Automatic machined part measuring system and automatic scoring method

An automatic measurement and machining technology, applied in the direction of measuring devices, optical test defects/defects, instruments, etc., can solve problems such as dissatisfaction of teachers, spending a lot of time, and affecting the quality of training, so as to achieve fair and objective scoring results and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing, technical scheme of the present invention is described further:

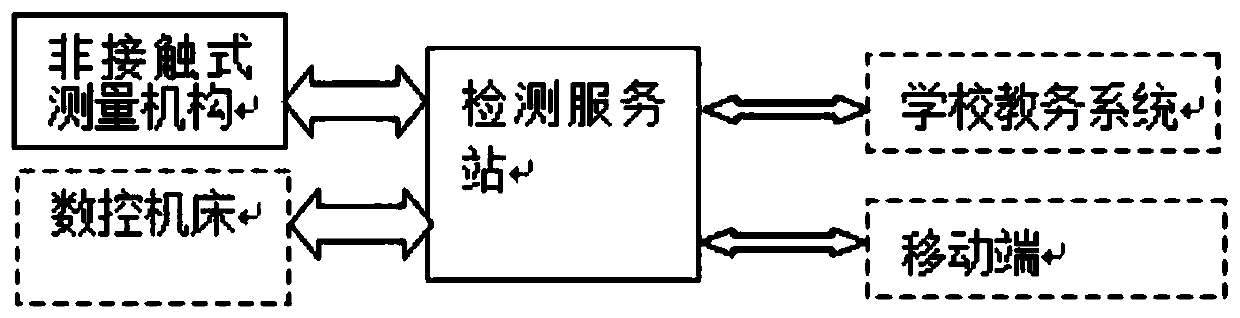

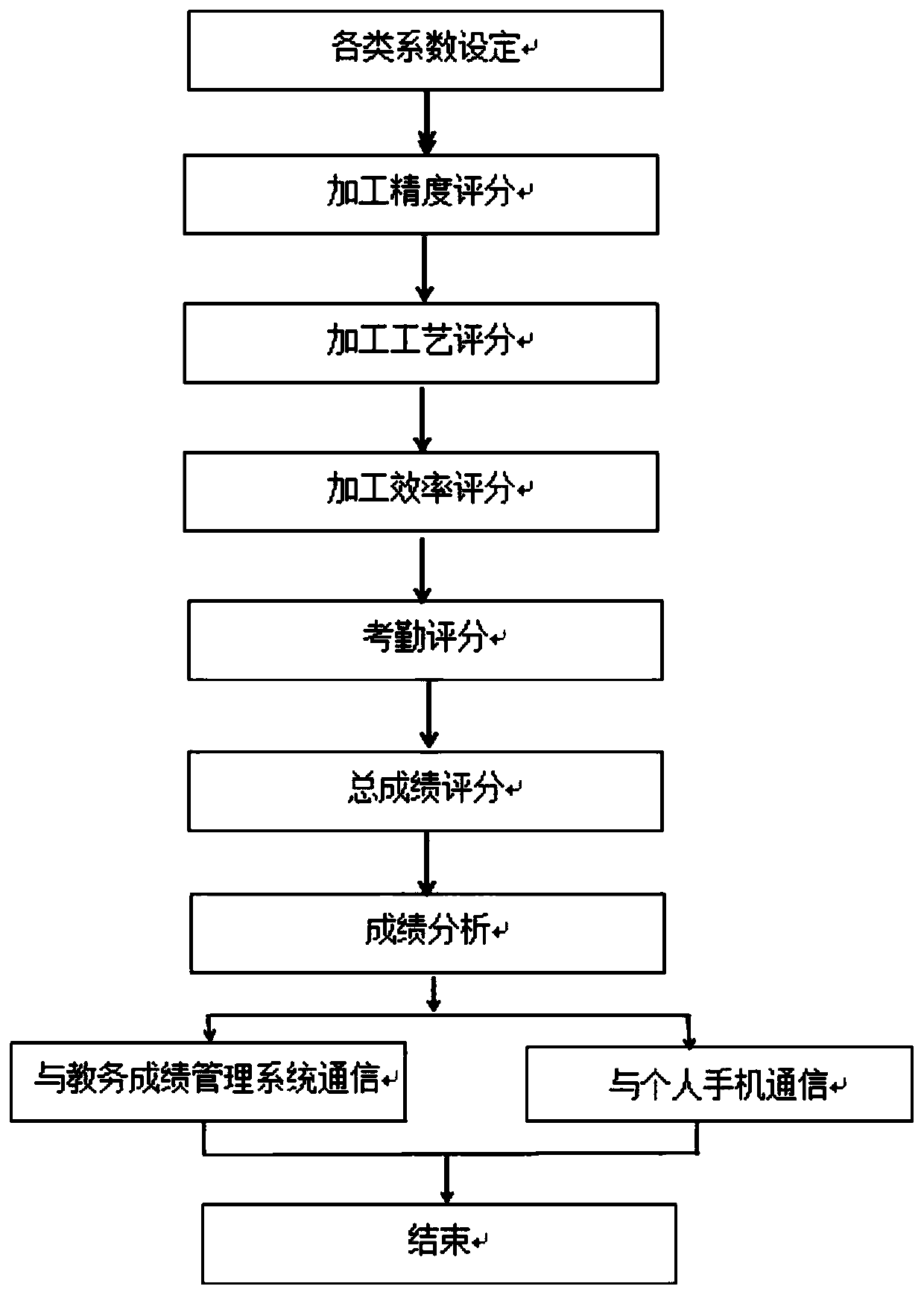

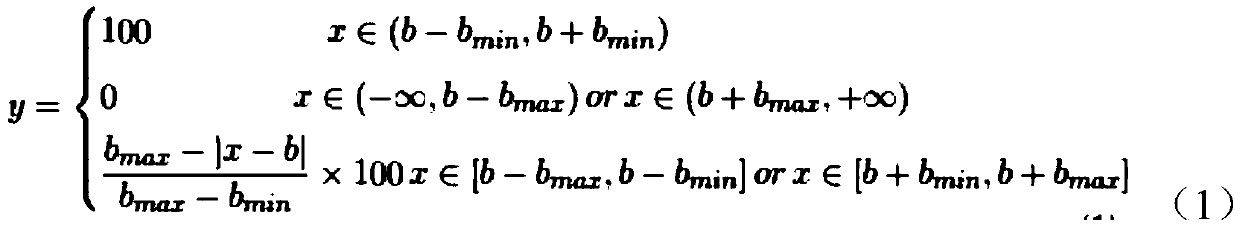

[0041] Such as figure 1 As shown, the automatic measurement system of the present invention includes a non-contact measurement mechanism and a detection service station, and the detection service station is respectively connected with the non-contact measurement mechanism, a numerically controlled machine tool, a school teaching administration system and a mobile phone of a training student through a network, so that The detection service station described above includes a laser, a visual signal processing unit, a data acquisition unit of a CNC machine tool, an automatic scoring unit for machined parts, an interaction unit with the school educational affairs system, and a mobile terminal interaction unit; The main data comes from the measurement value of the non-contact measuring mechanism; the work efficiency of students is automatically collected from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com