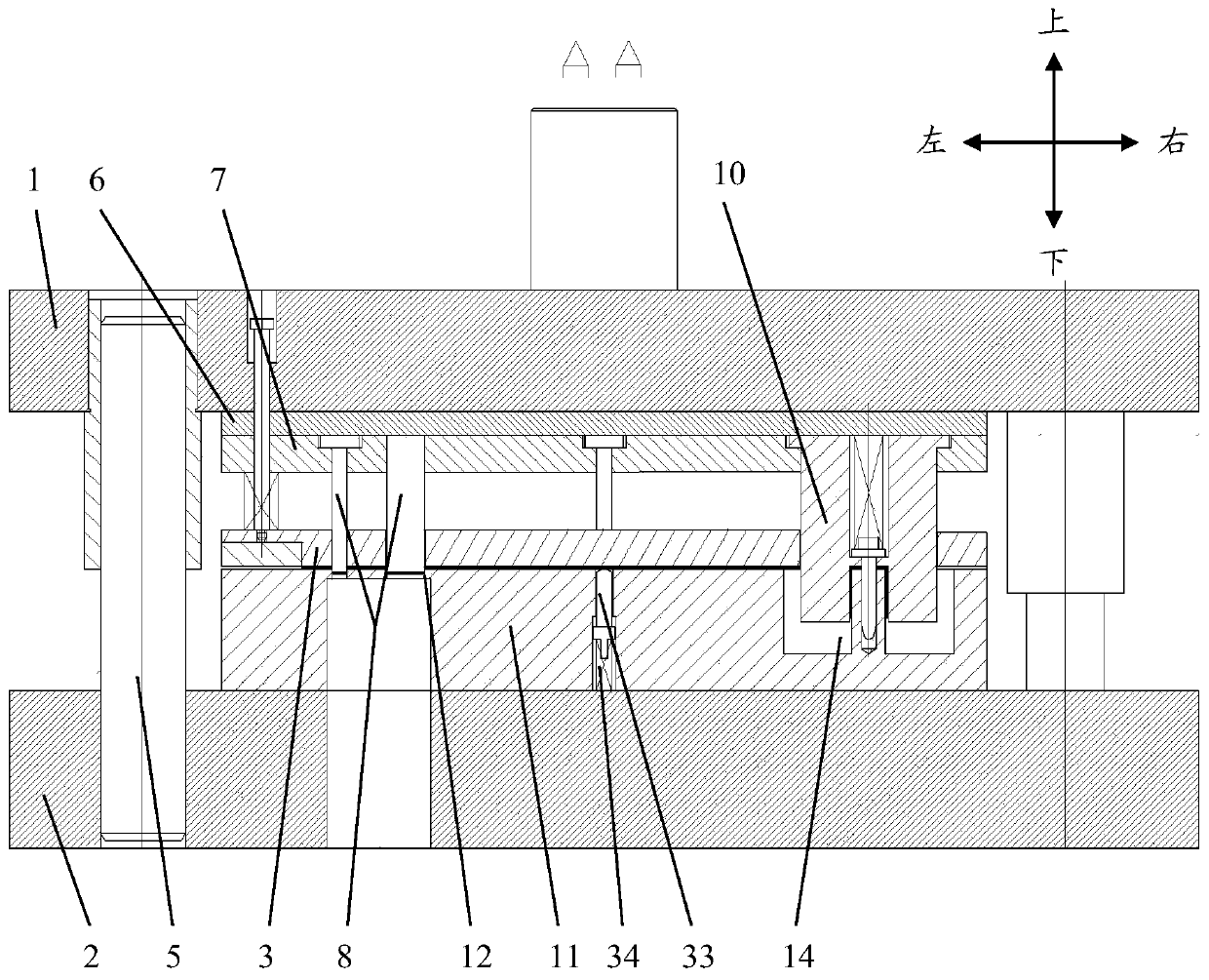

[0050] see Figure 1 to Figure 6 , the embodiment of the present invention discloses a progressive stamping die for automatic ejection of the central bracket of a stapler, including: an upper die base 1 and a lower die base 2 arranged up and down, a discharge plate 3 and a discharge device 4;

[0051] Among them, the upper mold base 1 and the lower mold base 2 are connected by a guide device 5, the guide device 5 is arranged diagonally, and the guide device 5 is a sliding guide method, and the structure arranged diagonally can better constrain the longitudinal precision of the guide, Good coaxiality;

[0052] The backing plate 6 and the upper mold fixing plate 7 are connected successively below the upper die base 1, the upper die base 1, the backing plate 6 and the upper die fixing plate 7 are fixedly connected by screws, and the backing plate 6 and the upper die fixing plate 7 are installed with The punch group protruding downwards, the punch group includes punching punch gr...

Embodiment 2

[0088] see Figure 1 to Figure 6 , the embodiment of the present invention discloses a forming method for the central bracket of a stapler that is automatically ejected and progressively entered into a stamping die, specifically comprising the following steps:

[0089] Step 1: The automatic feeding device sends the strip material from left to right to the top of the concave template 11 at a constant speed, and controls the feeding direction through the material guide plate;

[0090] Step 2: The upper mold base 1 moves down, and when the unloading plate 3 presses the belt material, the punching punch group 8, the L-shaped bending punch 9 and the U-shaped bending punch 10 contact the belt material, and continue to enter the concave formwork 11 until the mold closing is completed, at this time, the punching punch group 8 completes the profile blanking and punching, the L-shaped bending punch 9 completes the L-shaped bending, and the U-shaped bending punch 10 completes the U-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com