Bidirectional movable clamping plates of automobile welding robot

A technology of welding robot and movable splint, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inconvenient use, inability to angle, and limitation, etc., and achieves convenience in use and improvement of application diversity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

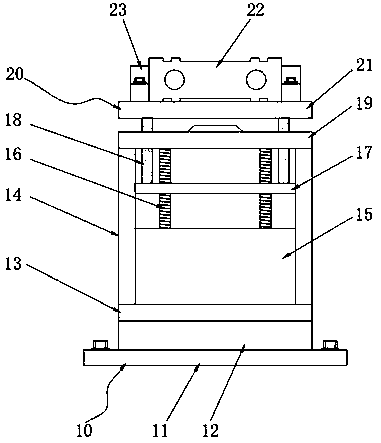

[0030] A bidirectional movable splint for a welding robot for automobiles, including a bottom adjustment assembly 10 and a top adjustment assembly 20, the bottom adjustment assembly 10 includes a square bottom plate 11, a rotating circular rail 12, a lower fixed plate 13, a support frame 14, a motor box 15, Screw rod 16, slide plate 17, slide rod 18 and upper fixed plate 19, rotating circular rail 12 is fixedly connected to the top surface of square bottom plate 11, lower fixed plate 13 is connected to rotating circular rail 12, and support frame 14 is fixedly connected to the lower fixed plate. The top surface of the plate 13, the top surface of the rotating circular rail 12 is provided with a chute 121, the bottom surface of the lower fixed plate 13 is fixedly connected with a profiling slider 131, and the profiling slider 131 is slidably connected with the chute 121. The sliding connection between block 131 and chute 121 realizes the rotation of lower fixed plate 13, thereby...

Embodiment 2

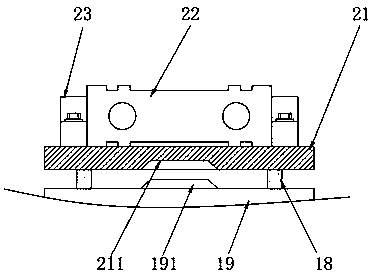

[0033]A bidirectional movable splint for a welding robot for automobiles, including a bottom adjustment assembly 10 and a top adjustment assembly 20, the bottom adjustment assembly 10 includes a square bottom plate 11, a rotating circular rail 12, a lower fixed plate 13, a support frame 14, a motor box 15, Screw rod 16, slide plate 17, slide rod 18 and upper fixed plate 19, rotating circular rail 12 is fixedly connected to the top surface of square bottom plate 11, lower fixed plate 13 is connected to rotating circular rail 12, and support frame 14 is fixedly connected to the lower fixed plate. The top surface of the plate 13, the motor box 15 is fixedly connected to the top surface of the lower fixed plate 13, the screw rod 16 is connected to the motor box 15 in rotation, the sliding plate 17 is screwed to the screw rod 16, and the sliding rod 18 is fixedly connected to the top surface of the sliding plate 17 , the screw rod 16 is rotationally connected with the motor case 15 ...

Embodiment 3

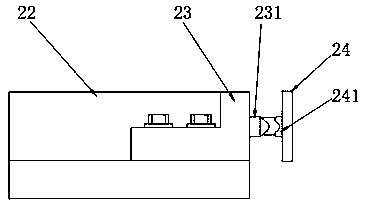

[0035] A bidirectional movable splint for a welding robot for automobiles, including a bottom adjustment assembly 10 and a top adjustment assembly 20, the bottom adjustment assembly 10 includes a square bottom plate 11, a rotating circular rail 12, a lower fixed plate 13, a support frame 14, a motor box 15, Screw rod 16, slide plate 17, slide rod 18 and upper fixed plate 19, rotating circular rail 12 is fixedly connected to the top surface of square bottom plate 11, lower fixed plate 13 is connected to rotating circular rail 12, and support frame 14 is fixedly connected to the lower fixed plate. The top surface of the plate 13, the motor box 15 is fixedly connected to the top surface of the lower fixed plate 13, the screw rod 16 is connected to the motor box 15 in rotation, the sliding plate 17 is screwed to the screw rod 16, and the sliding rod 18 is fixedly connected to the top surface of the sliding plate 17 , the upper fixing plate 19 is fixedly connected to the top surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com