Flat plate base type accelerated discharge device and steel plate bin thereof

A discharge device and steel silo technology, which is applied in the field of steel silos, can solve problems such as loss of boosting ability, excess powder materials, and easy wet agglomeration, etc., to achieve the effect of improving the boosting force and ensuring the boosting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the content of the present invention, the present invention will be described in detail below in conjunction with specific examples.

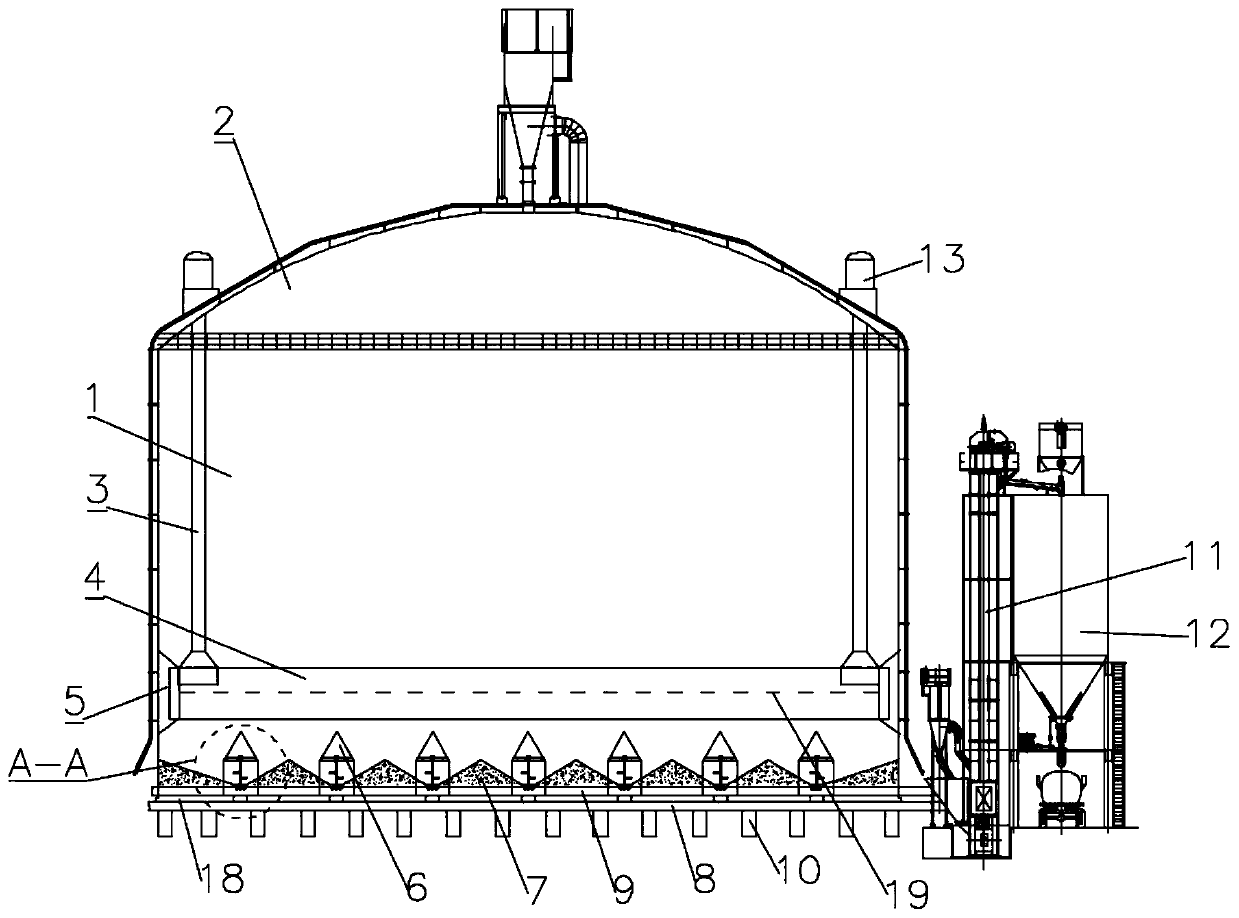

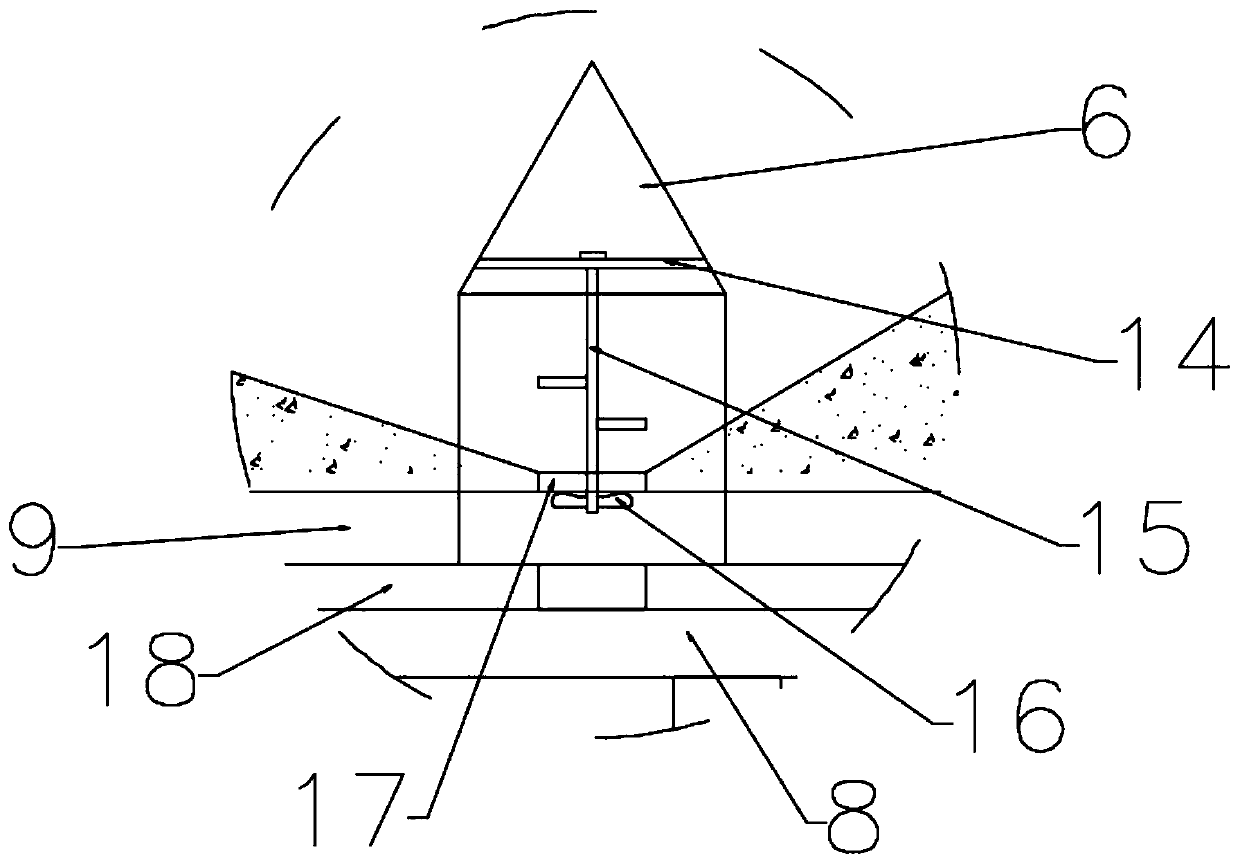

[0026] Such as Figure 1-2 As shown, according to an embodiment of the flat-plate foundation type accelerated discharge device and its steel silo provided by the present invention, it includes a silo body 1 and a silo roof 2 in a cylindrical structure, and the silo roof 2 is arranged on the top of the silo body 1, It also includes an agglomeration crushing assembly, the bottom of the bin body 1 is fixed with a flat bin bottom 18, and a plurality of equally spaced discharge pipes 9 are arranged on the flat bin bottom 18, and the top of the discharge pipe 9 is provided with A plurality of equally spaced feeding holes 17 communicated with the inside, and a plurality of equidistantly distributed feed cones 7 are installed on the flat silo bottom 18, and on the flat silo bottom 18 between adjacent said feed cone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com