Enameled wire paint film tensile test clamp device

A technology of tensile test and fixture device, which can be used in measuring devices, transportation and packaging, electric vehicles, etc. It can solve the problems of enameled wire detachment, damage to enameled wire, and inaccurate test data, etc., and achieve increased friction and stable clamping force , to ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0047] The present invention also has the following embodiments on the basis of the above:

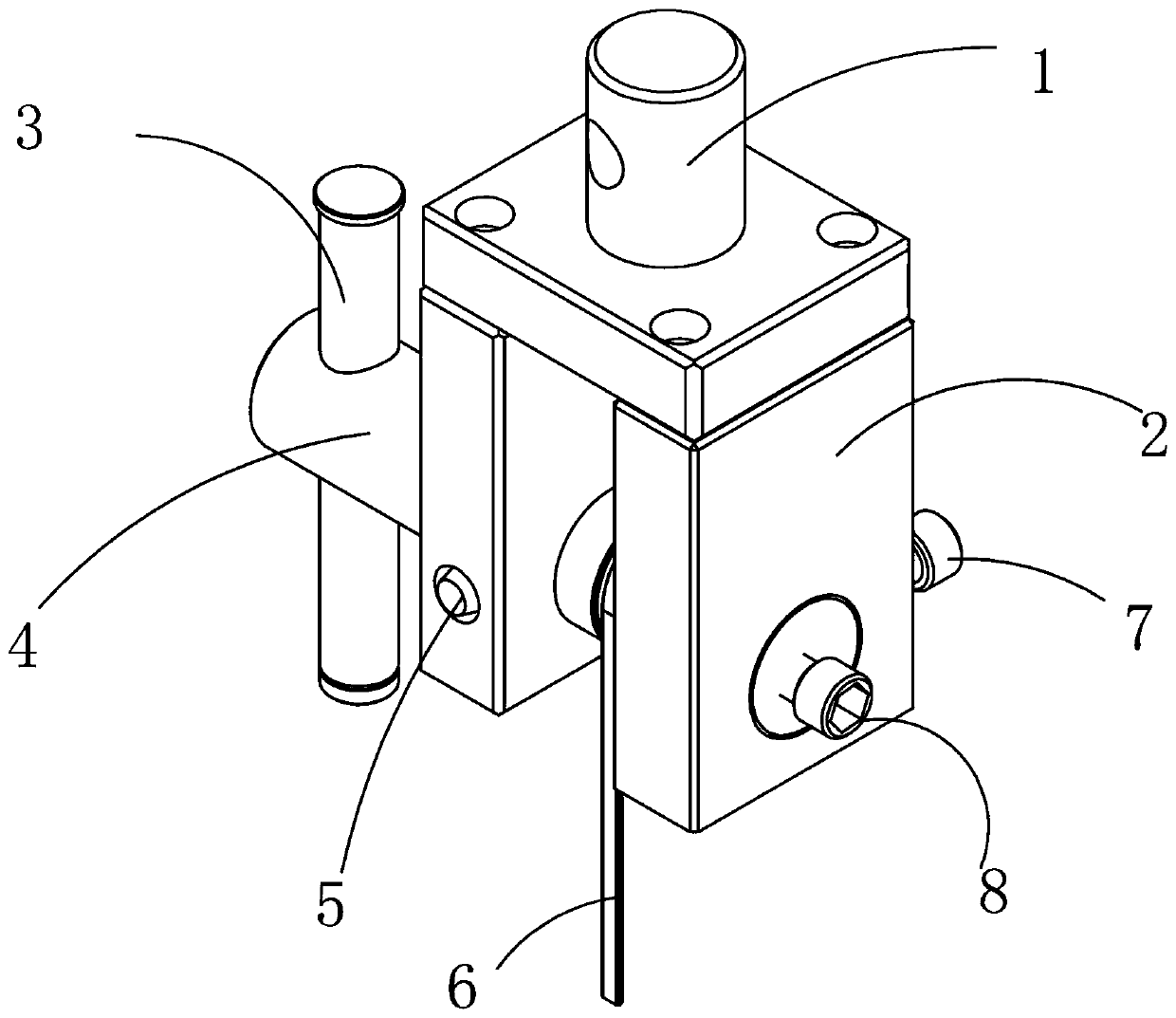

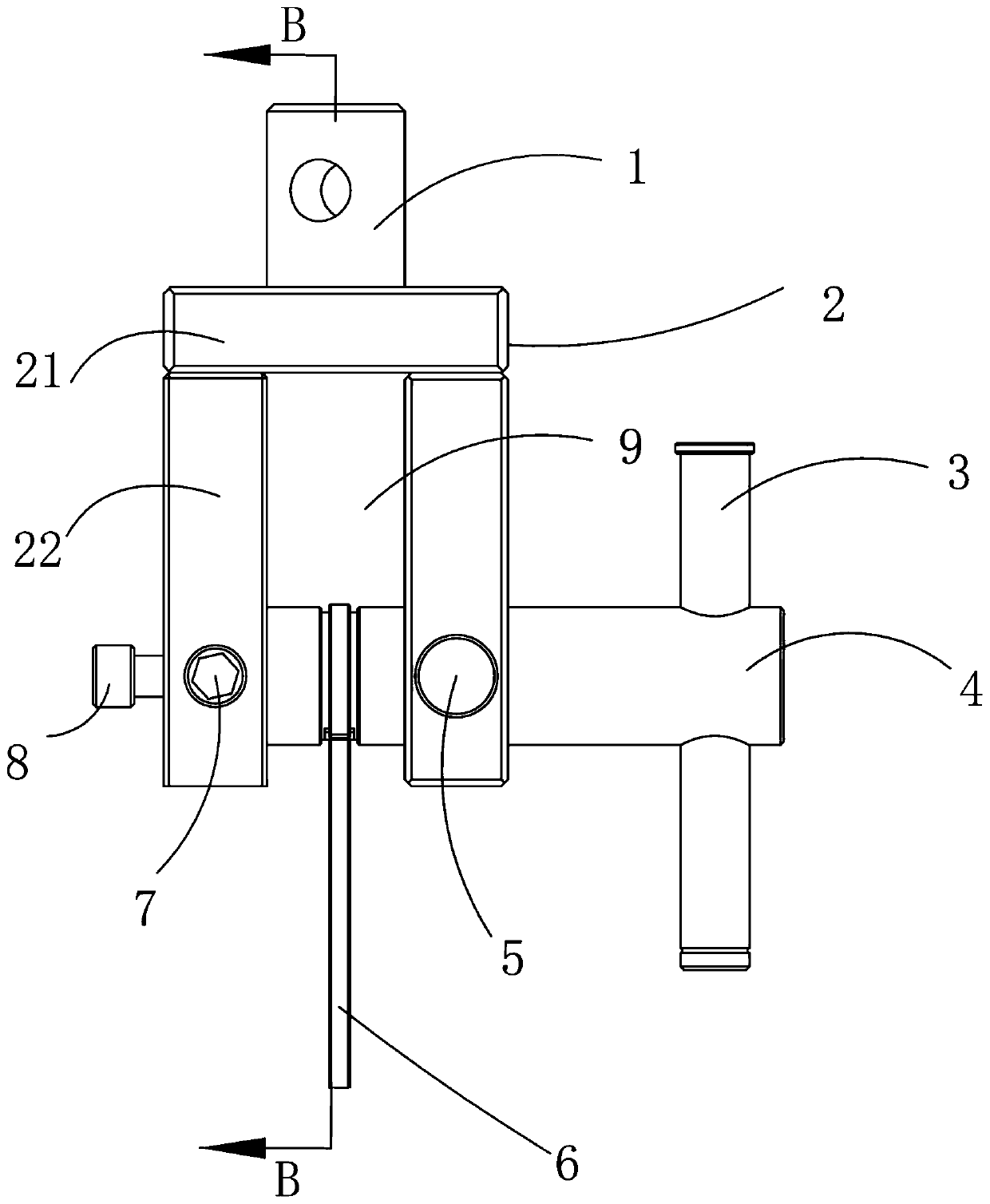

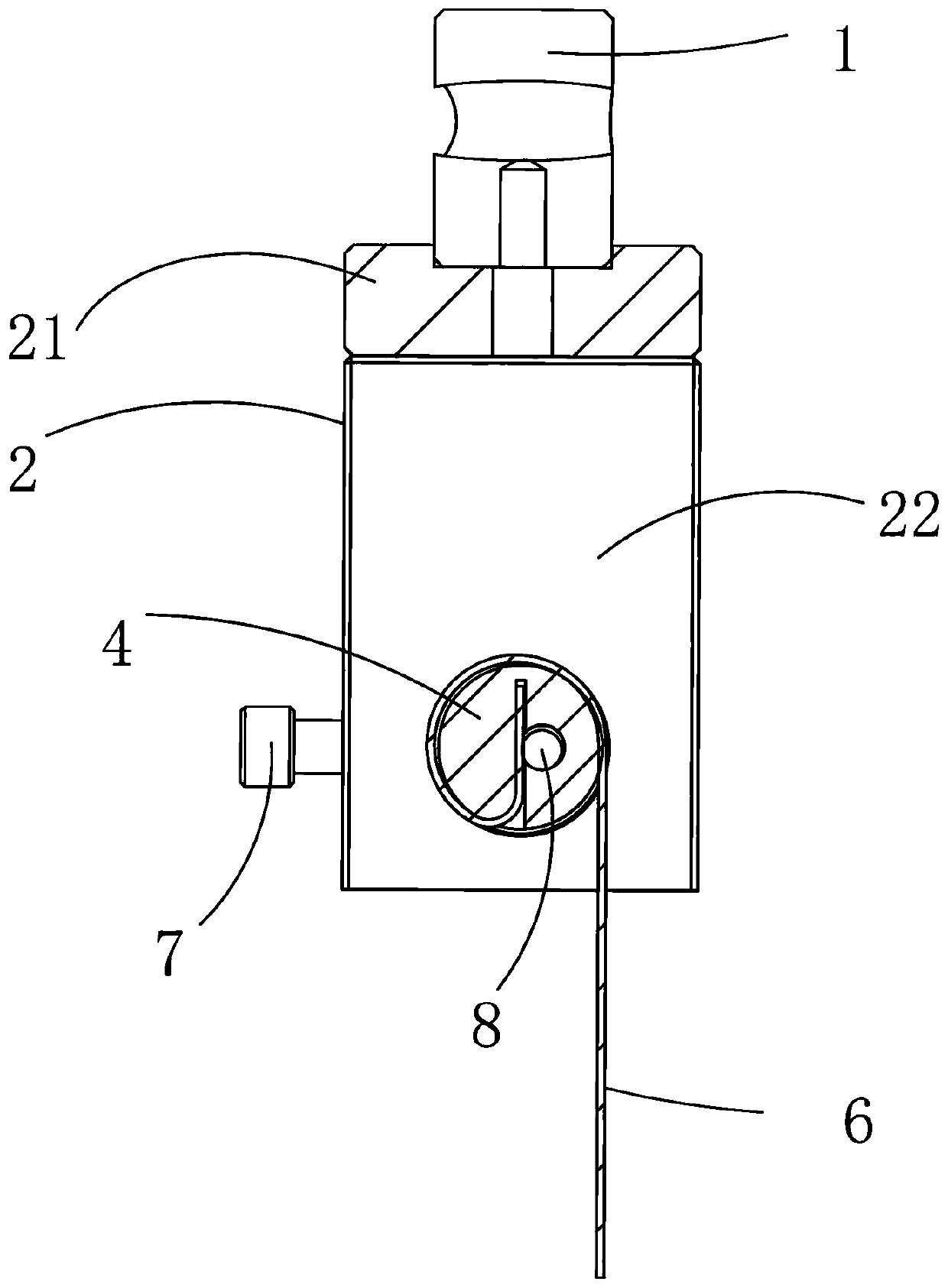

[0048] In further embodiments of the present invention, please continue to refer to Figure 1 to Figure 10 As shown, the end of one end of the rotating shaft 4 is provided with an eccentric hole 41. The central axis of the eccentric hole 41 and the central axis of the rotating shaft 4 are parallel to each other and do not coincide with each other. The eccentric hole 41 includes a threaded hole and an optical hole that communicate with each other. A shaft 81 is threadedly connected with the threaded hole, and the second shaft 82 extends into the light hole.

[0049] In a further embodiment of the present invention, the peripheral wall of one end of the rotating shaft 4 is provided with a positioning groove 42 , the positioning groove 42 is located in the other side plate 22 , and the positioning pin 7 passes through the other side plate 22 and extends into the positioning groove 42, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com