Novel half block automatic opening mold structure

A technology of automatic opening and half block, which is applied in the field of new half block automatic opening mold structure, can solve the problems of long auxiliary time and low efficiency, and achieve the effect of high production efficiency and low labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

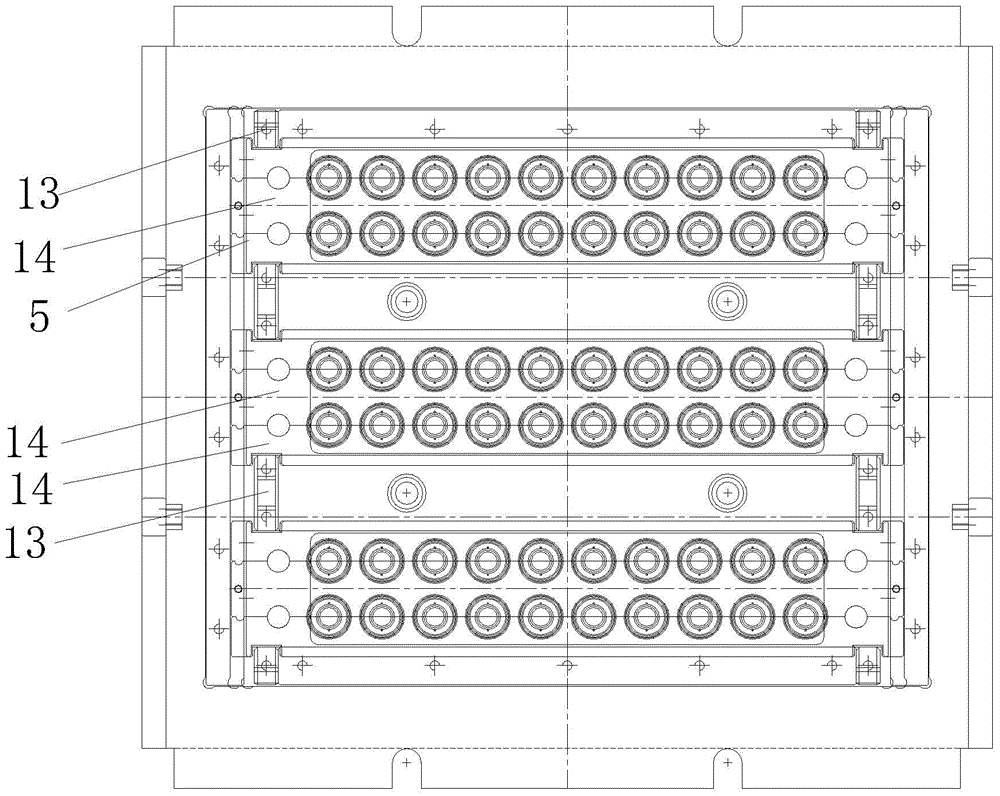

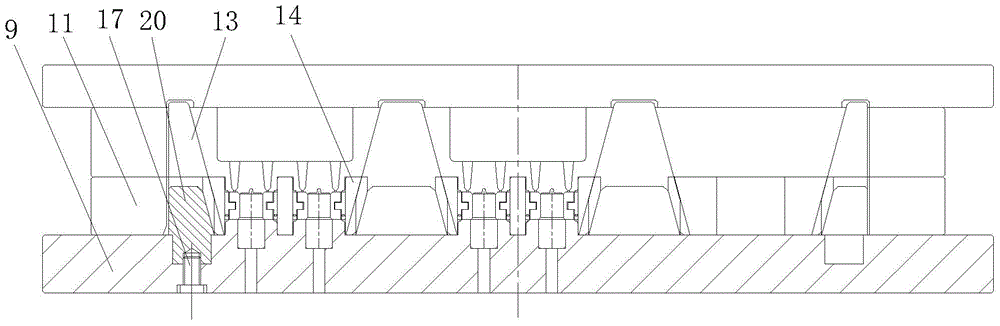

[0011] Such as figure 1 and figure 2 As shown, a novel half block automatic mold opening structure described in the present invention is composed of half bars 14, springs 5, guide wedges 13, wedges 20, bolts 17, lower die 9 and middle die 11. The above-mentioned spring 5 is located between the two half bars 14, the guide wedge 13 is located at the left and right positions of the half, the whole half bar 14 is matched by the wedge 20, and the guide wedge 13 and the wedge 20 are assembled on the lower die through the bolt 17 9, the middle mold 11 is located on the lower mold 9. The guide wedges 13 play a guiding role. The preloaded length of the spring 5 is selected according to the outer diameter of the entire structure. The angle and mating surface length of the guide wedge 13 are designed according to the outer diameter of the entire structure.

[0012] When in use, by adding springs 5 between the half bars 14 and adding guide wedges 13 with long mating surfaces at bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com