Collision energy-absorbing device and front anti-collision beam assembly

A technology of collision energy absorption and front anti-collision beams, which is applied to bumpers and other directions, can solve problems such as the collapse route and direction impact of energy-absorbing boxes, and achieve the effects of improving collision safety, good protection, and increasing buffer time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

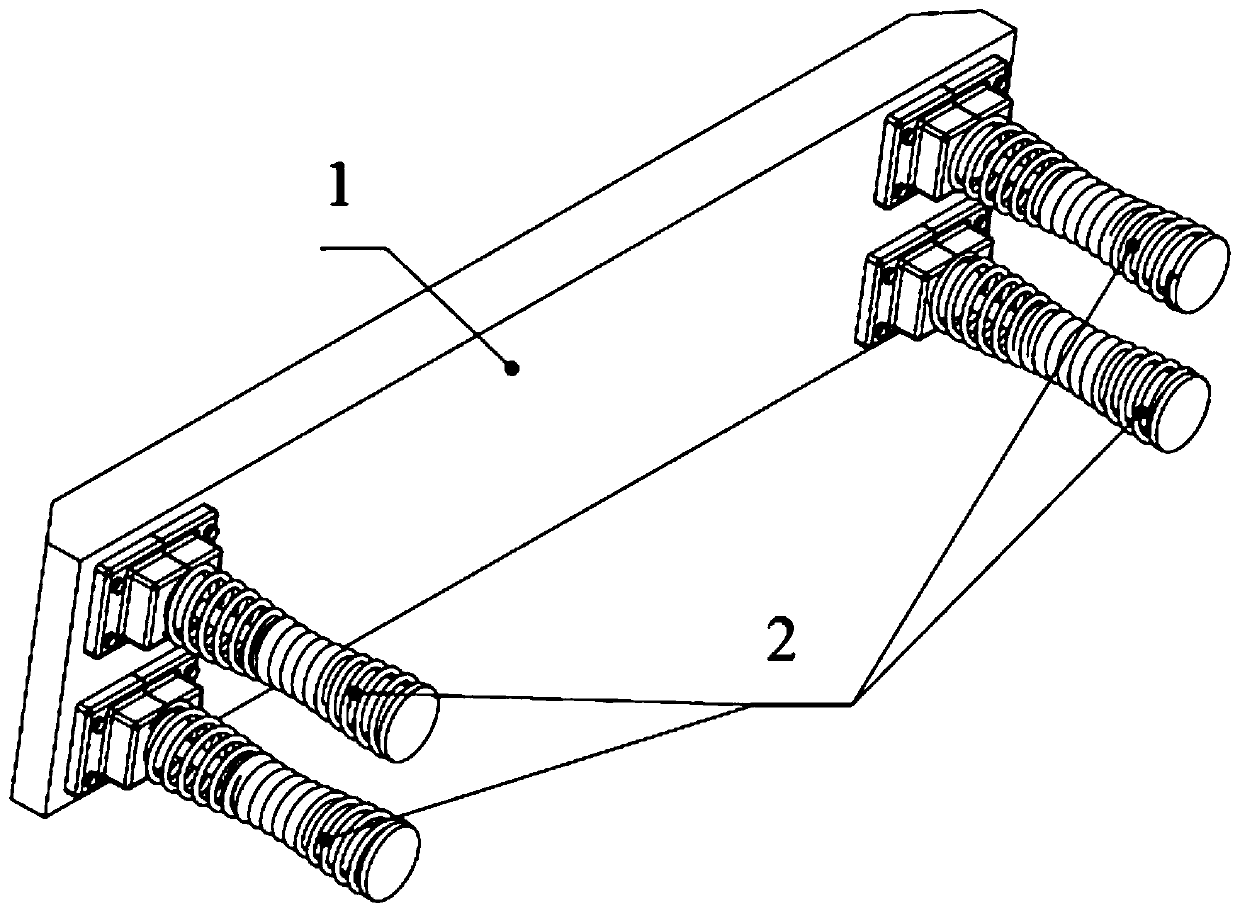

[0027] Such as figure 1 As shown, the front anti-collision beam assembly includes the front anti-collision beam body 1 and four collision energy-absorbing devices; the four collision energy-absorbing devices 2 are fixedly arranged on the same side of the front anti-collision beam body 1 through screw connections; The energy-absorbing device 2 is located at one end of the front anti-collision beam body 1 , and the other two energy-absorbing devices 2 are respectively located at the other end of the front anti-collision beam body 1 . The bolts connecting the anti-collision beam body and the collision energy-absorbing device can be quickly disassembled, and different specifications, models, and sizes of the front anti-collision beam body can be selected according to actual needs.

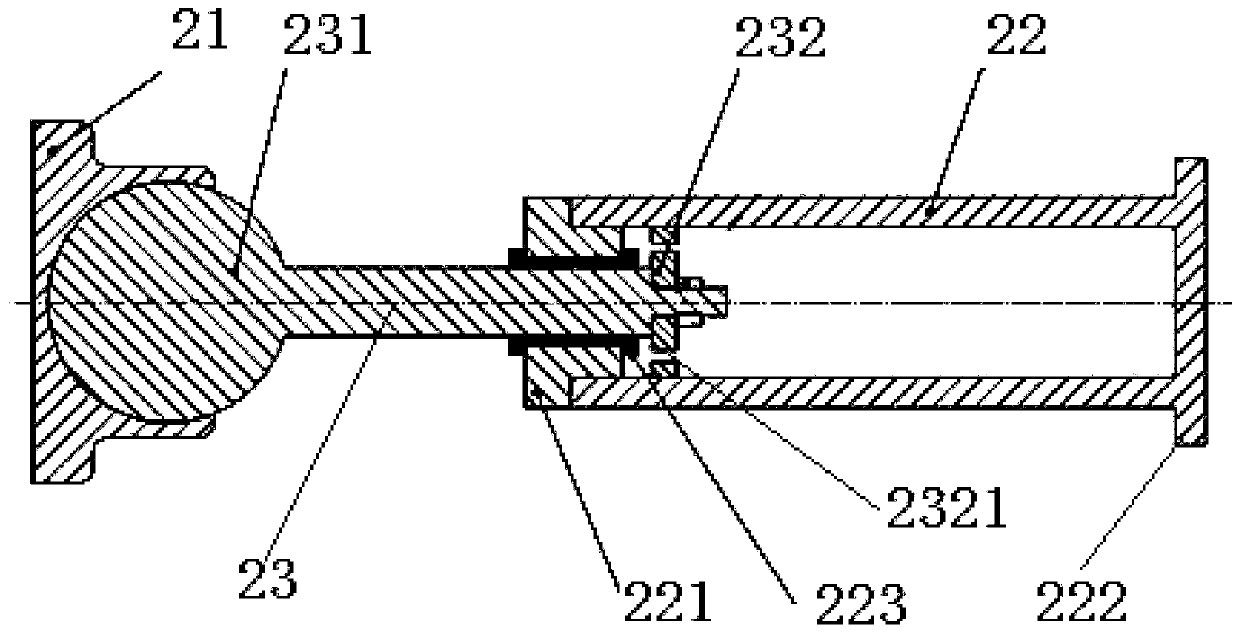

[0028] Such as figure 2 , image 3 As shown, the collision en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com