Clamping Tooling for Large Capacity Adjustment Shell

A large-capacity, clamping technology, applied in the field of clamping tooling, can solve the problems of inconvenient clamping, easy loosening, and insufficient clamping stability of large-capacity adjustment shells, and achieve convenient clamping, not easy to loosen, stable and reliable clamping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

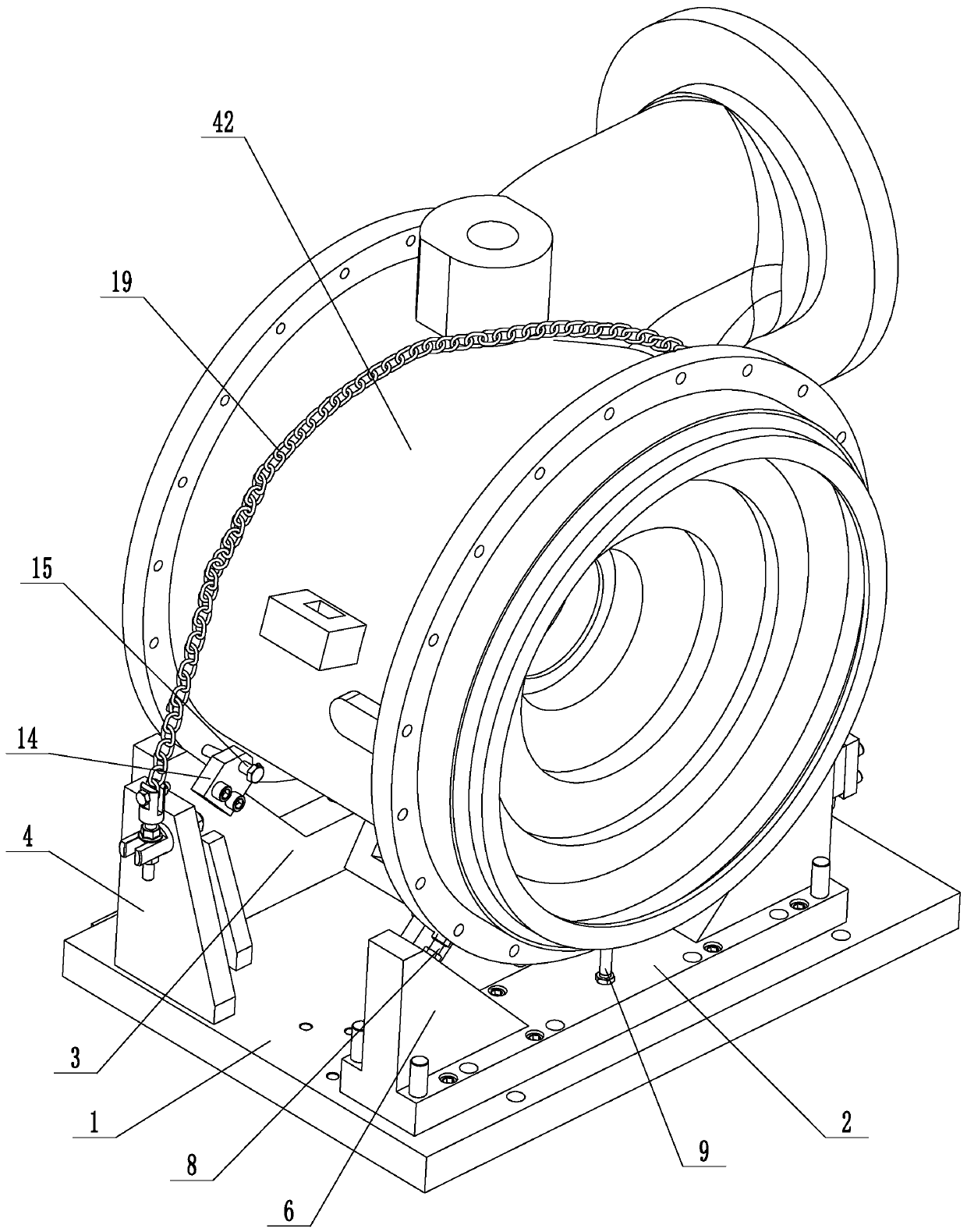

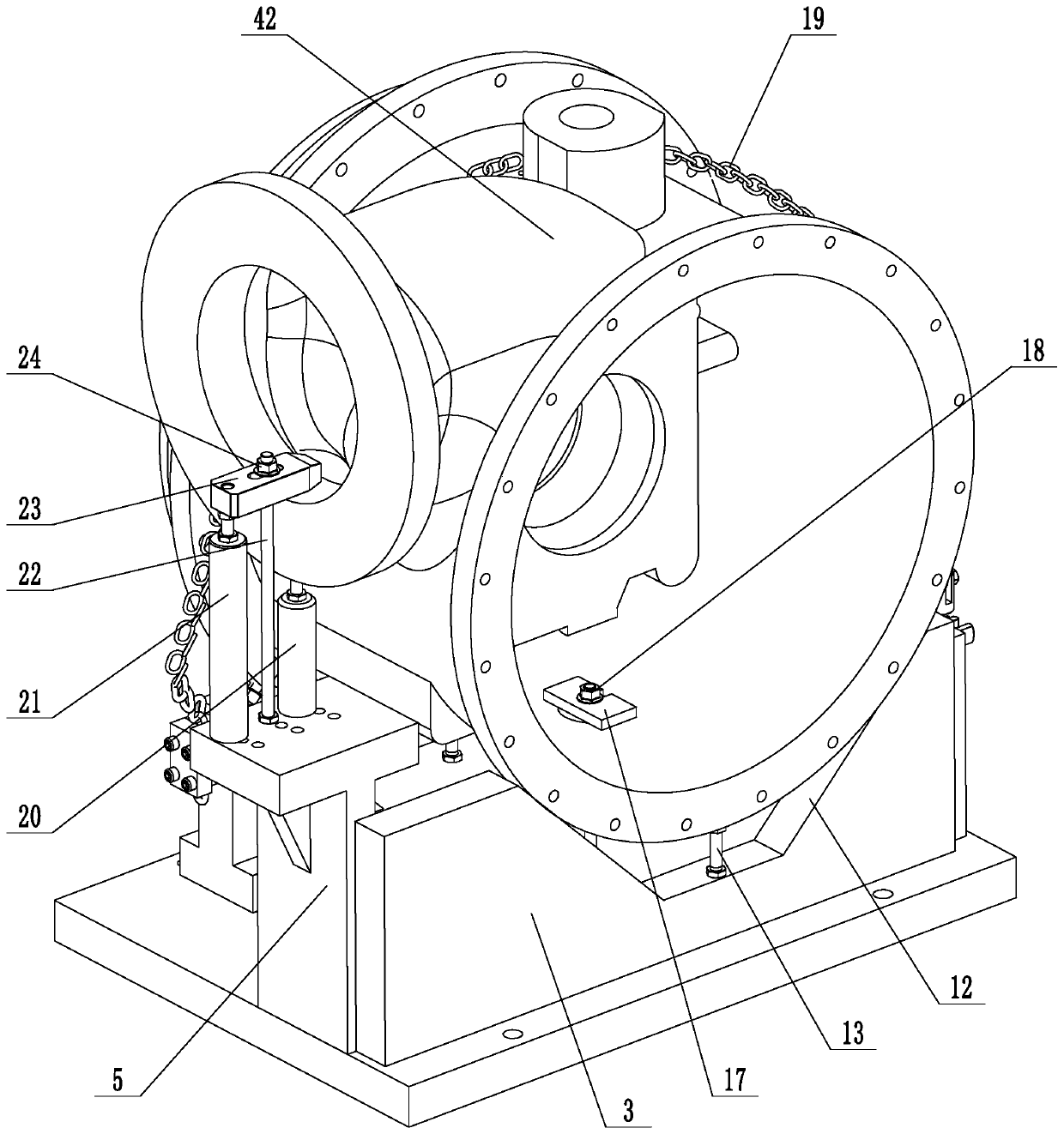

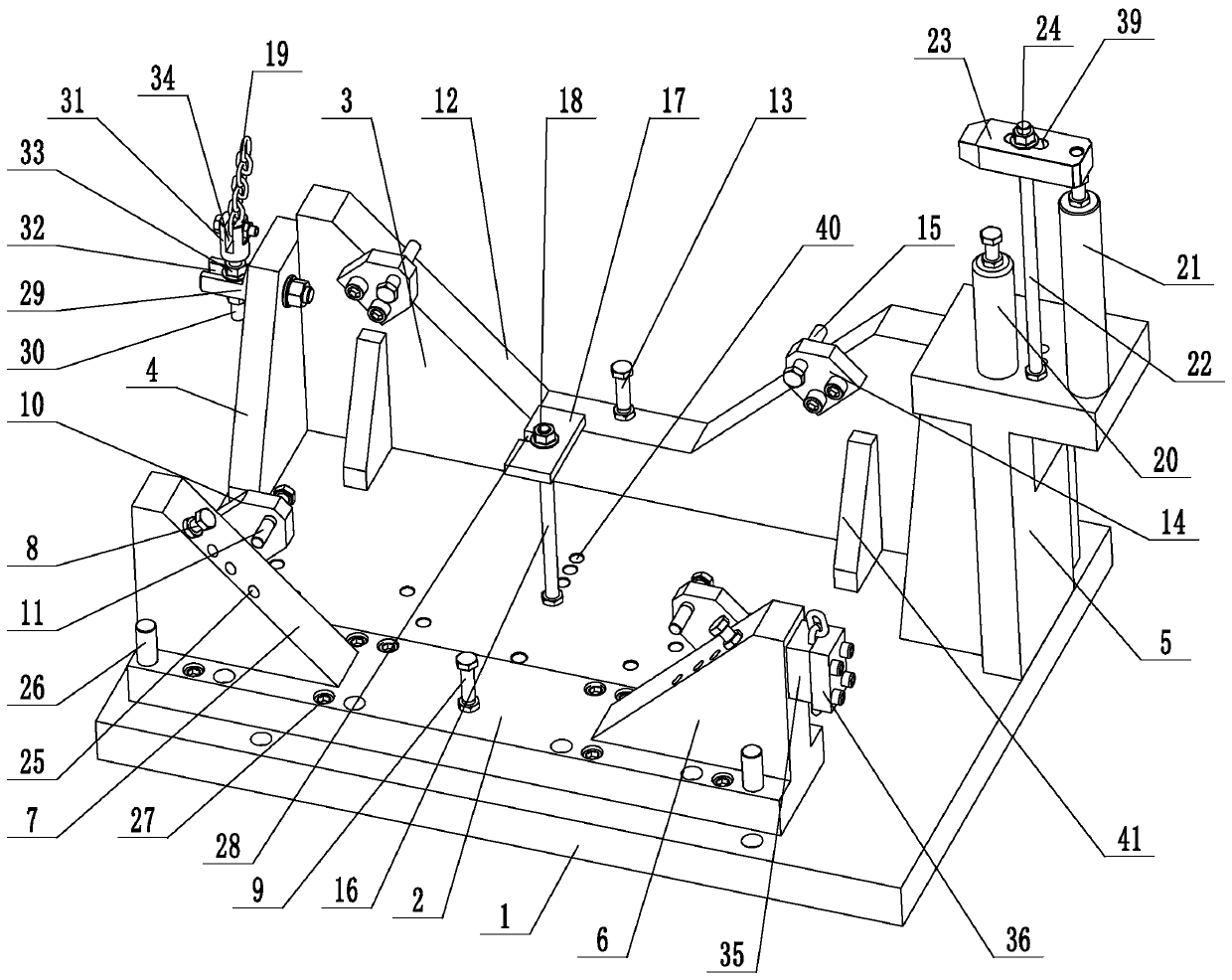

[0023] Embodiment: A clamping tool for a large-capacity regulating shell (see attached figure 1 To attach Figure 4), including the base 1, the mounting seat 2, and the positioning block 3, the mounting seat and the positioning block are respectively arranged on the front and rear sides of the base, and the left and right vertical plates 5 are respectively provided on the left and right sides of the base close to the position of the positioning block, The left and right ends of the mounting base are all provided with support slanting blocks 6, and the support slanting blocks are provided with a support surface 7 which is provided with an inclination. Rod 9, front bearing 10 is all installed on the rear side of two supporting inclined blocks, and the front bearing is connected with the front adjustment screw rod 11 that is arranged forward, and the front adjustment screw rod is placed above the support surface; Trapezoidal groove 12, rear bottom strut 13 is installed on the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com