Anti-disengagement harness plug structure for automobile lamp and assembly method

A technology for automotive lamps and assembly methods, which is applied in the direction of coupling devices, parts of connecting devices, and connecting/disconnecting devices, which can solve problems such as poor contact and disconnection of power wires and plugs, so as to save development costs and prevent safety accidents , the effect of ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

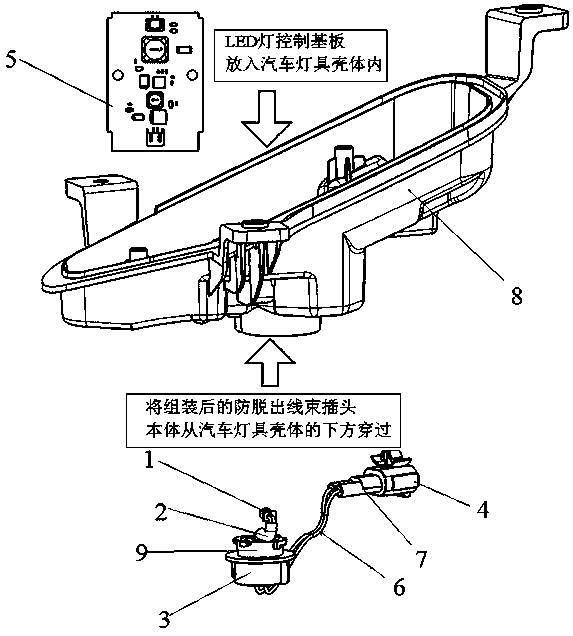

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

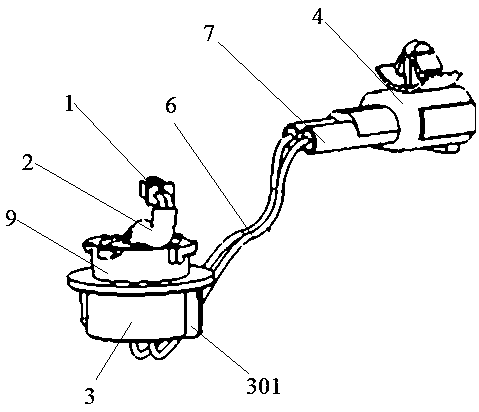

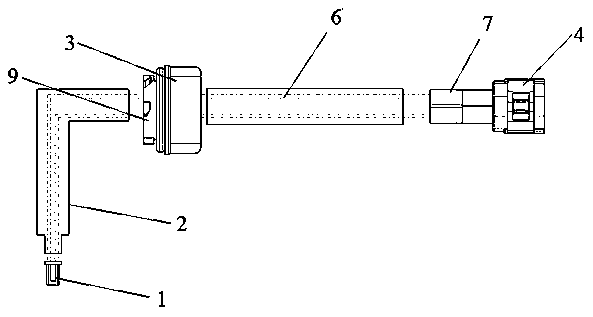

[0027] Such as figure 1 and figure 2 As shown, the anti-extraction wire harness plug structure for automotive lamps of the present invention includes a plug body 1, a heat shrinkable tube 2, a lamp socket mounting base 3 and a wire interface 4,

[0028] The plug-in end of the plug body 1 is plugged into the socket on the LED lamp control substrate 5 in the automobile lamp, and the other end of the plug body 1 is installed on one end of the heat-shrinkable tube 2, and the heat-shrinkable tube 2 is another One end is connected with the lamp socket installation base 3, and the lamp socket installation base 3 is used to be screwed on the automobile lamp housing, and the other end of the plug body 1 is connected with an electric wire 6, and the electric wire 6 runs through the heat The shrink tube 2 and the socket installation base 3, the electric wire 6 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com