A High-Speed Heating And Energy Saving Apparatus

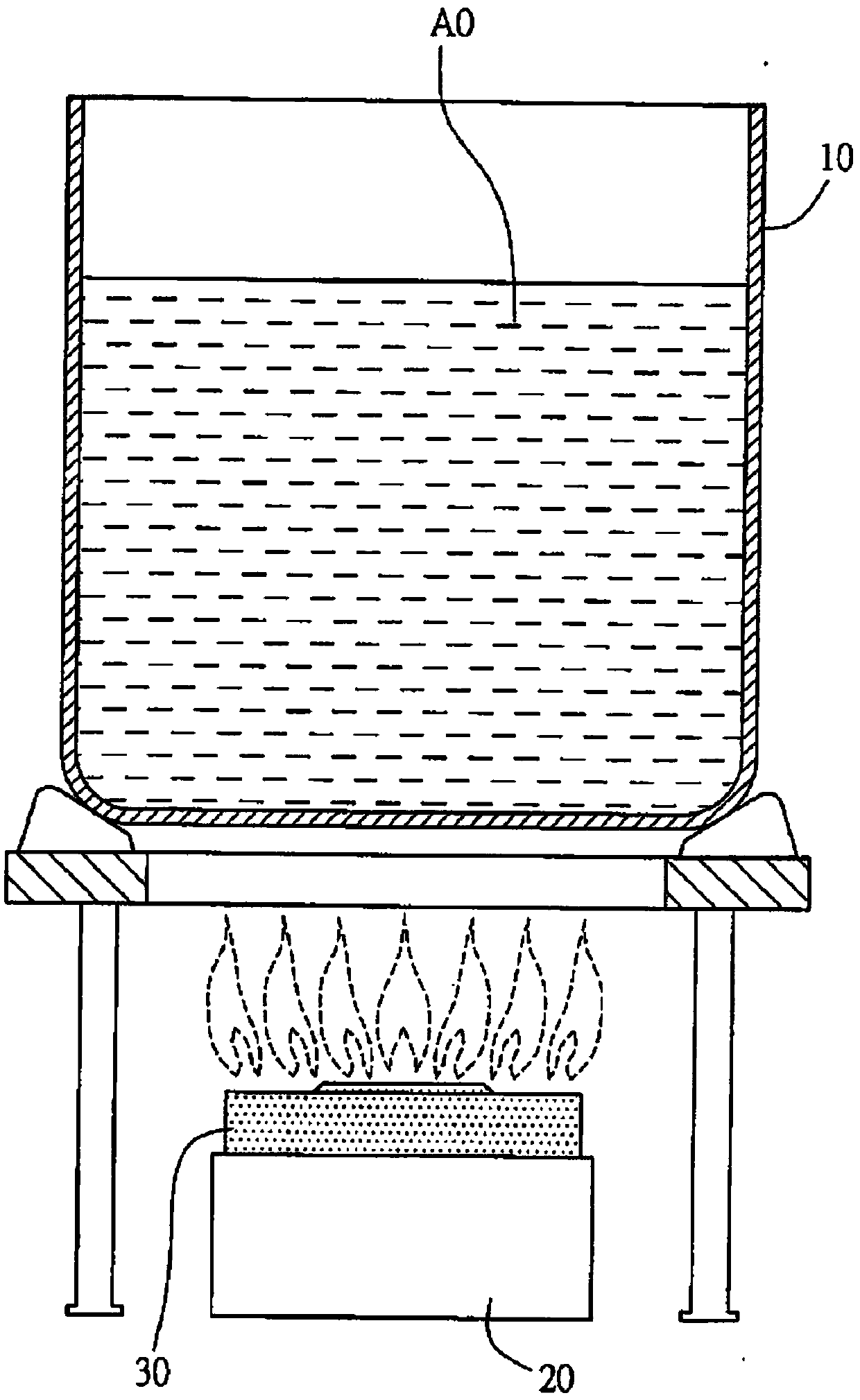

A high-speed, vertical barrel technology, applied to utensils with enlarged heating surfaces, kitchen utensils, utensils for boiling water, etc., can solve the problems of low heat conduction efficiency, long boiling time, waste of fuel, etc. The effect of shortening the boiling time and increasing the flame height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In addition, this invention is not limited to embodiment described below.

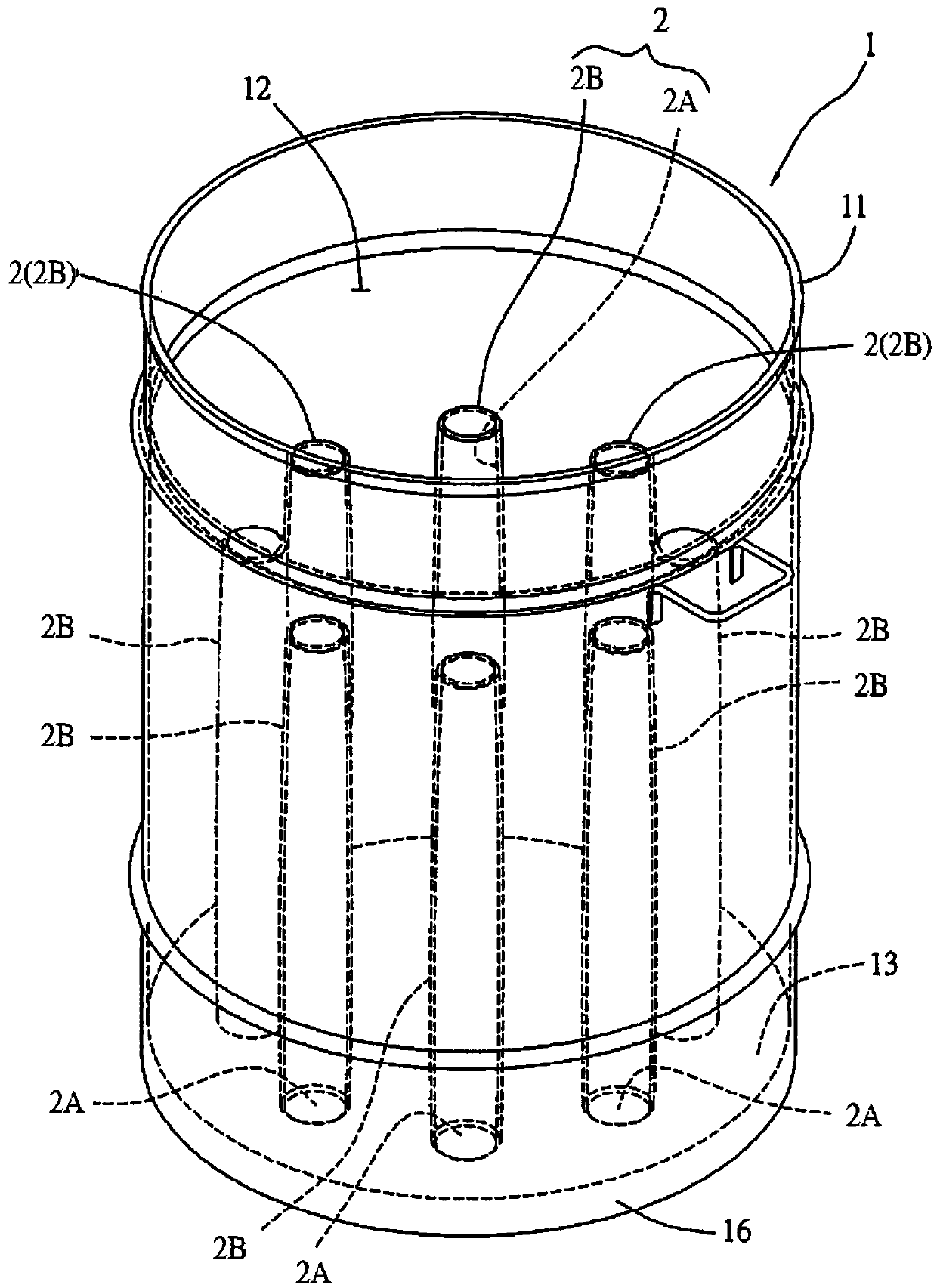

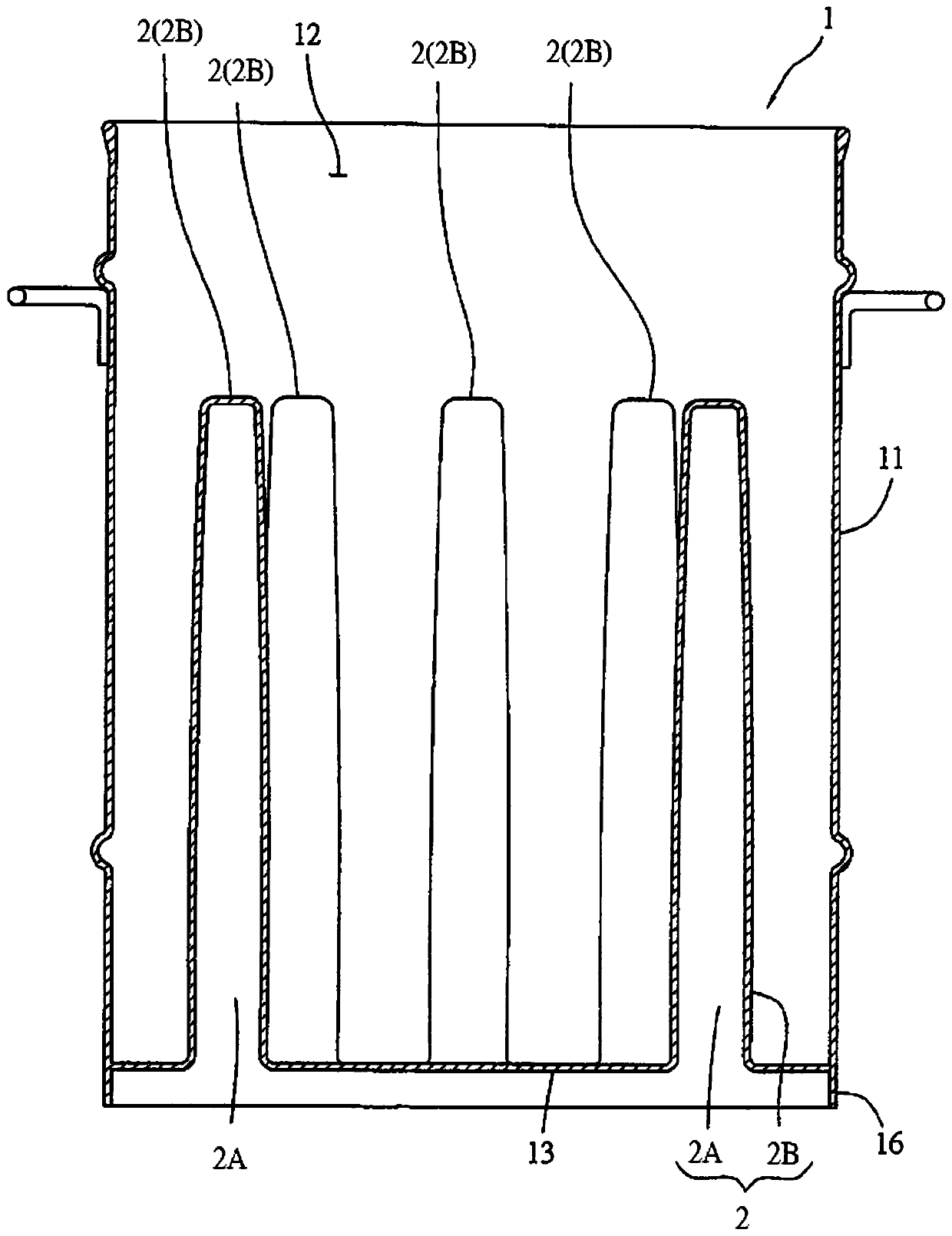

[0044] The first embodiment of the present invention is as Figure 2 to Figure 6 shown. First, refer to figure 2 , image 3 , the present invention is a high-speed heat-saving energy-saving drum 1, which is characterized in that it has at least a vertical drum 11, and the vertical drum 11 has at least a recessed chamber 12, and at least a bottom 13 is provided below the vertical drum 11, and a recess is provided on the bottom 13. There is at least one convex hollow cylinder 2; the concave surface of the convex hollow cylinder 2 on the heating side is the heat collecting cover groove 2A; the convex surface of the convex hollow cylinder 2 on the surface of the chamber is the heat conduction cover 2B. The heat collecting cover groove 2A and the heat conducting cover 2B are integrally f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com