A direct-injection multi-stage power underwater high-speed thruster and its control method

A powered water, direct-injection technology, used in jet propulsion devices, ramjet engines, and engines that use a combination of propulsion devices, etc., can solve the problems of lack of flexibility, difficulty in achieving speed conversion, and single speed, and improve combat The effect of performance, reasonable layout of structure space, and guarantee of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

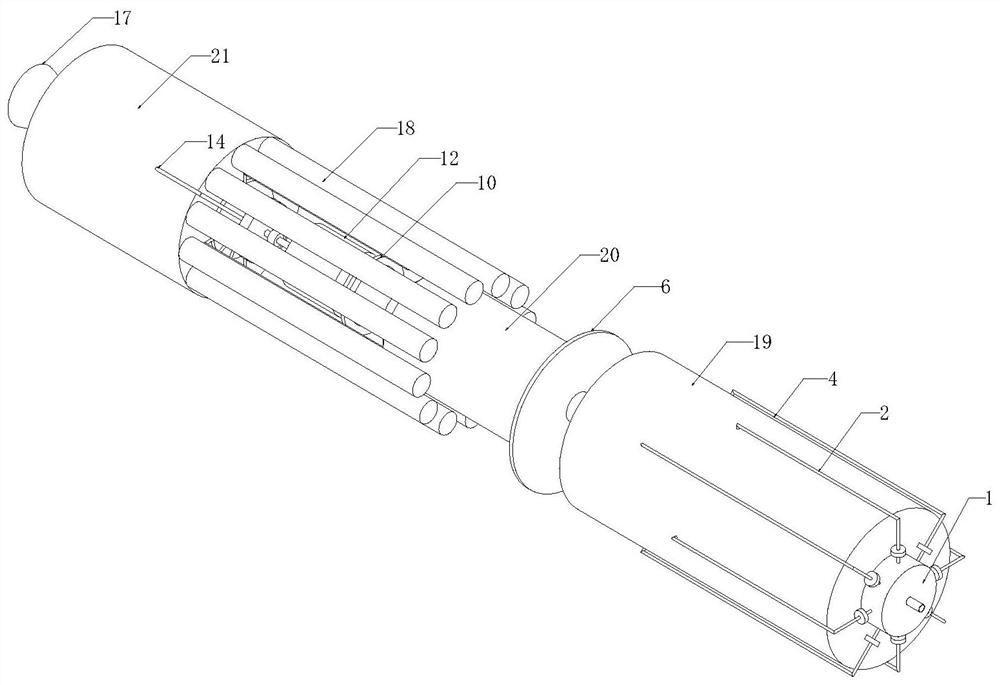

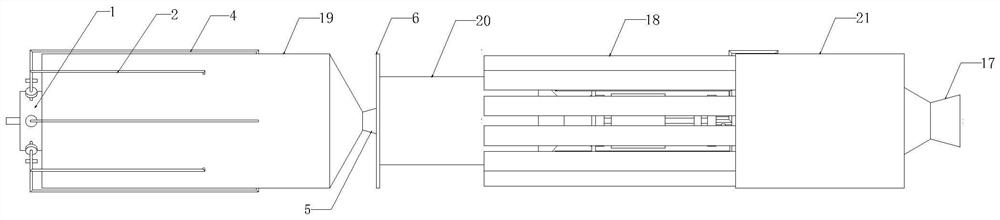

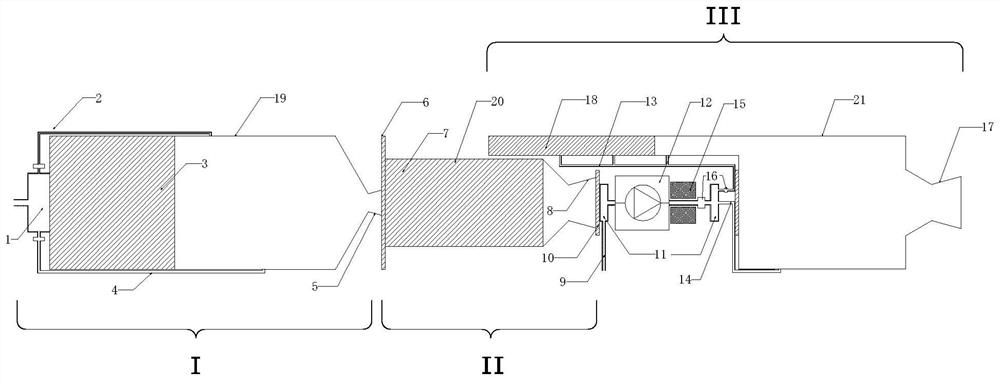

[0038] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0039] Such as Figure 1-6 As shown, the direct-injection multi-stage power underwater high-speed thruster of the present invention mainly includes a high-speed section engine I, an acceleration section engine II and a low-speed section engine III, and the three parts are connected in sequence, and the acceleration section part is half-coated inside the low-speed engine , and the three parts are respectively fixedly connected with the aircraft shell by bolts. In the present invention, the advancing direction of the propeller is the front, and the reverse direction is the rear.

[0040] The high-speed section engine 1 mainly includes the high-speed section water inlet buffer chamber 1, the high-speed section primary water injection pipeline 2, the water stamping metal fuel 3, the high-speed section secondary water injection pipeline 4, the high-speed secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com