A system and a method for collecting and handling dust in a paper-making environment

A dust and environmental technology, applied in the direction of textiles and paper, paper, paper machines, etc., can solve the health hazards of workers, increased dust fire, cleaning problems and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

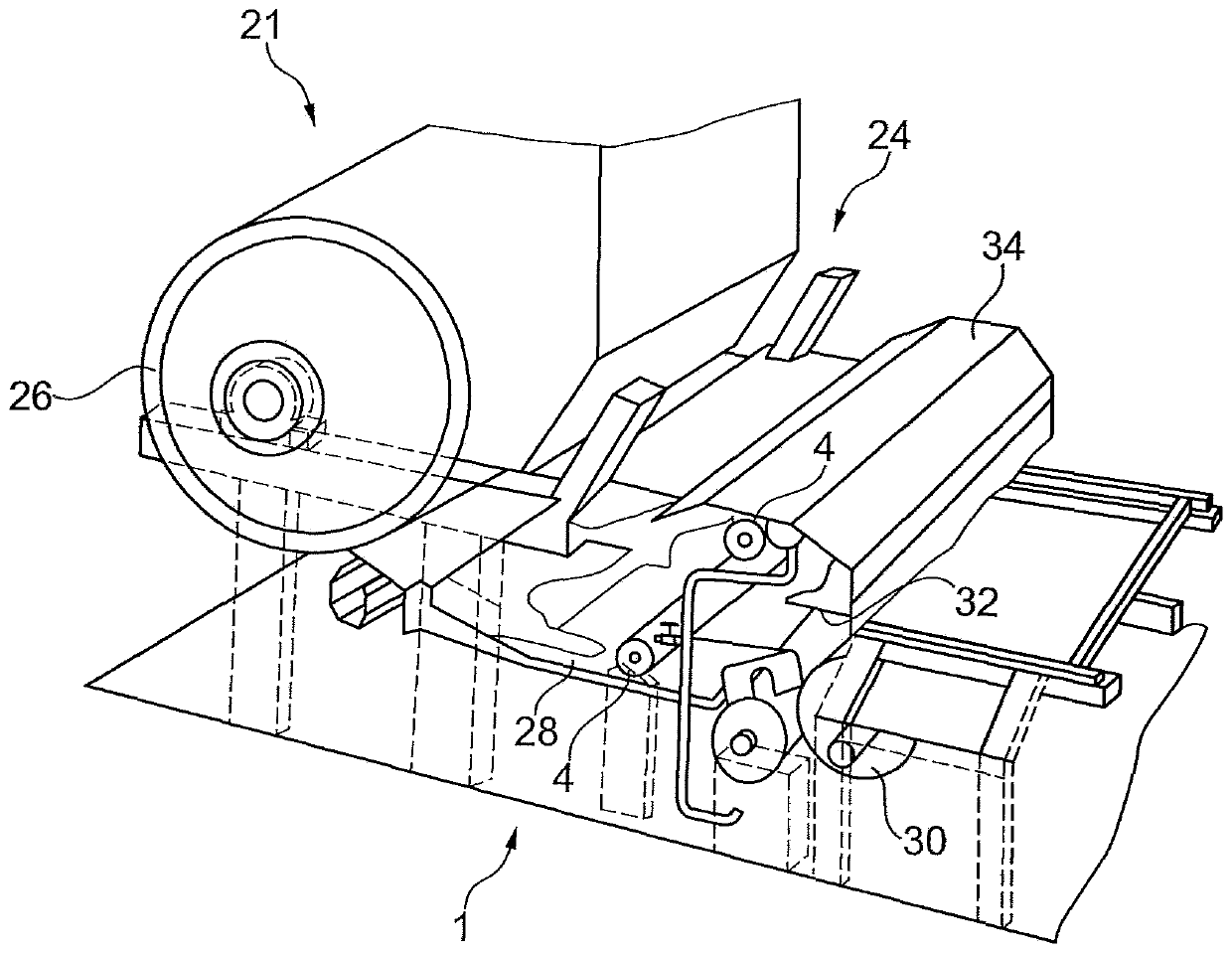

[0023] first refer to figure 1 , which shows a perspective view of a portion of a paper machine employing an embodiment of a dust handling system. Reference numeral 21 denotes the environment in which the present invention will be used, and reference numeral 24 denotes a part of a paper machine. In practice, the paper machine includes a cylinder 26 , which is usually a drying cylinder, such as a Yankee dryer, from which the dried paper web 28 is further conveyed to be wound into a roll 30 . At this stage, a large amount of dust from the papermaking process can fill the environment of the paper machine. This is particularly the case when the paper web 28 has been creped from the cylinder 26 by the doctor blade. Airborne dust can contain fibers as well as residues from clays, starches and chemicals used in the papermaking process. In order to reduce health hazards to workers and the risk of fire, the paper machine is provided with a dust handling system generally designated b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com