Installation structure for tower crane

An installation structure and tower crane technology, applied in cranes and other directions, can solve the problem that the tower crane foundation cannot be reused, etc., and achieve the effects of improving installation and demolition work efficiency, reducing environmental pollution and resource waste, and saving construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

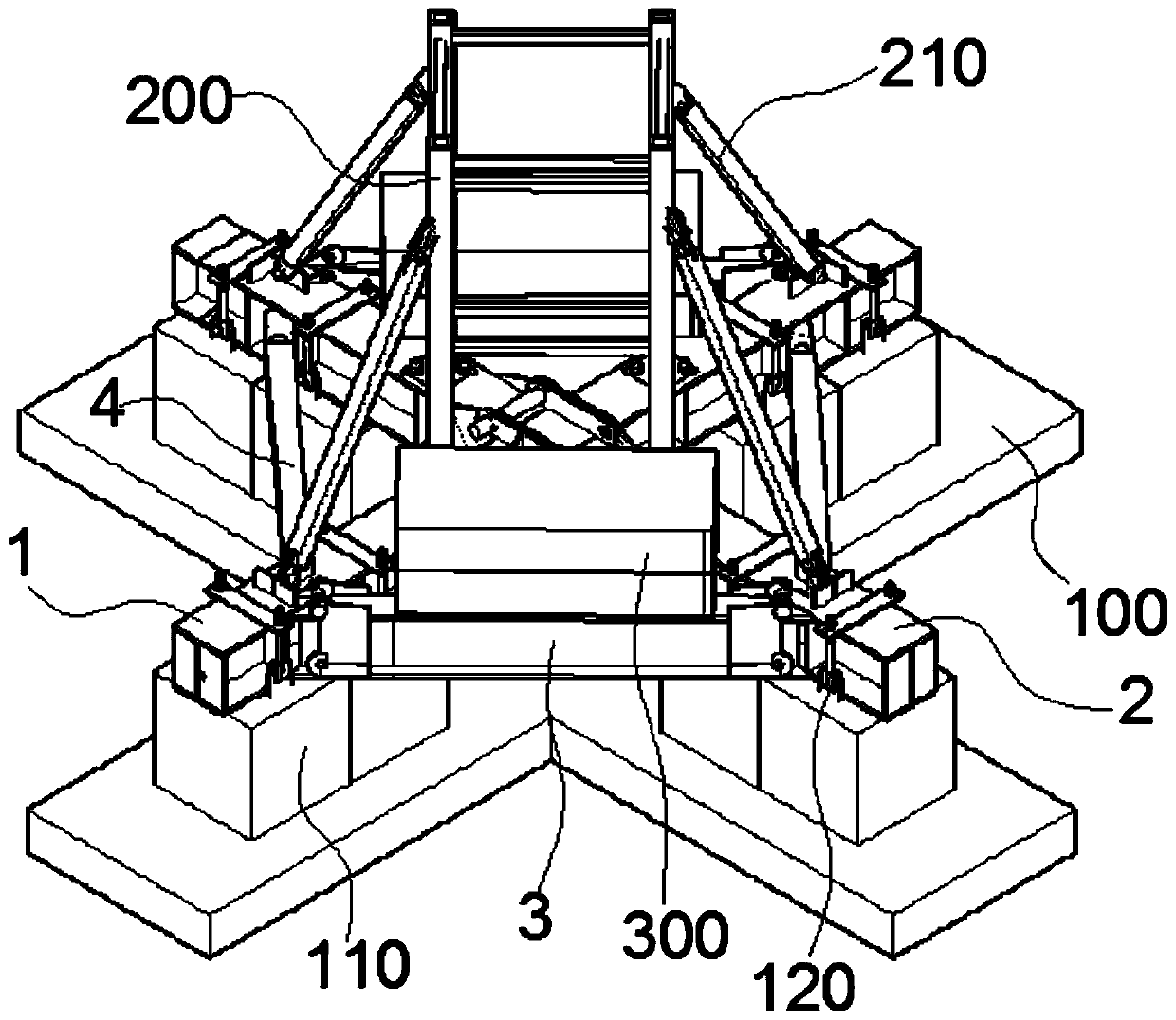

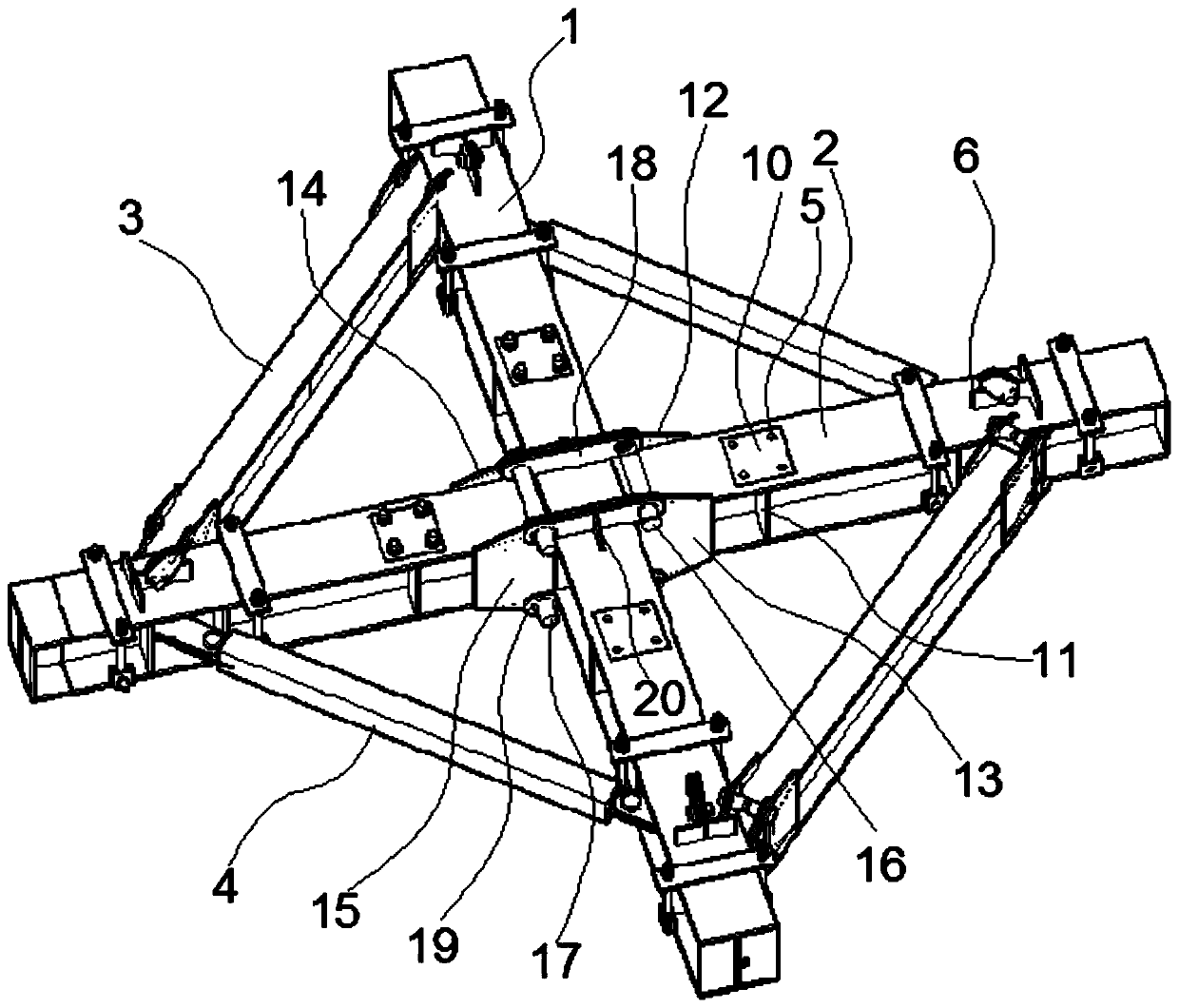

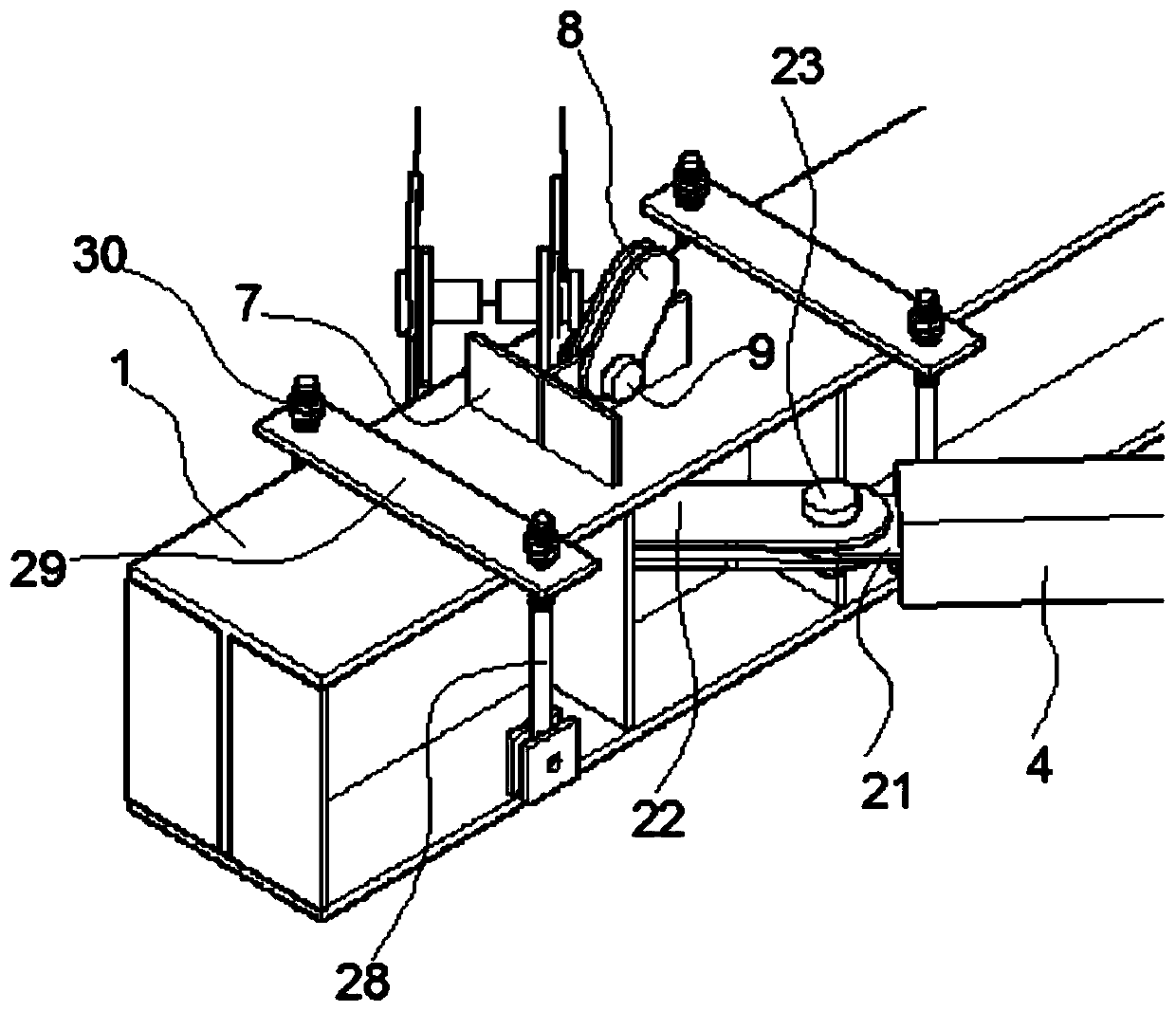

[0024] Tower crane installation structure of the present invention, as figure 1 , figure 2 , image 3 and Figure 4 As shown, including concrete foundation, steel structure foundation and tower crane,

[0025] Wherein, the concrete foundation includes a cross-shaped concrete slab 100 composed of 4 support plates, each of which is provided with a concrete pier 110 on the upper surface of the support plates; the 4 support plates of the concrete slab 100 are integrally formed, and each Two concrete piers 110 are naturally placed on the upper surface of the support plate. Specifically, the concrete slab 100 is a cross-shaped structure of 1.6m wide * 7.0m long * 0.2m thick, which is formed by pouring. When in use, the ground is directly leveled and placed on the ground to support other components. The concrete pier 110 is a square prefabricated concret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com