A method for adjusting the amount of misalignment of rollers during misalignment spinning of cylindrical parts

A technology of staggered pitch spinning and adjustment method, which is applied in the field of manufacturing thin-walled rotary metal components, which can solve the problems of poor overall accuracy of the workpiece, unstable deformation during spinning, and shortened effective length of the workpiece, and achieve straightness Improve and improve the forming accuracy and forming quality, and avoid the effect of distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In this embodiment, a high-strength steel thin-walled cylindrical piece is processed by the two-roller staggered-pitch spinning method. According to the definition of the ULSAB project team of the World Iron and Steel Association, steel with a yield strength of 210-550Mpa is defined as high-strength steel.

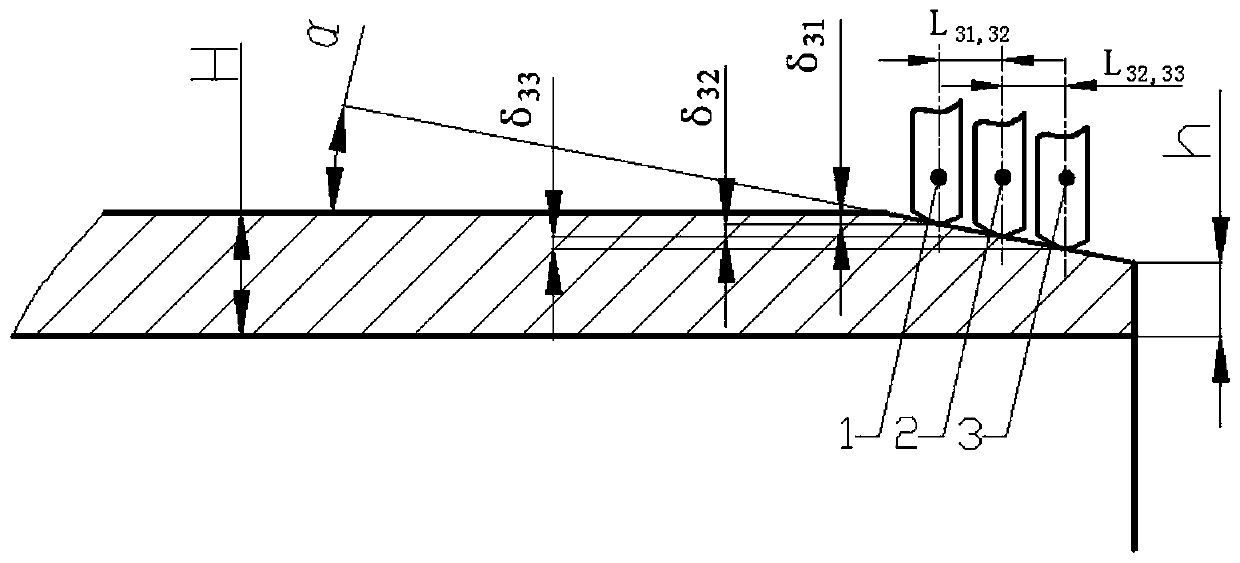

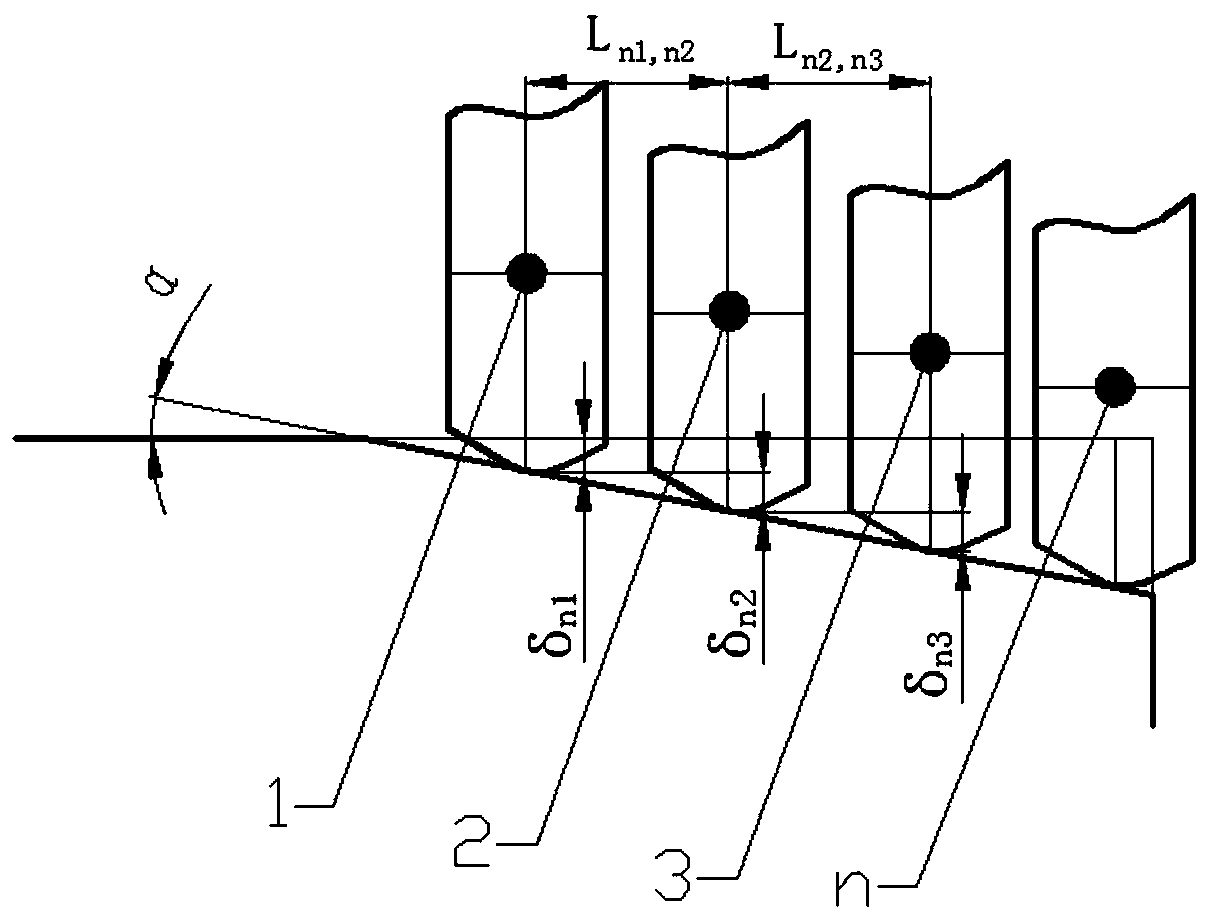

[0044] The axial offset refers to the distance between the apexes of the rounded corners of axially adjacent rollers when two or more rollers are used for spinning.

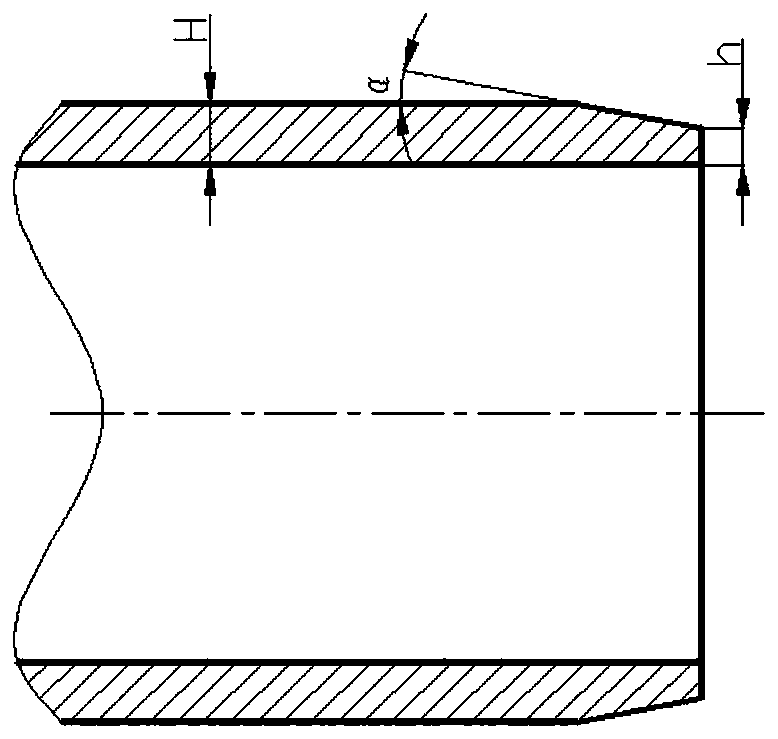

[0045] The structure of the workpiece processed in this embodiment is as Figure 4 shown. The concrete process of this embodiment is:

[0046] The first step is to prepare spinning blanks. The blank is a 30CrMnSiA high-strength steel cylinder. The thickness of the spinning blank is H, h is the thickness of the blank at the spinning end, the height of the outer round chamfer of the cross section of the spinning end is H-h, and the angle between the chamfering slope and the horizontal plane is α.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com