A method for burn-in testing of surface-mounted FETs

A test method and field effect technology, which is applied in the field of component reliability screening and testing, can solve problems such as difficulty in testing, affecting component reliability, and high rated power, so as to achieve independent temperature control and facilitate burn-in The effect of the experiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

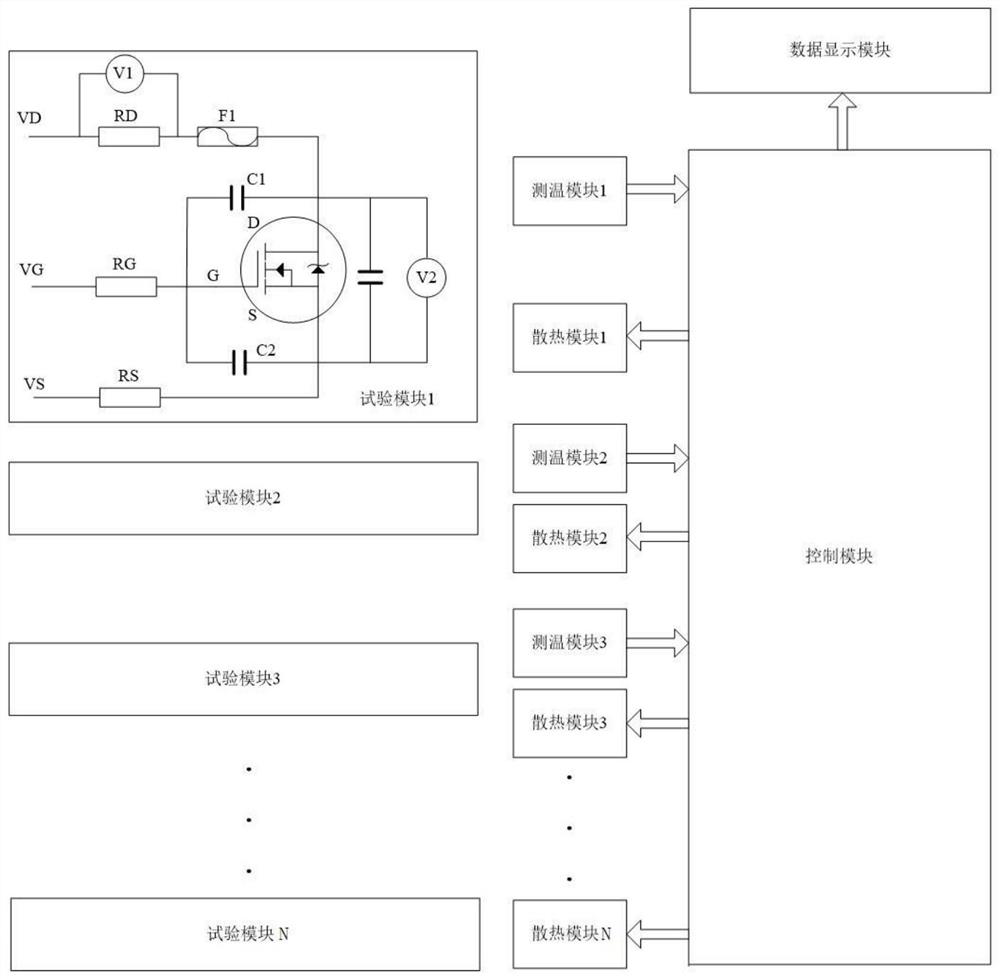

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

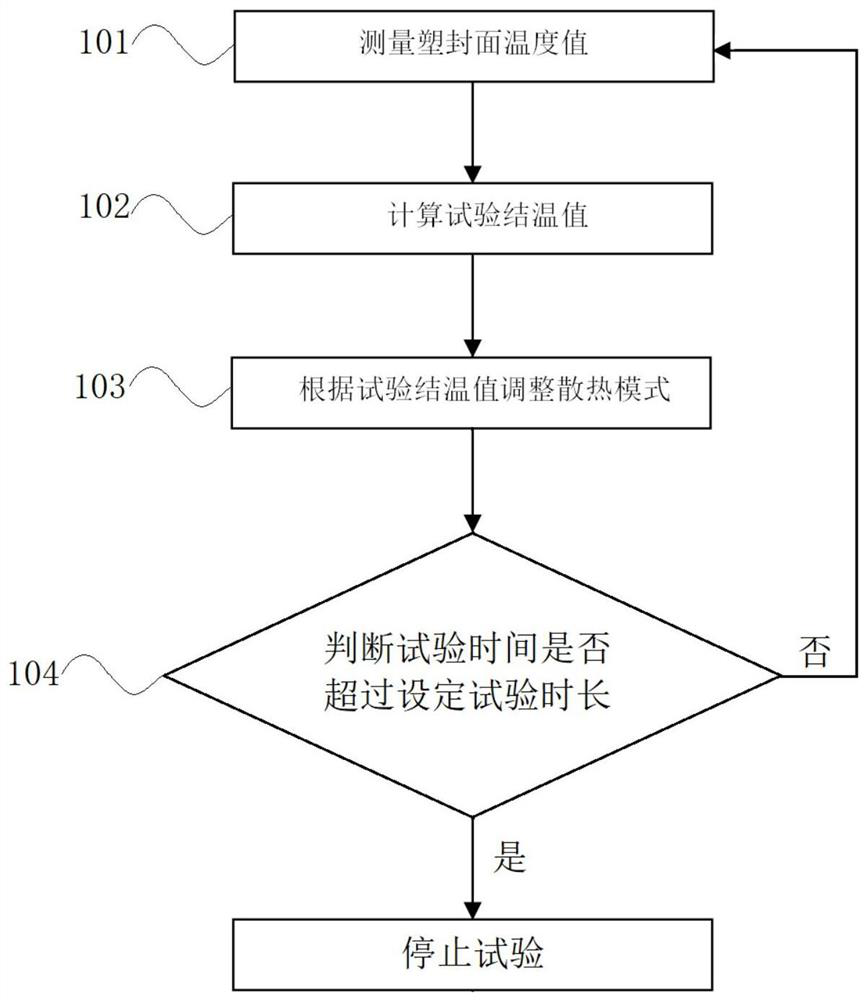

[0039] Aiming at the problems mentioned in the background technology, the present invention provides a surface mount FET burn-in test method, the method flow is as follows figure 1 shown.

[0040] The preparation condition of test method is: select device sample (collectively referred to in the present invention as the components and parts that prepare to carry out test and be the device to be tested), it is placed in the incubator, by lead its S pole and D pole are drawn; In the low gear of the heat dissipation mode, the preparation work for temperature measurement and heat dissipation is turned on. Concrete method steps include:

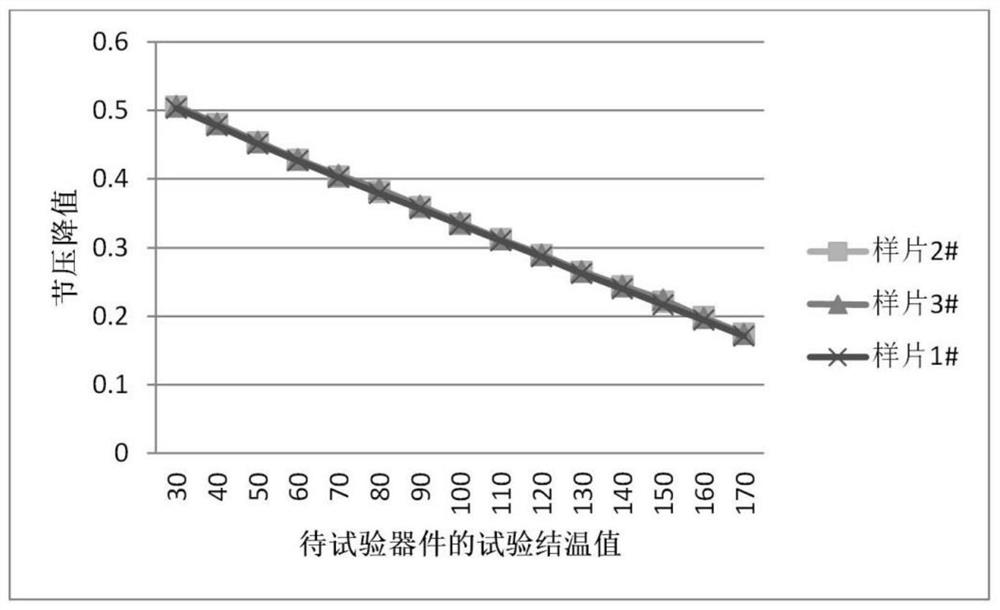

[0041] Step 101: Under different test power conditions of the device to be tested, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com