A multi-convex type water-permeable layer and its manufacturing method

A manufacturing method and technology for a water-permeable layer, which are applied in the fields of medical science, absorbent pads, bandages, etc., can solve the problems of increasing liquid leakage and affecting the user's comfort, so as to improve comfort, facilitate liquid diversion, and improve fluid transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

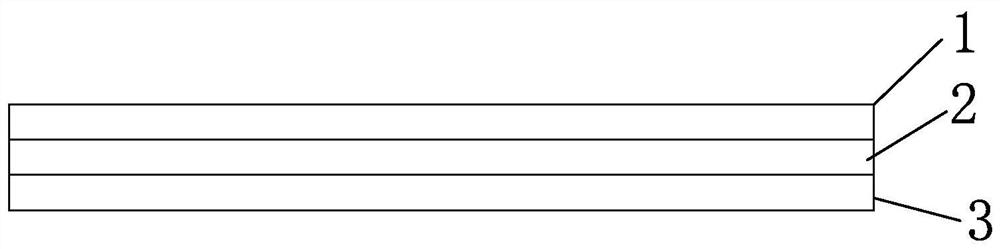

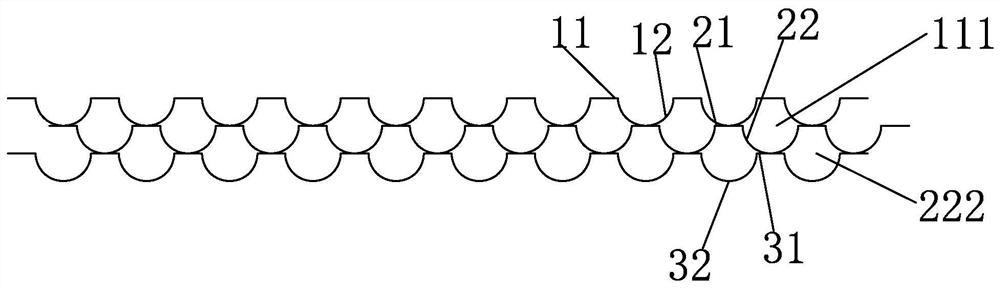

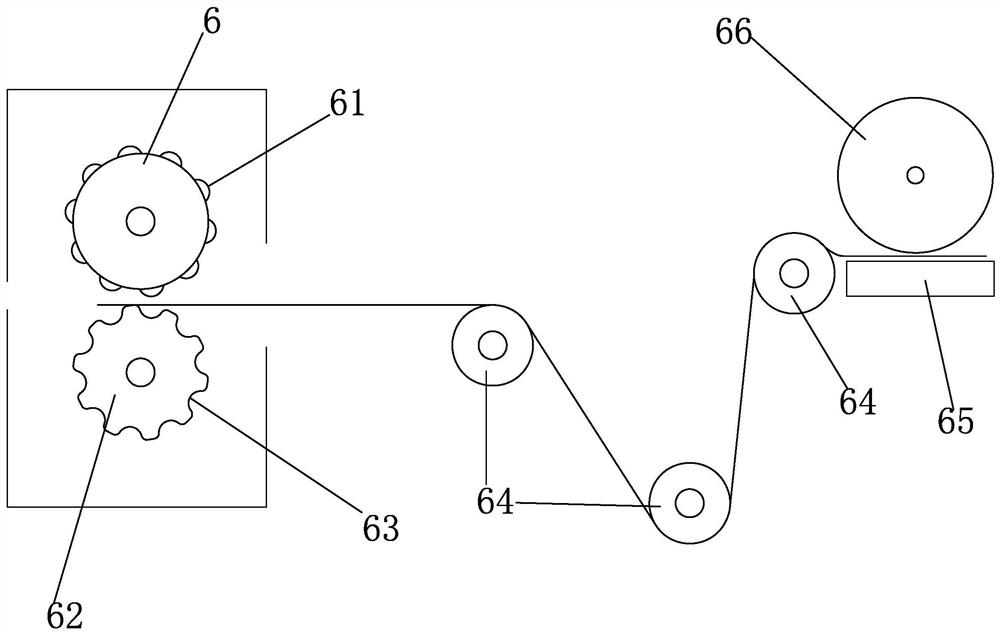

[0029] refer to Figure 1 to Figure 7 , a multi-convex type water-permeable layer, including a surface layer 1, a middle layer 2, and a bottom layer 3, and the surface layer 1, the middle layer 2, and the bottom layer 3 are all made of non-woven fabrics. The surface layer 1 includes a first plane 11, and first arcuate surfaces 12 arranged at intervals in the first plane 11, and the intermediate layer 2 includes a second plane 21, and second arcuate surfaces arranged at intervals in the second plane 21. 22. The bottom layer 3 includes a third plane 31 and a third arcuate surface 32 arranged at intervals in the third plane 31. The first arcuate surface 12 and the second plane 21 conflict with each other, and the second arcuate surface 22 and the The third planes 31 conflict with each other. By laminating multiple layers, the first arc surface 12, the second arc surface 22, and the third arc surface 32 can guide the flow, and the first arc surface 12, the second arc surface 22, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com