A distributor device

A dispenser and actuator technology, applied in valve devices, fluid pressure actuation devices, household components, etc., to achieve the effects of improved reliability and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

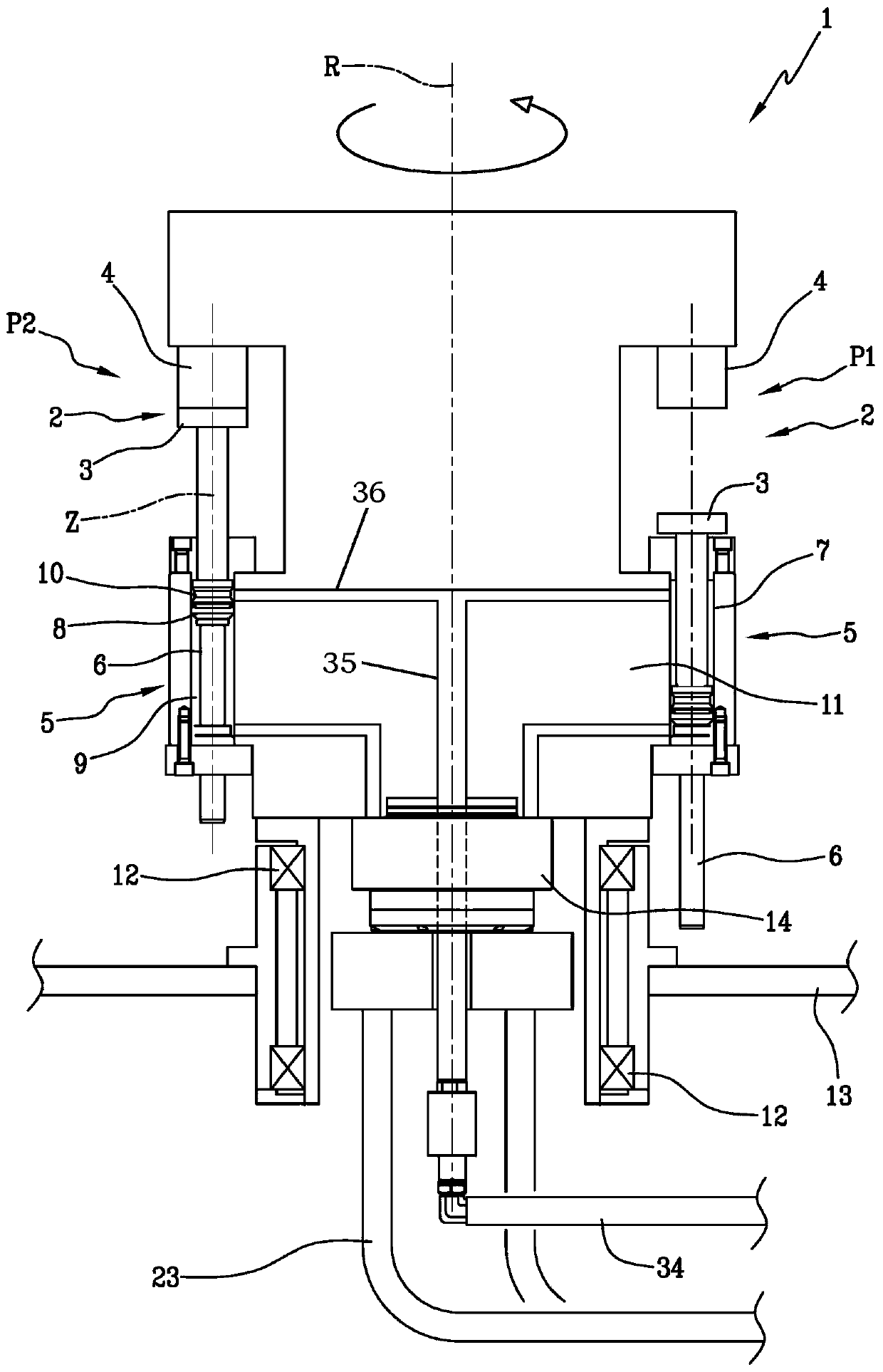

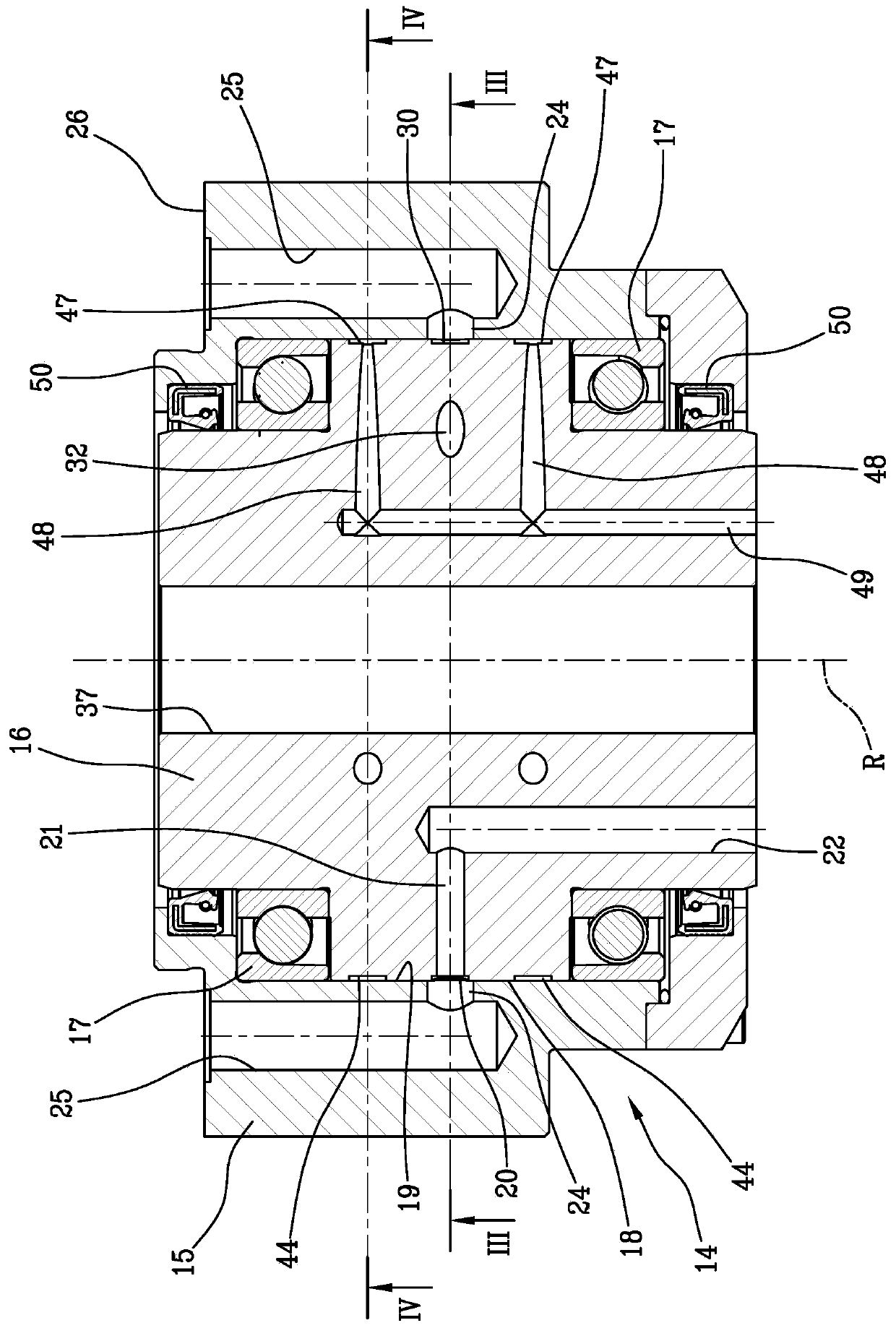

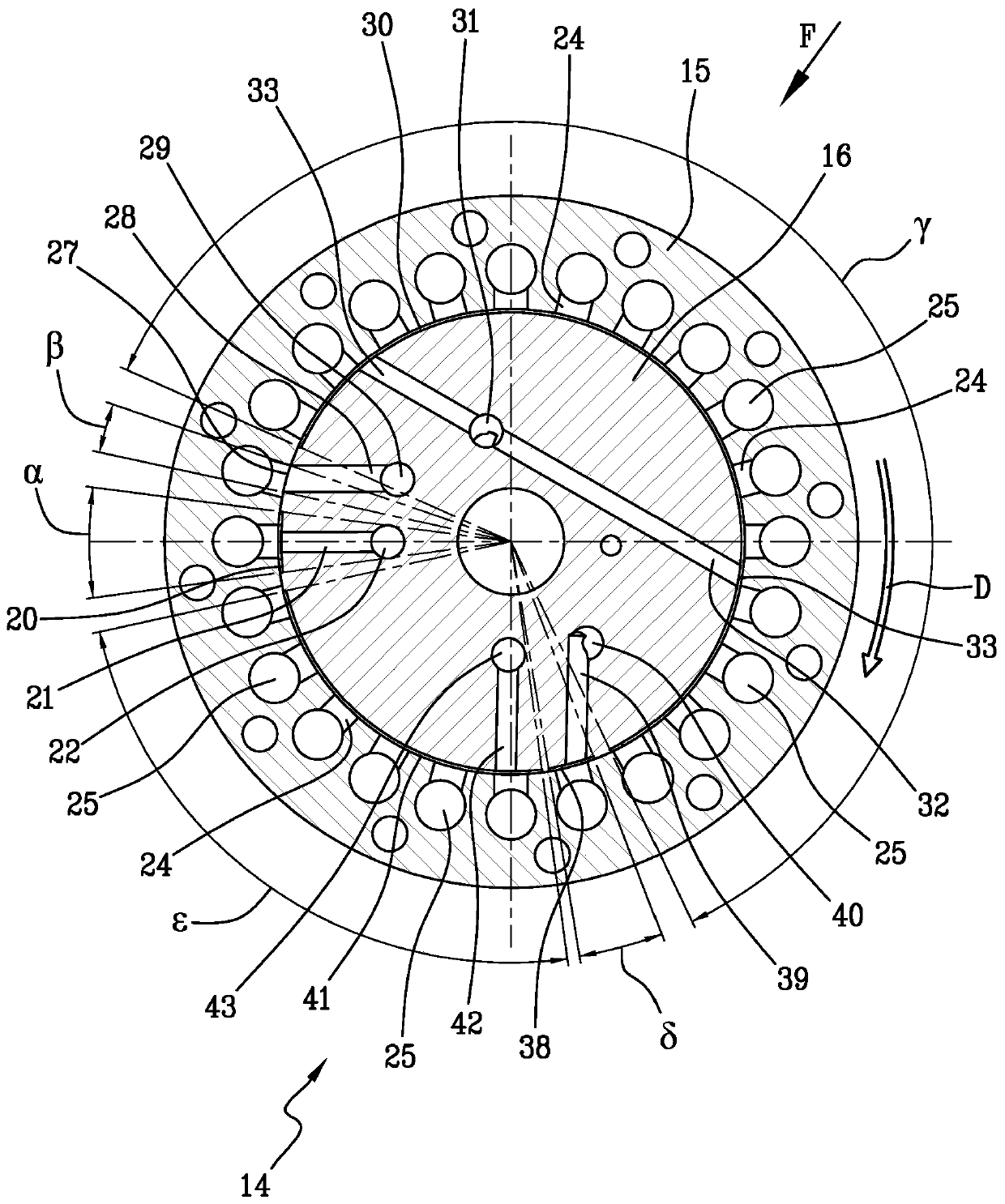

[0055] figure 1 Shown is a forming carousel 1 which is part of an extrusion molding machine for extrusion molding objects starting from a dose of polymeric material. The molding machine comprises an extruder for extruding a continuous extrudate of polymeric material and a cutting device for separating doses of polymeric material from the continuous extrudate. The cutting device is configured to separate the doses by cutting the continuous extrudate of polymeric material at predetermined distances. The molding machine may also comprise transport means, for example similar to a transport carousel, for transporting doses towards one or more molds 2 in which an object of the desired shape will be obtained with each dose. In the example shown, a plurality of molds 2 are provided, the molds 2 being supported by the forming carousel 1 , in particular by the peripheral area of the forming carousel 1 . The forming carousel 1 is rotatable about an axis R, which in the example shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com