Automatic milling machine

A feeder, automatic technology, applied in the field of notebook computer manufacturing, can solve the problem of unbalanced force on the shell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

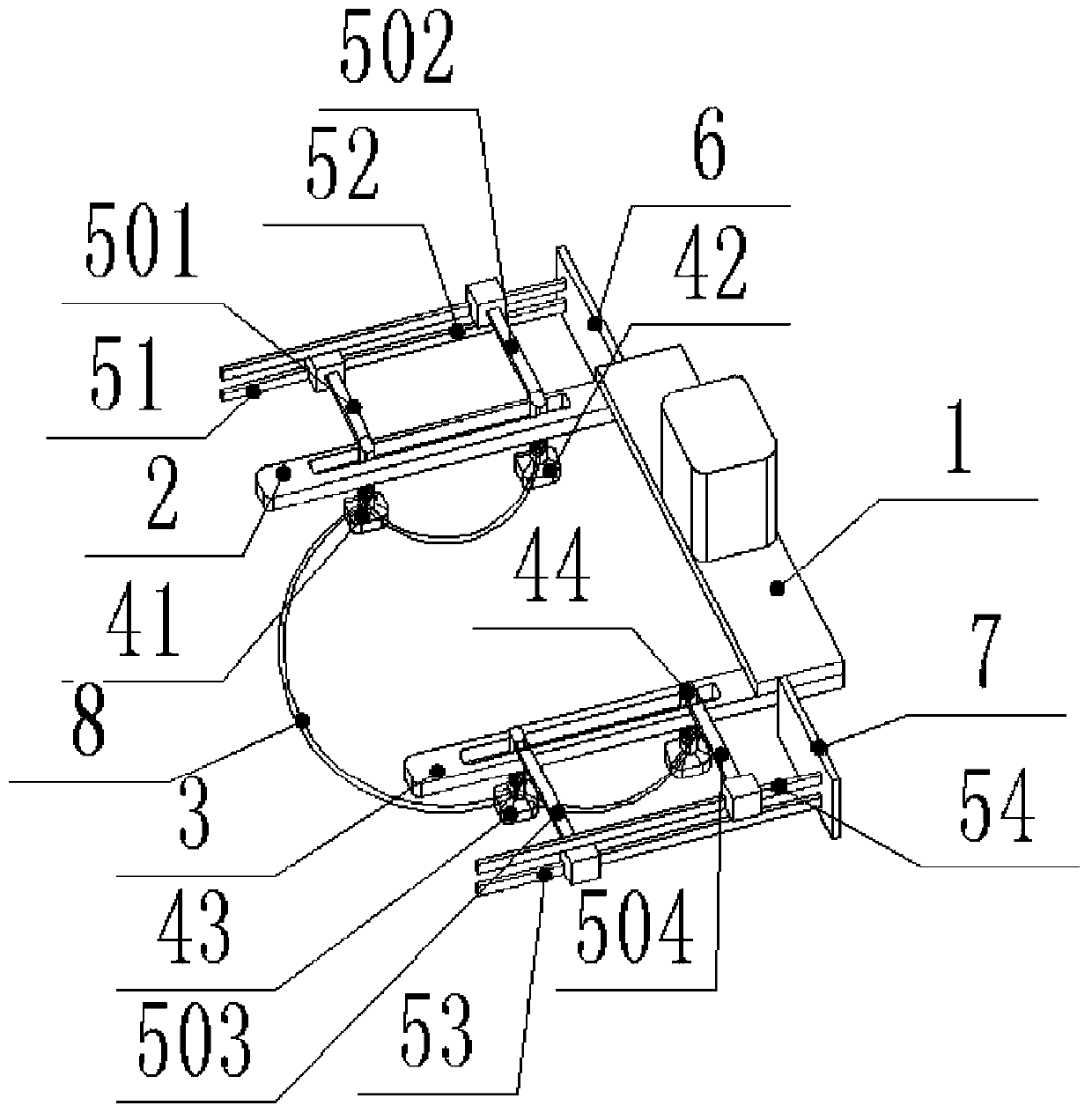

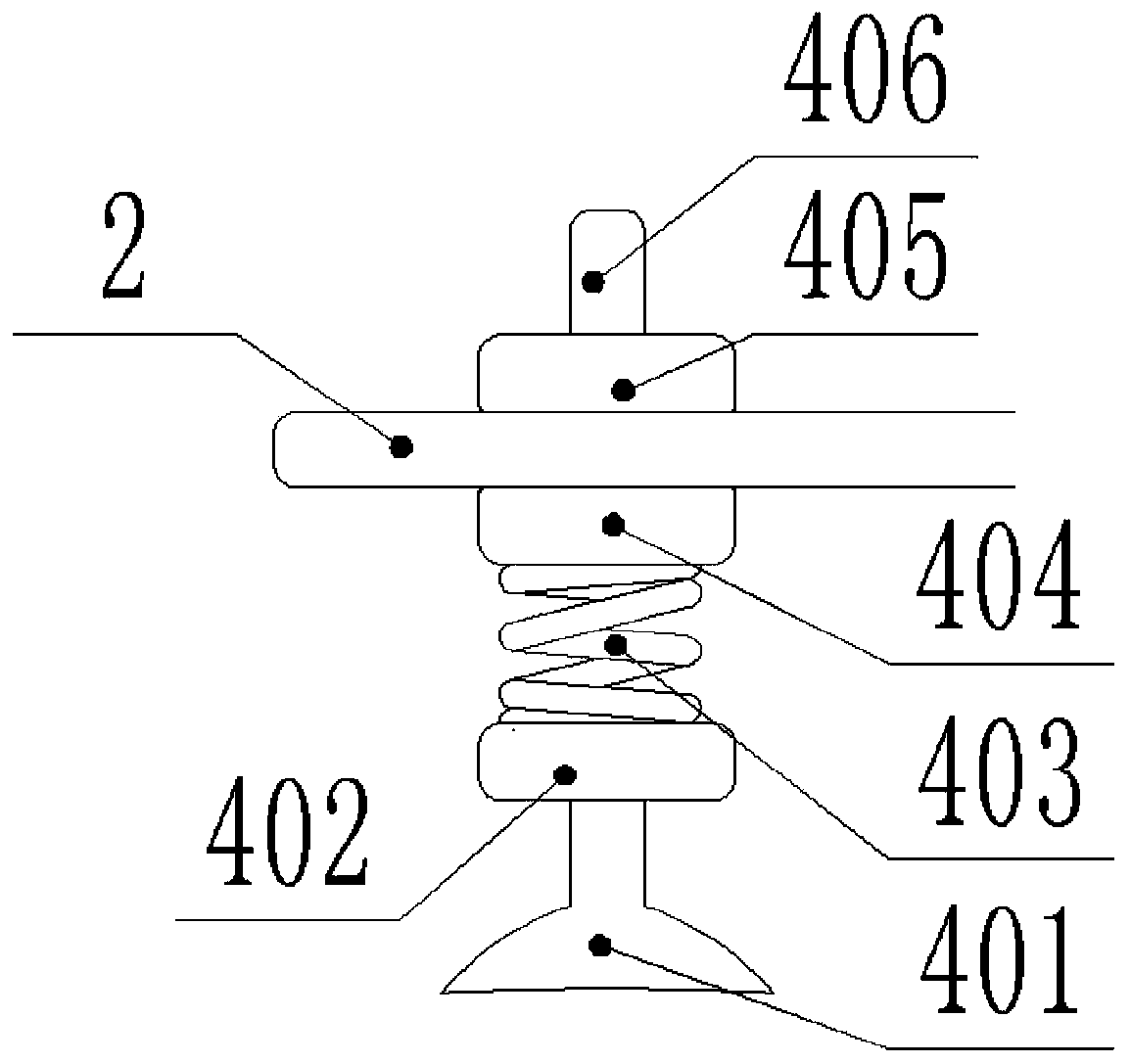

[0021] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0022] The reference signs in the drawings of the description include:

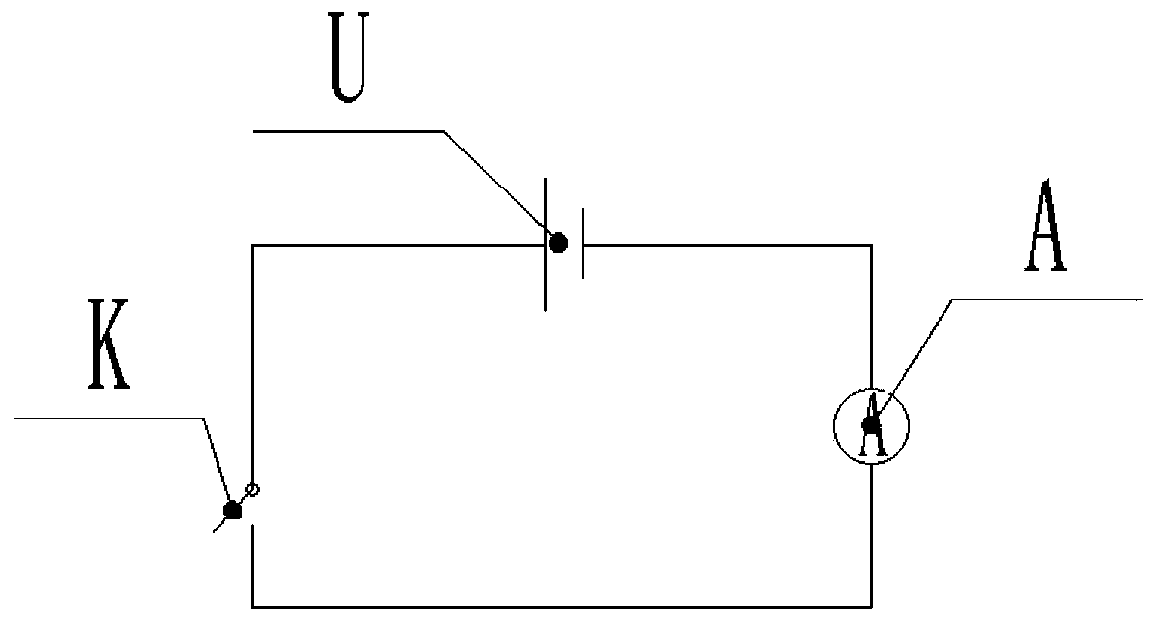

[0023] Fixed plate 1, first suction cup mounting plate 2, second suction cup mounting plate 3, suction nozzle 401, first connecting block 402, elastic element 403, second connecting block 404, third connecting block 405, connecting column 406, first Suction cup 41, the second suction cup 42, the 3rd suction cup 43, the 4th suction cup 44, the first linear motor 51, the first connecting rod 501, the second linear motor 52, the second connecting rod 502, the 3rd linear motor 53, the 3rd linear motor Three connecting rods 503, the fourth linear motor 54, the fourth connecting rod 504, the first motor mounting plate 6, the second motor mounting plate 7, the gas pipe 8, the first parallel plate B1, the second parallel plate B2, the insulating spring B3, Power supply U, swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com