A Bending Test Method for F-Type Socket Joint of Rectangular Pipe Jacking Tunnel

A technology of rectangular pipe jacking and socket joints, applied in the direction of applying stable bending force to test material strength, elasticity, machine/structural components, etc., to achieve the effect of clear mechanical concept and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

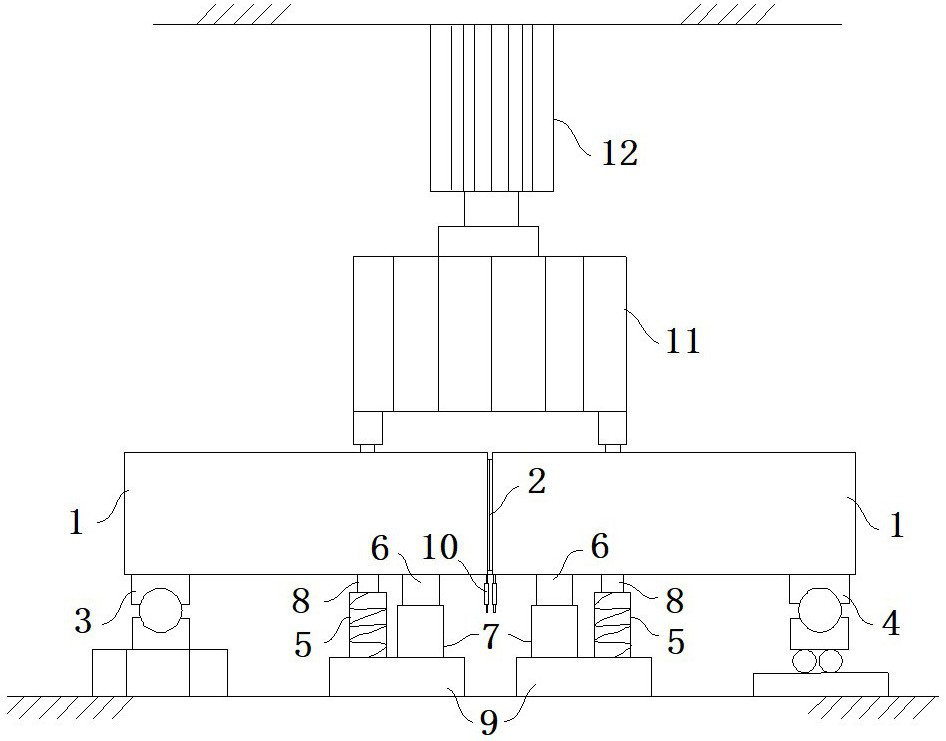

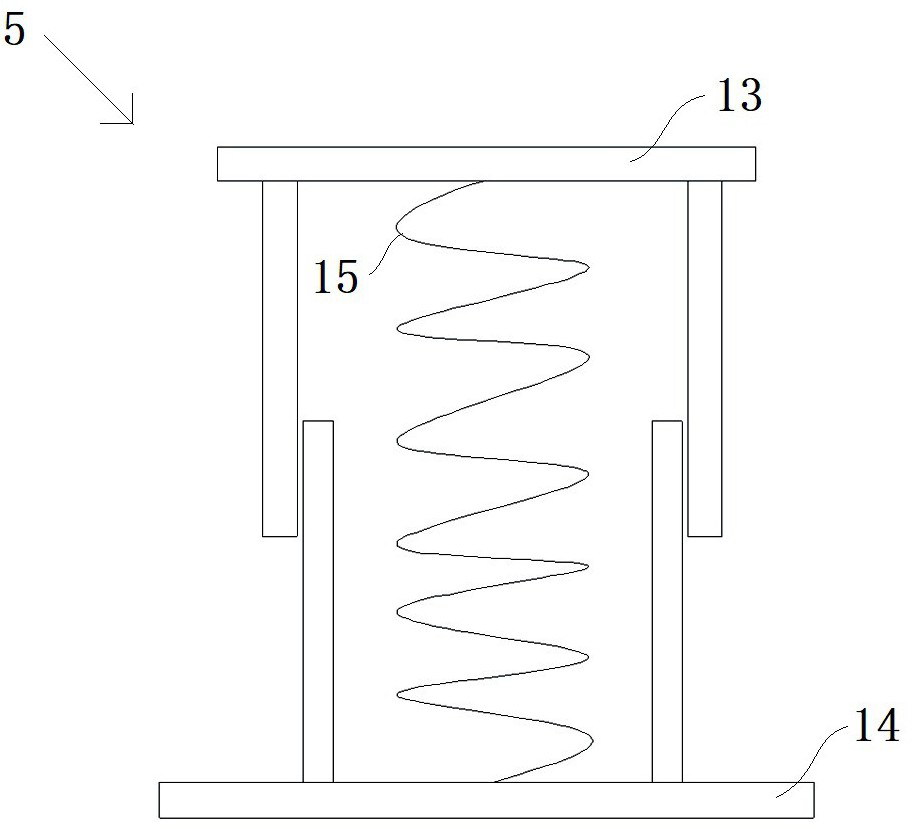

[0023] Example: such as Figure 1-5 As shown, this embodiment specifically relates to a bending test method for F-type socket joints of rectangular pipe-jacking tunnels. A joint is formed at the joint, and a support system is set under the two rectangular pipe jacking members 1, and loads of various levels are applied to the rectangular pipe jacking members 1 on both sides of the joint through the actuator 12 to simulate the bending mechanical behavior of the joint to obtain test data. It is analyzed and processed to obtain the rotational stiffness model of the rectangular pipe jacking joint.

[0024] Such as Figure 1-5 As shown, the specific steps of the bending test method of the F-type socket joint of the rectangular pipe jacking tunnel in this embodiment are as follows:

[0025] (1) if figure 1 As shown, the two rectangular pipe jacking components 1 are connected into one body by using the F-type socket method, and an F-type socket joint is formed at the joint of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com