Distribution box preset hole breaking device

A technology of presetting holes and distribution boxes, which is applied in the field of transformation and distribution network, can solve problems such as danger, achieve high installation efficiency and achieve the effect of angle adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

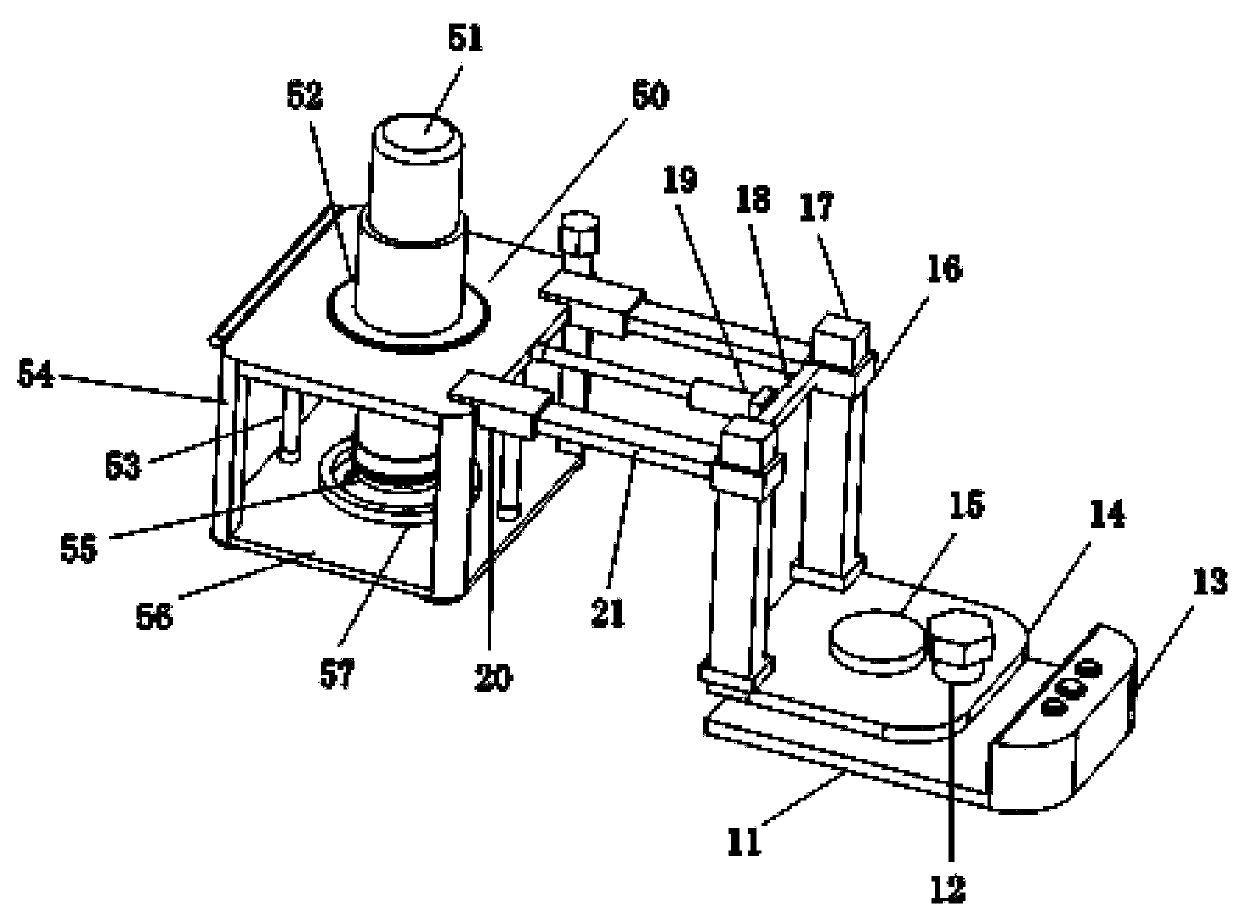

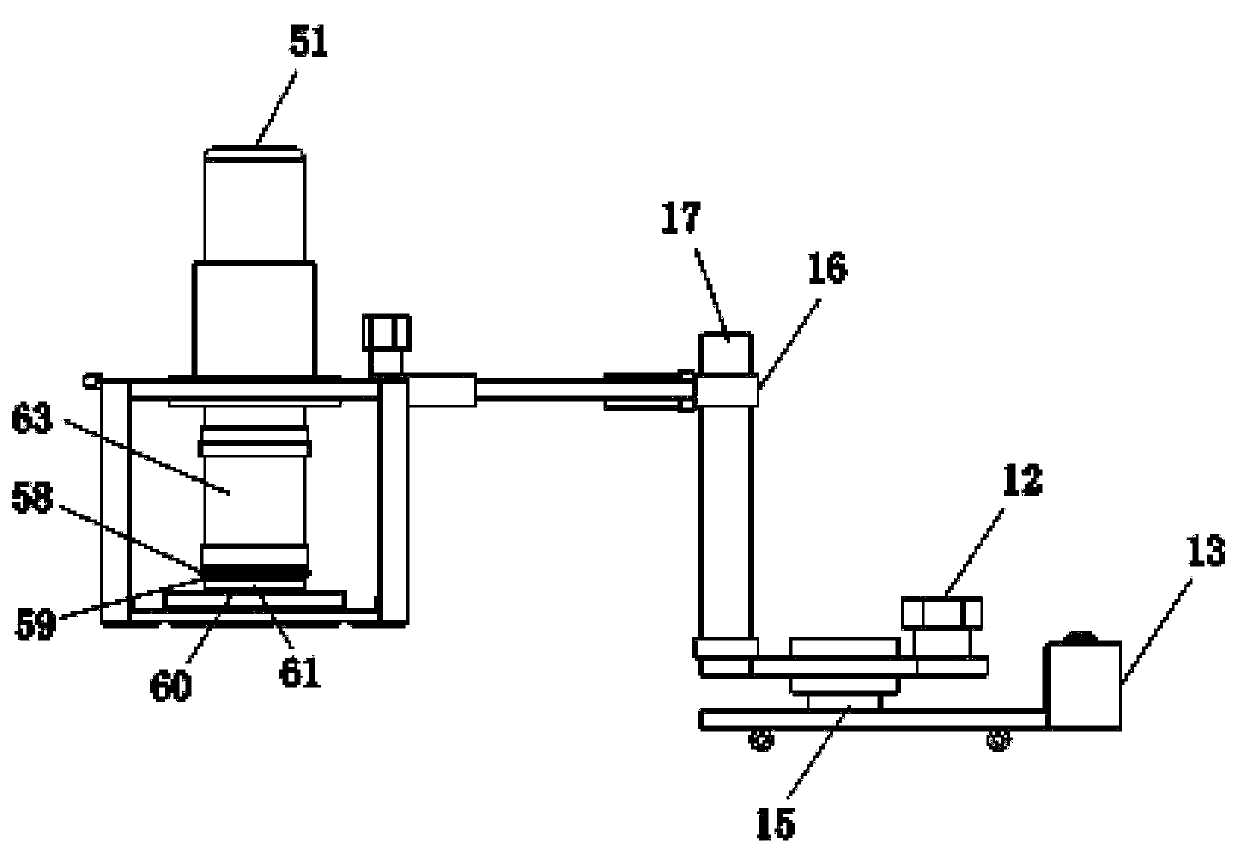

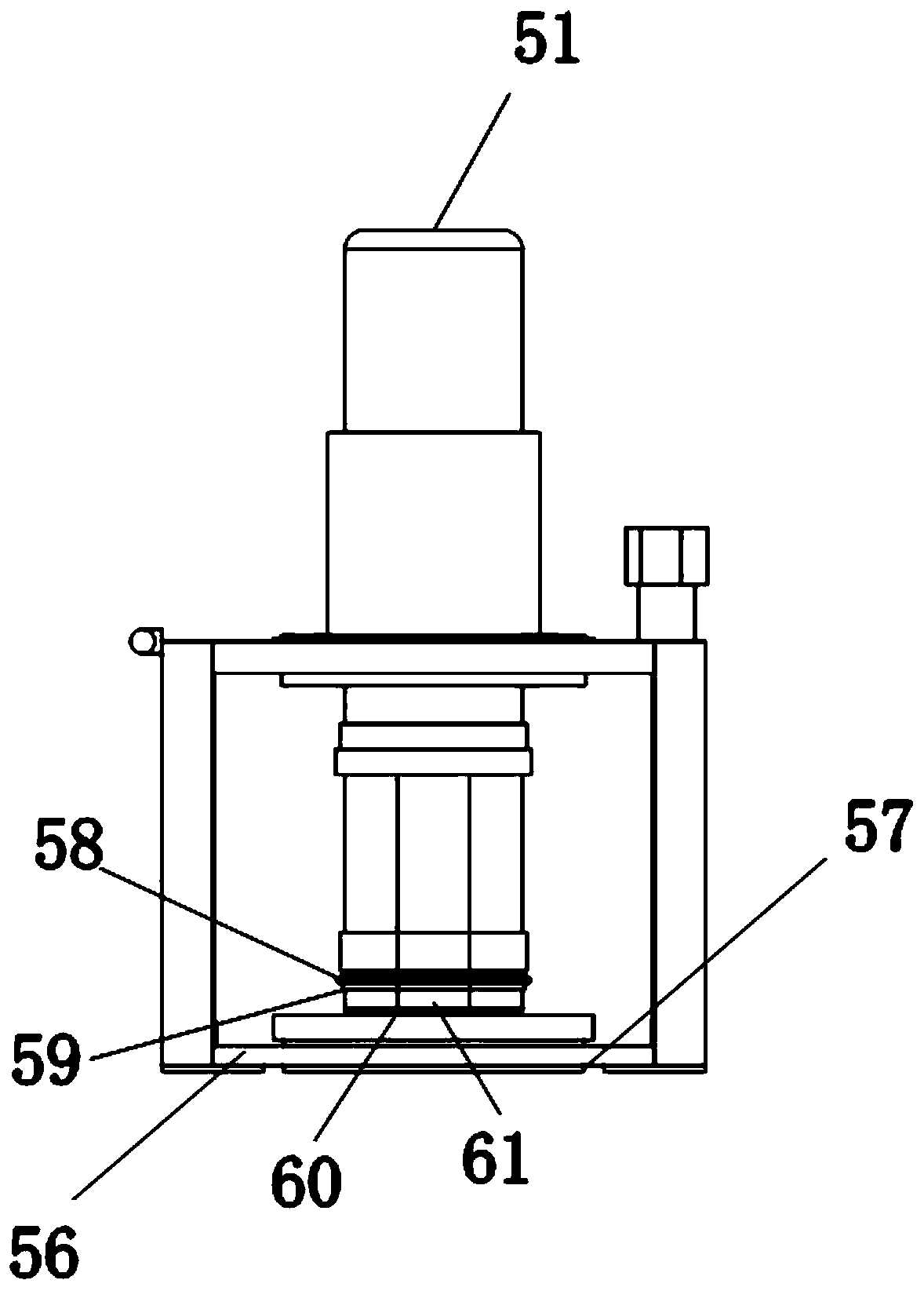

[0038] like Figure 1 to Figure 5 As shown, the embodiment of the present invention provides a device for breaking a preset hole in a distribution box, including an auxiliary adjustment component and a breaking component, and the preset hole is broken through the auxiliary adjustment component and the breaking component.

[0039] Specifically, the auxiliary adjustment assembly includes a main base 11, an intermediate turntable 14 arranged on the main base 11 and rotatably connected to it, a vertical guide rod 17 fixedly connected to the middle turntable 14, and a sliding connection set on the The vertical sliding sleeve 16 on the vertical guide rod 17, the horizontal sliding rod 21 fixedly connected to the vertical sliding sleeve 16, and the sliding connection sleeve are arranged on the side of the horizontal sliding rod 21 away from the vertical sliding sleeve 16. The horizontal sliding sleeve 20 on one end and the horizontal adjustment push mechanism 19; the breaking assembl...

Embodiment 2

[0042] On the basis of Embodiment 1, moving wheels are provided under the main base 11 to facilitate the movement of the entire breaking device.

Embodiment 3

[0044] On the basis of Embodiment 1, the auxiliary adjustment assembly also includes an adjustment shaft 15, and a rotation shaft hole is provided on the intermediate turntable 14, and the main base 11 and the intermediate rotation shaft pass through the adjustment shaft 15 and the rotation shaft hole. The fit and rotation connection between them. An adjustment knob 12 is provided on one side of the middle turntable 14 , and the adjustment knob 12 is set on the middle turntable 14 for adjusting the rotation between the middle turntable 14 and the main base 11 . This embodiment discloses a specific rotational connection mode between the intermediate turntable 14 and the main base 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com