Tearless candle

A technology of candles and wicks, which is applied in the production of candles and fatty acids. It can solve the problems of short ignition time and melting of candles, and achieve the effects of long burning time, complete combustion and increased flame height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] As shown in Fig. 1 and Fig. 2, the shape of the tearless candle of the present invention is a traditional cylindrical shape, and the combed cotton fiber bundle is used as the candle wick 1, palm wax is made of the candle body 2, and the candle wick 1 spreads over In the whole candle body, palm wax is adsorbed on the candle wick fibers and fills up the spaces between the candle wick fibers, wherein the fibers account for 12% and the wax accounts for 88% by weight. When making it, put the carded and fluffy fiber strips into molten palm wax and soak them to make them absorb completely, and then move them to the mold to cool and solidify. Or put the carded fluffy fiber strips in the mold, and then inject molten palm wax until the gaps between the fiber strips are completely filled with palm wax, and then cool and solidify. After being ignited during use, because the candle wick spreads over the entire cross section, the flame also burns throughout the entire cross section, ...

Embodiment 2

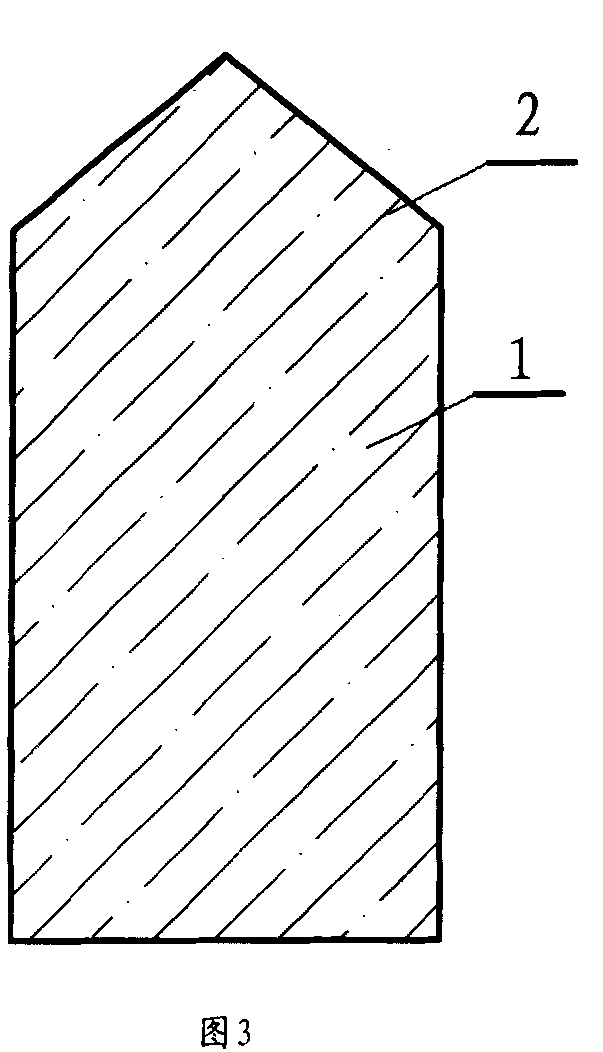

[0022] As shown in Fig. 3 and Fig. 4, the appearance of the tearless candle of the present invention is also cylindrical, with the candle wick 1 made of the bulky layered cotton fiber sheet through carding, and tallow wax is made of candle body 2, and the candle wick 1. It is wound into a helical shape and fills the whole candle body. The tallow wax is adsorbed on the candle wick fibers and fills up the gaps between the candle wick fibers. The fiber accounts for 2% and the wax accounts for 98% by weight. When making it, first wind the carded layered cotton fiber sheet into a spiral shape, soak it in molten tallow wax to make it completely absorbed, and then move it to a mold to cool and solidify. If it is made into a flat block or strip Shaped ones only need to cut the layered cotton fiber sheets into corresponding shapes, dip them in molten tallow tree wax to make them absorb completely, and then move them into molds to cool and solidify. Or directly put the cut and formed la...

Embodiment 3

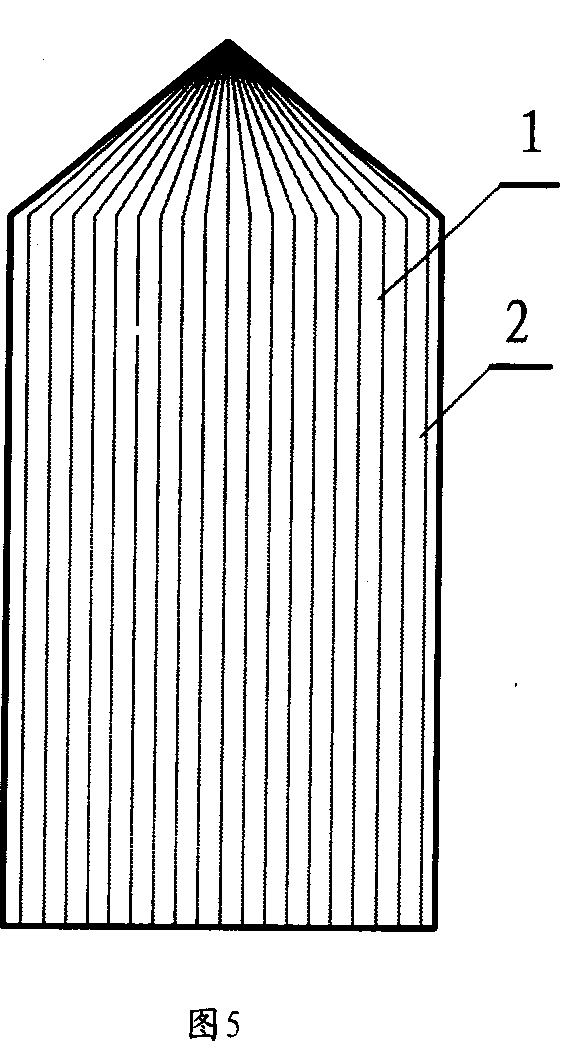

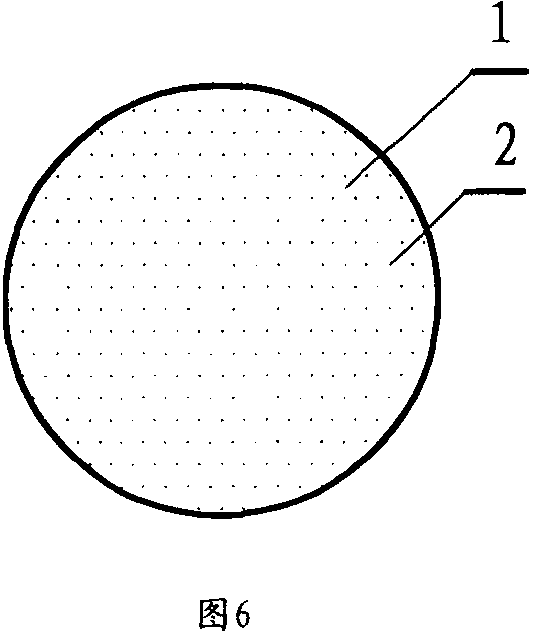

[0024] As shown in Fig. 5 and Fig. 6, the appearance of the tearless candle of the present invention is cylindrical, and the candle wick 1 made by the cotton fine wire bundle through fiber drawing, the animal wax is that the candle body 2 constitutes, and the candle wick 1 is filled up. In the whole candle body, the animal wax is adsorbed on the candle wick fiber and fills up the space between the candle wick fibers, wherein the fiber accounts for 22% and the wax accounts for 78% by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com