Clamping and positioning process for part with multiple inclined surfaces

A multi-slope and parts technology, which is applied in the direction of positioning devices, workpiece clamping devices, metal processing machinery parts, etc., can solve the problems of multi-slope parts that cannot be clamped and cannot be aligned, and achieve low technical requirements for locking work. Overall cost and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

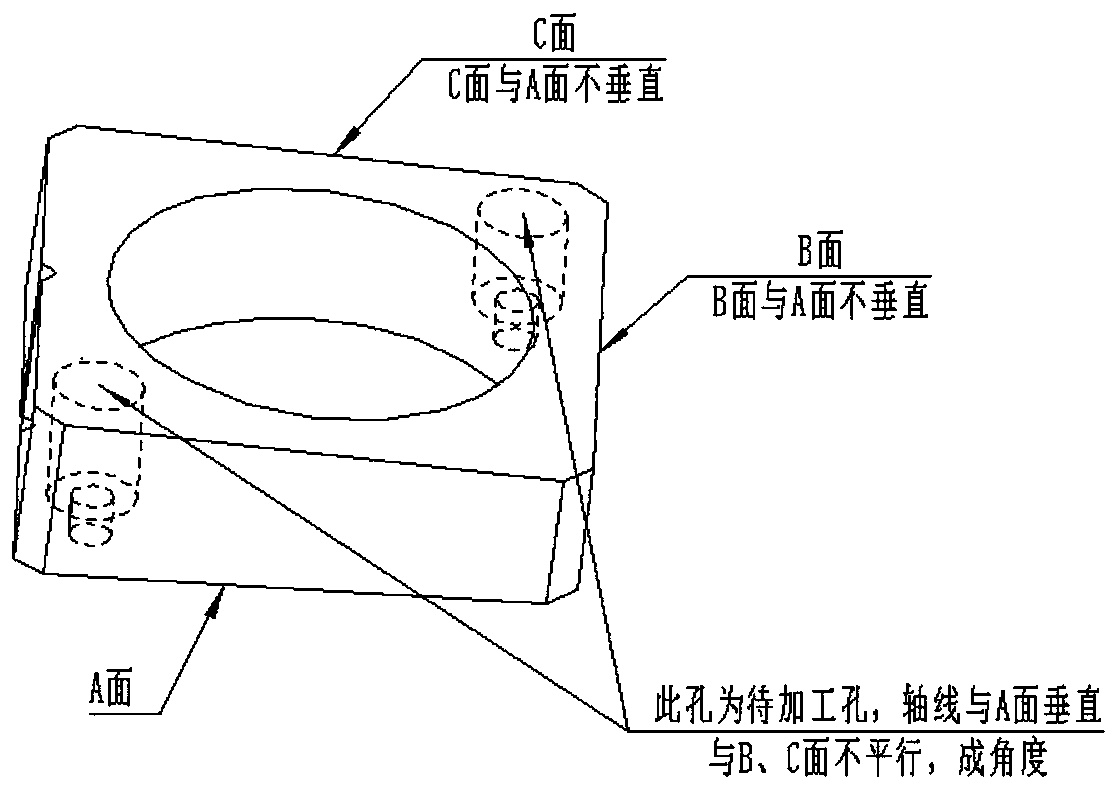

[0035] 1. For multi-slope parts, this process needs to process the remaining countersunk holes after the previous process, such as figure 1 shown.

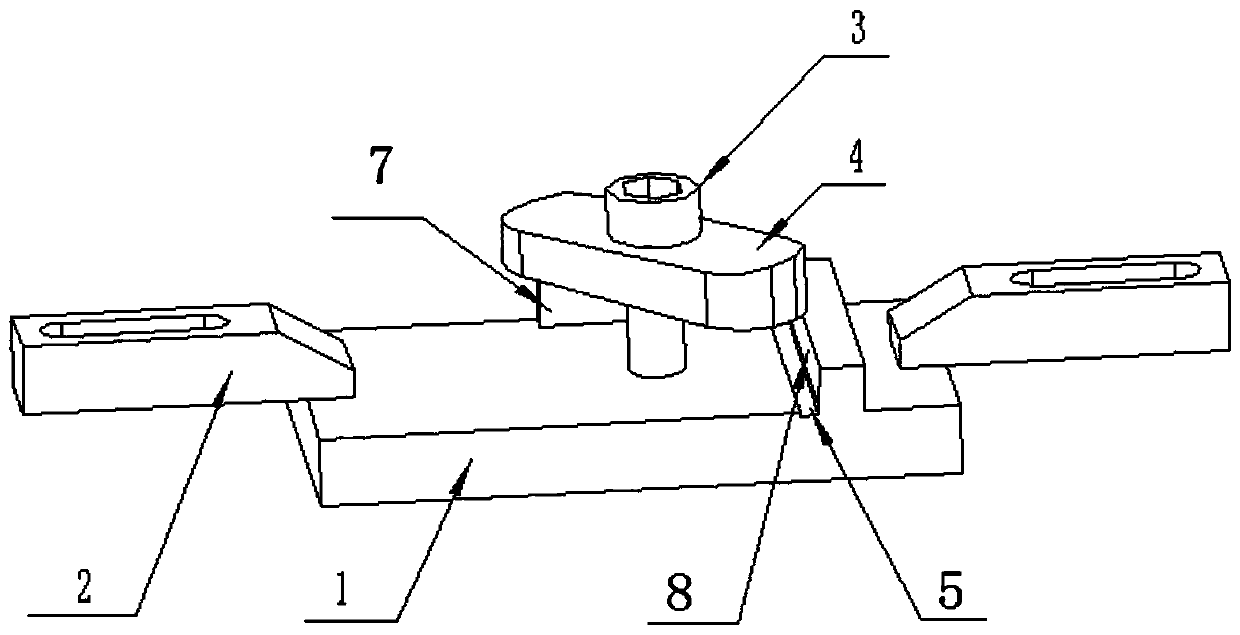

[0036] 2. The tooling required for processing the reverse face is divided into four parts, 1) tooling base; 2) pressure plate; 3) bolts; 4) inclined cover (such as figure 2 shown);

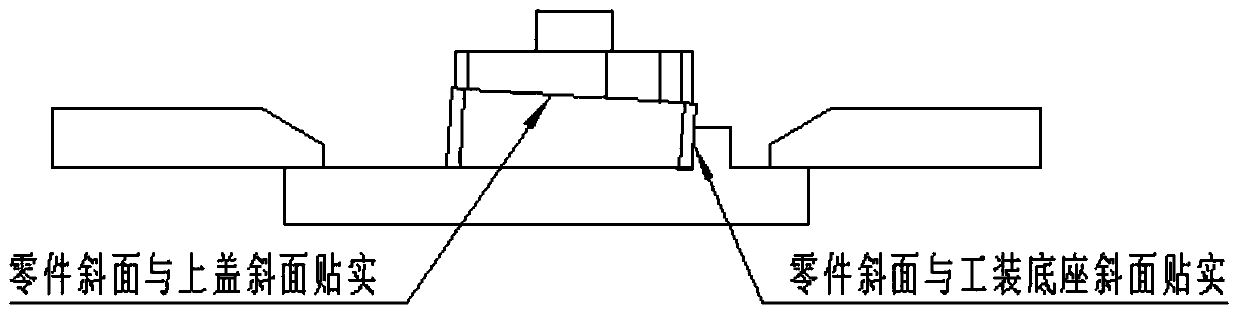

[0037] 3. Straighten the surface a of the tooling base, within 0.03mm of runout, press the pressure plate on the position shown in the figure (both ends of the tooling base), the surface perpendicular to the countersink hole to be processed is firmly attached to the bottom surface of the tooling, and the two slopes in the upper right corner are aligned with the two sides of the tooling. The slopes at the same angle are realistic, the slopes of the upper surface and the slope of the cover on the slope are firmly attached, and are pressed tightly with bolts. Machining origin X0: tooling straight face a, Y0: tooling straight face b, Z0: tooling big fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com