Energy-mixing atomization device

An atomization device and energy mixing technology, which is applied in the directions of household heating, space heating and ventilation details, heating methods, etc. problems, to achieve the effect of improving cleanliness, wide application range, and speeding up evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

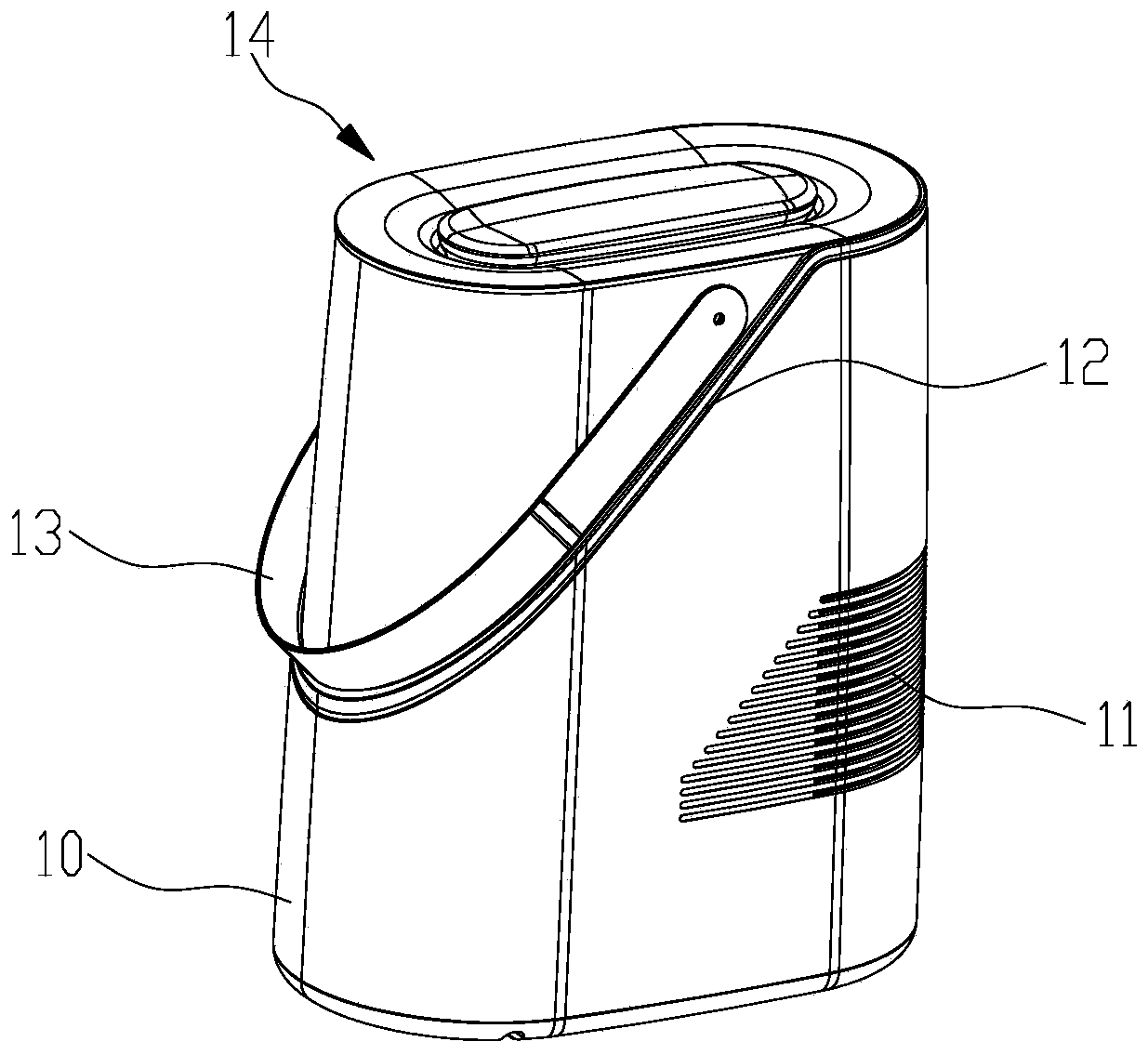

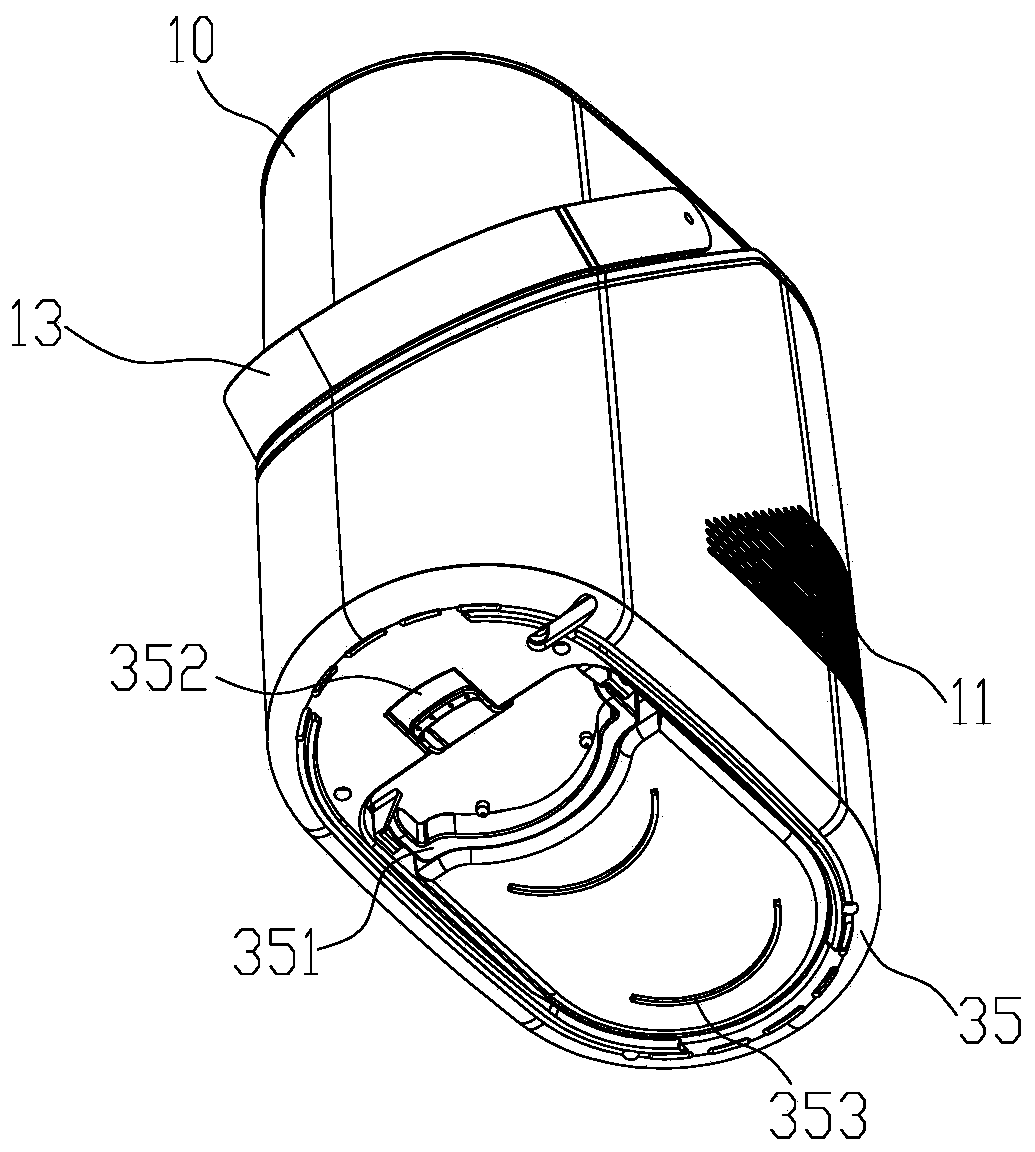

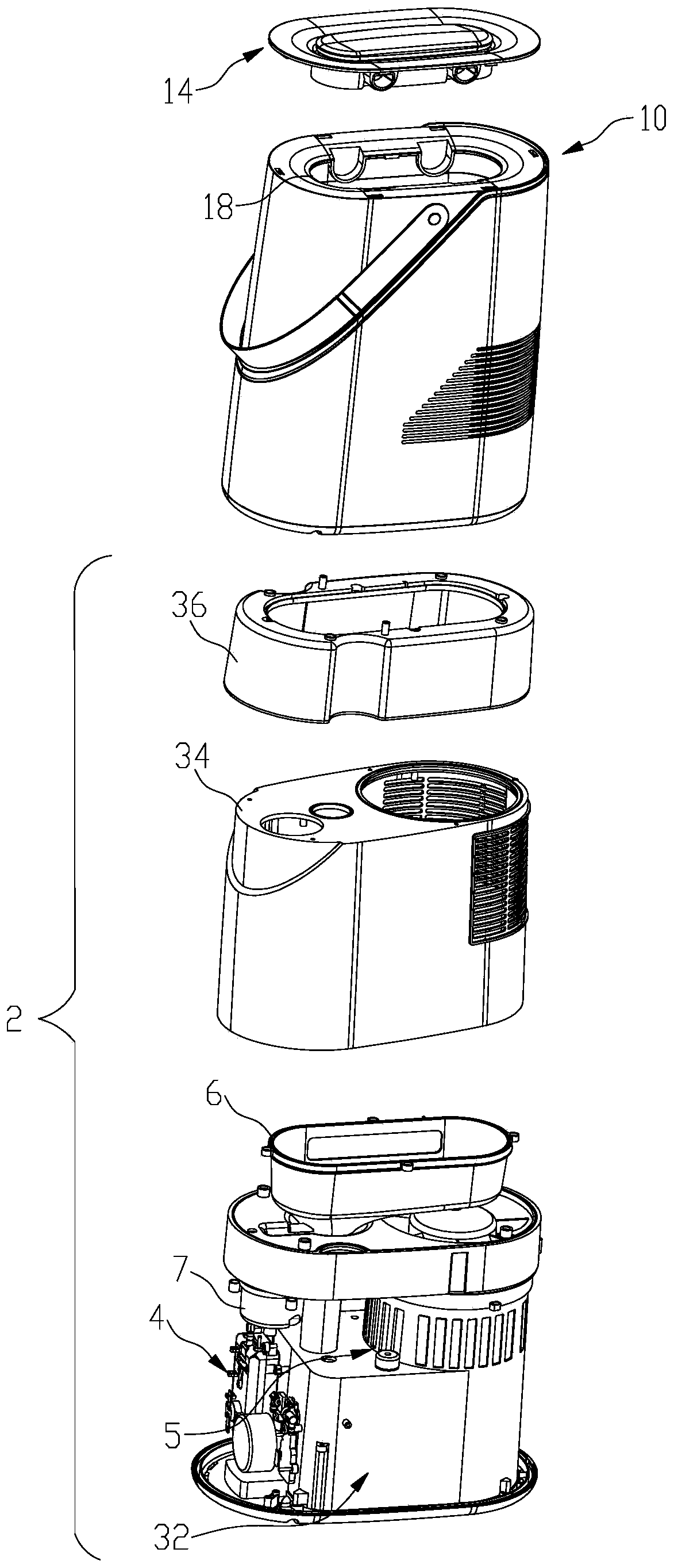

[0034] see Figure 1 to Figure 3 , This is a mixed-energy atomization device according to the embodiment, including a body 2 , a control device (not shown in the figure), a housing 10 and an upper cover 14 .

[0035] The body 2 is provided with a first atomizing mechanism 5 , a second atomizing mechanism 4 and a water adding and exhausting mechanism 6 .

[0036] see Figure 4 to Figure 5 , the first atomization mechanism 5 includes a water storage chamber 32 , a molecular sieve 31 and an atomizing fan 51 , the molecular sieve 31 is installed in the water storage chamber 32 , and the atomizing fan 51 is used to generate an airflow passing through the molecular sieve 31 .

[0037] In order to increase the amount of mist generated by the atomizing fan 51 , the molecular sieve 31 has a hollow columnar structure, and the atomizing fan 51 is arranged at the upper center of the molecular sieve 31 .

[0038] see Figure 4 to Figure 5 , the second atomizing mechanism 4 includes a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com