A pneumatic liquid hose valve

A hose valve and liquid technology, which is applied in the direction of diaphragm valves, valve devices, engine components, etc., can solve the problems of solution corrosion, low clamping force, unusability, etc., to achieve improved clamping force, high clamping force, Avoid the effect of channeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described below in the form of specific examples, but the present invention is by no means limited to the following examples.

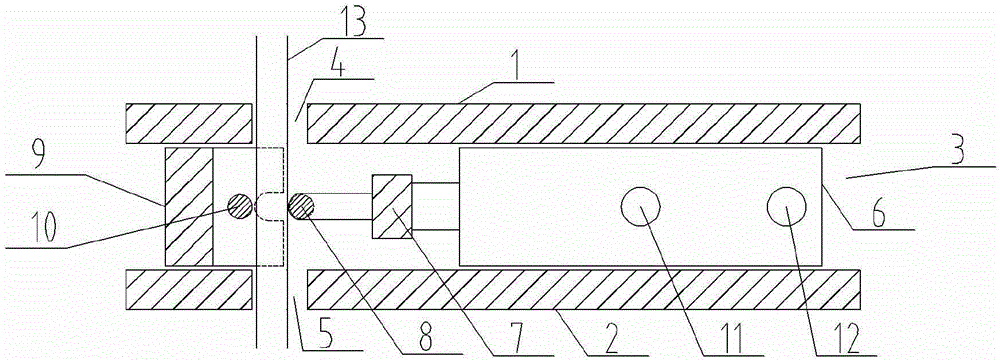

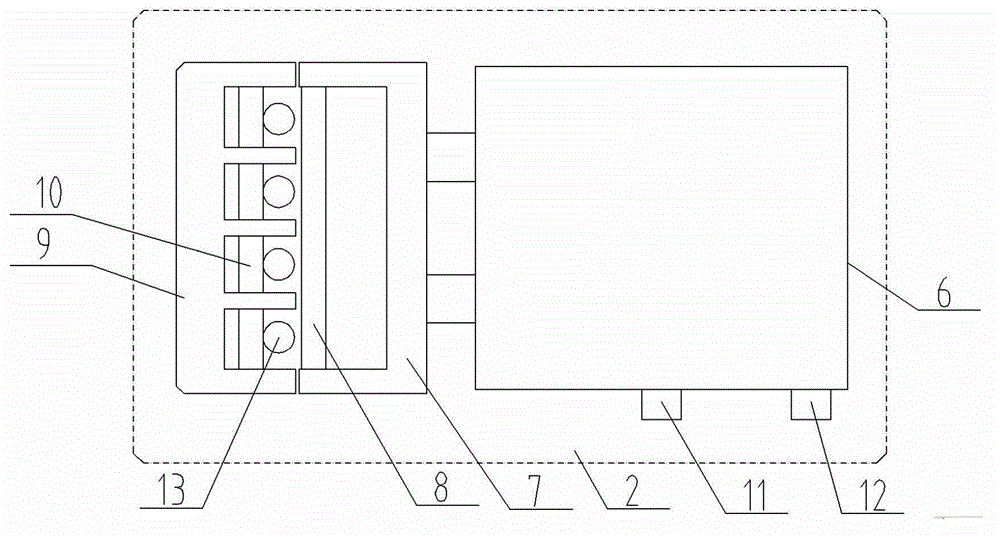

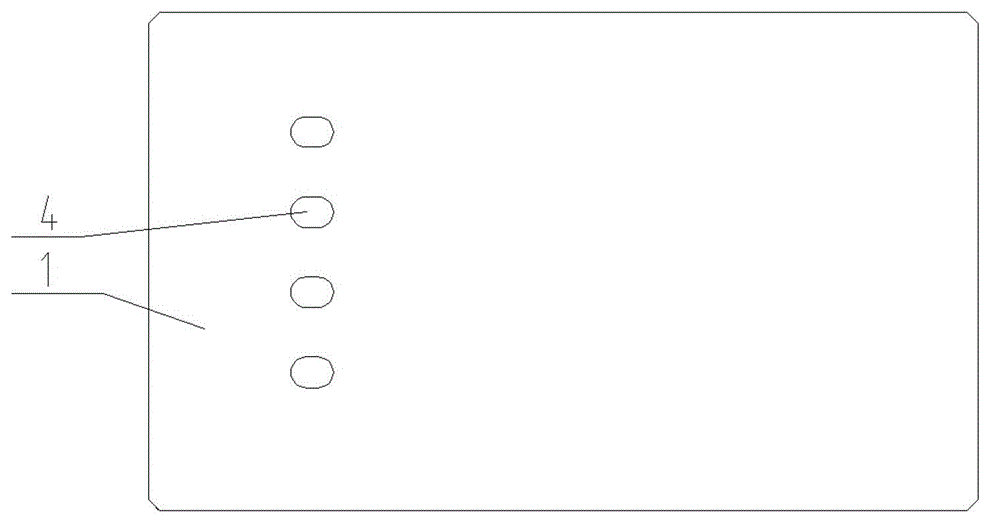

[0021] A pneumatic liquid hose valve such as figure 1 As shown, the pneumatic liquid hose valve includes an upper fixed plate 1, a lower fixed plate 2 and a pinch valve 3 between the upper fixed plate 1 and the lower fixed plate 2, and a hose is inserted into the upper fixed plate 1 Holes 4, hose extension holes 5 on the lower fixed plate 2, one side of the pinch valve 3 includes a cylinder 6, a movable push block 7 connected to the cylinder 6 and a push block connected to the push block 7 The other side of the pinch valve 3 includes a fixed block 9 and a second pinch shaft 10 connected to the block 9 .

[0022] In the original state, there is a space between one side of the pinch valve 3 and the other side, which is greater than the inner diameter of the flexible pipe 13, such as figure 2 As shown, the cylinder 6 us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com