Launching method of rocket weapon or launcher launching system

A rocket weapon and launch system technology, which is applied in the field of box-type rocket launchers, can solve the problems of long development period, unguaranteed, and short development period of rocket launch vehicles, and achieve shortened development period, guaranteed development progress, and strong environmental adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

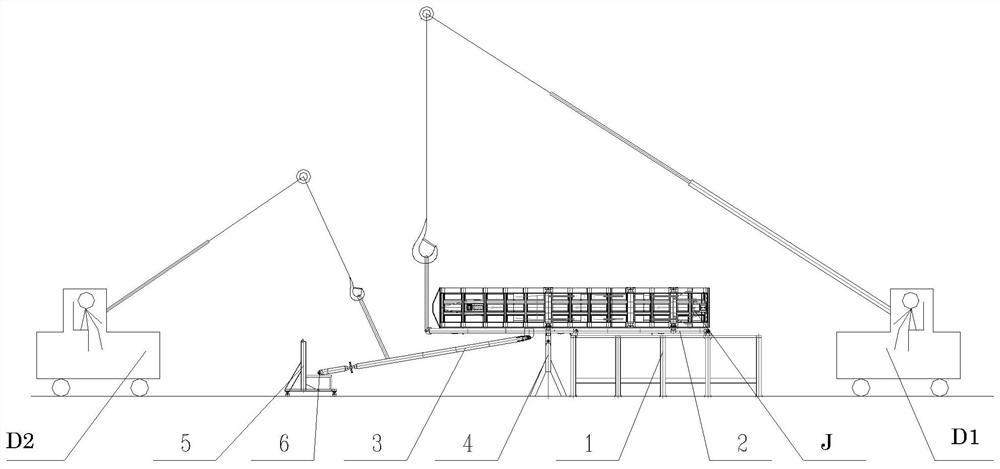

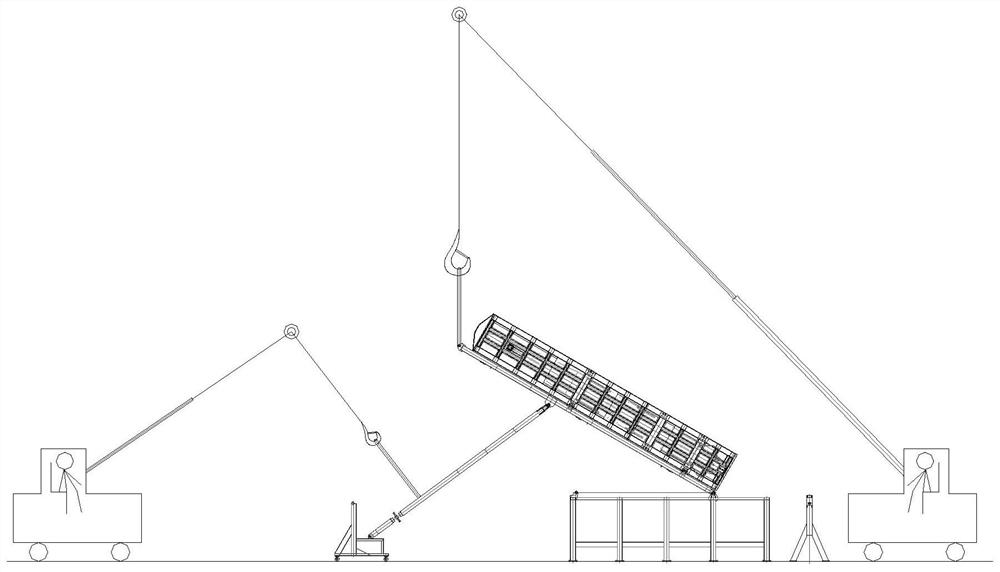

[0053] Such as figure 1 Shown, rocket weapon or launcher launch system, including:

[0054] The base platform 1 is fixed on the ground when in use.

[0055] Erecting platform 2, one end is rotatably fixed on the fixed position of base platform;

[0056] Oblique supporting platform 3, one end is rotatably connected with the erecting platform, and the other end is a free end,

[0057] Wherein, a locking structure is provided at a position away from the fixed position of the base platform,

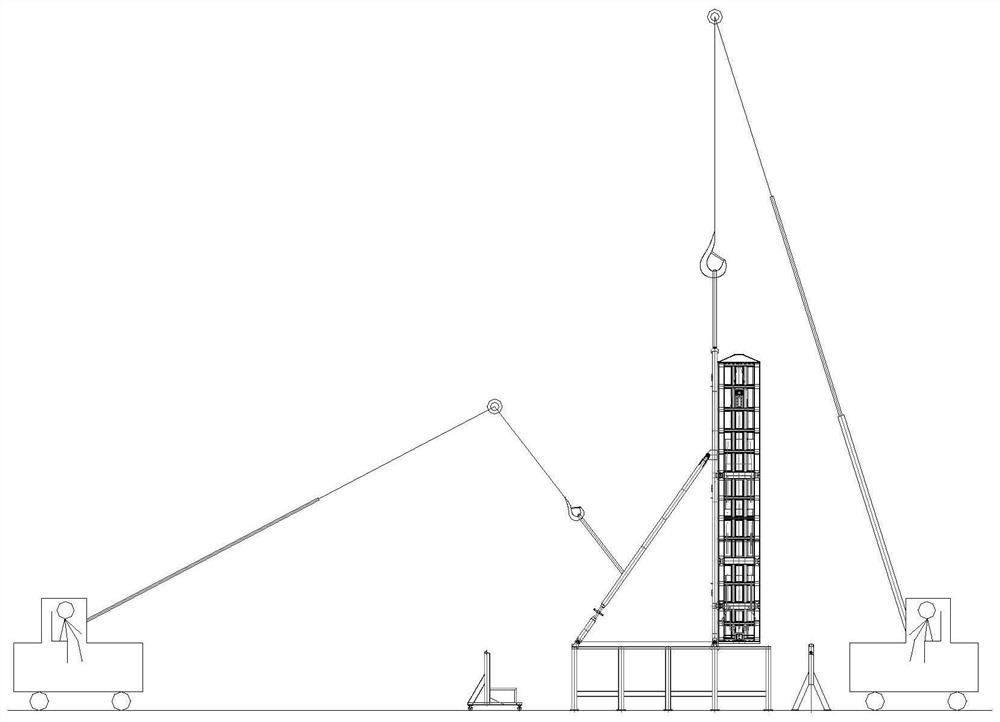

[0058] When the erecting platform is erected and rotated to a predetermined angle, the free end of the inclined support platform is fixed and locked on the base platform through the locking structure arranged on the base platform.

Embodiment 2

[0060] On the basis of Embodiment 1, as an optimization, one end of the erecting platform is fixed on the fixed position of the base platform by a fixed pin; and / or,

[0061] One end of the inclined support platform is rotatably connected with the erecting platform through a pin shaft;

[0062] and / or,

[0063] The locking structure is a pin hole arranged on the base platform,

[0064] When fixing, the fixed pin shaft passes through the pin shaft hole, and the free end of the inclined support platform is connected and fixed at the pin shaft hole through the fixed pin shaft 6 .

[0065] By using the solution of the fixed pin shaft, the structure is simple, the design is convenient for rapid design, and the design and manufacturing time is shortened.

Embodiment 3

[0067] On the basis of the above-mentioned embodiment 1-2, the free end of the oblique support platform is provided with a double-ended screw, and the hole on the oblique support platform can be aligned with the pin shaft hole through the double-ended screw for installation of the fixed pin shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com