A method for determining the position of a composite material surface layered laser projector

A technology of laser projectors and composite materials, which is applied to household appliances, other household appliances, household components, etc., to achieve the effect of improving structural consistency and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0109] Example 1 For the projection line, its location point coordinates and normal vectors are shown in Table 1.

[0110] Table 1 Projection location points and normal vectors

[0111]

[0112]

[0113]

[0114]

[0115]

[0116]

[0117]

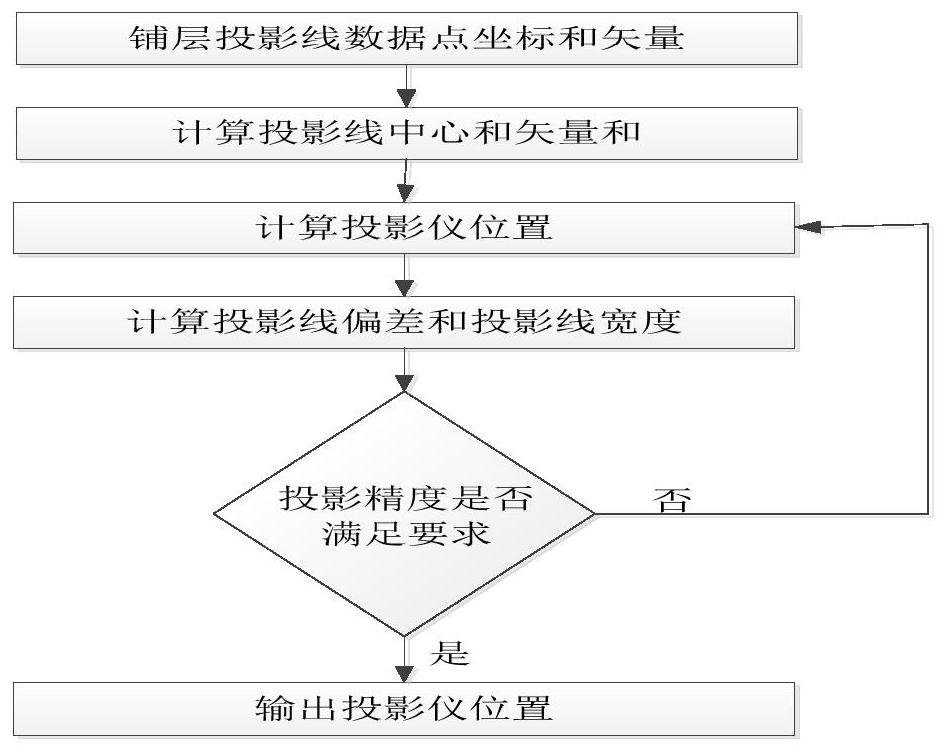

[0118] Step 1, select the position coordinates and the normal vector of the projection point of the composite material layup, and calculate the center point P1 and the direction vector and R of the projection point;

[0119] The coordinates and vector sum R of the center point P1 of the projection line are

[0120]

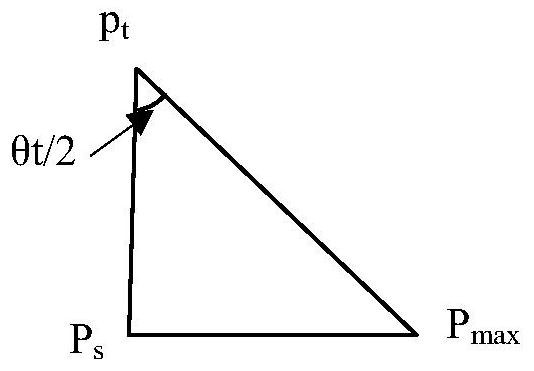

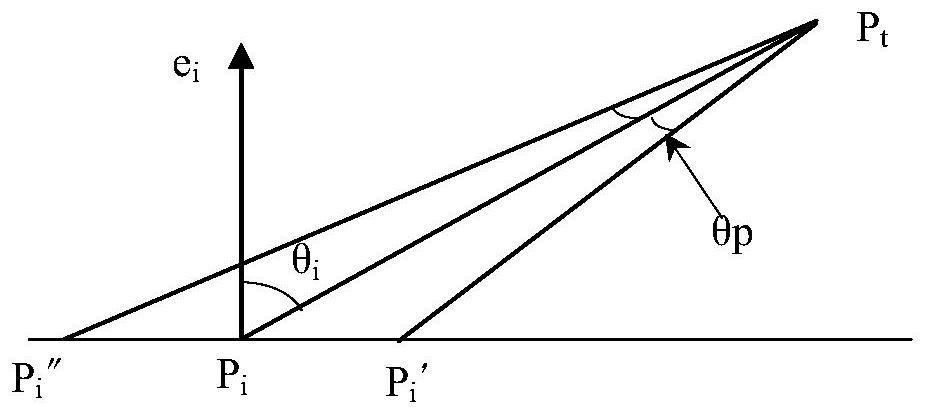

[0121] Step 2, establish a straight line equation M1 passing through the center point P1 along the vector and R direction, starting from the center point, along the vector and direction, establish a point P2 at a certain distance from the starting point; for each projection point, establish a projection point and P 2 The equation of the straight line m 2 , to calculate the straight line m 2 and M 1...

example 2

[0152] Step 1, select the position coordinates and the normal vector of the projection point of the composite material layup, and calculate the center point P1 and the direction vector and R of the projection point;

[0153] The coordinates and vector sum R of the center point P1 of the projection line are and (e i , e y , ez )

[0154] Step 2, establish a straight line equation M1 passing through the center point P1 along the vector and R direction, starting from the center point, along the vector and direction, establish a point P2 at a certain distance from the starting point; for each projection point, establish a projected point and the linear equation m2 of P2, calculate the angle θ between the straight line m2 and M1, and find the coordinates (xi, yi, zi) of the projection point Oi with the maximum angle; calculate the distance L between the projection point of the maximum angle and the line M1;

[0155] The equation of the straight line M1 passing through the cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com