Clamping and positioning process for arc-shaped stepped mirror part

A part and mirror technology, which is applied in the field of clamping and positioning process of arc stepped mirror parts, can solve problems such as inability to process, and achieve the effect of improving processing efficiency, ensuring the quality of appearance and surface, and protecting the surface of parts

Inactive Publication Date: 2020-12-22

SHENYANG FORTUNE PRECISION EQUIP CO LTD

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

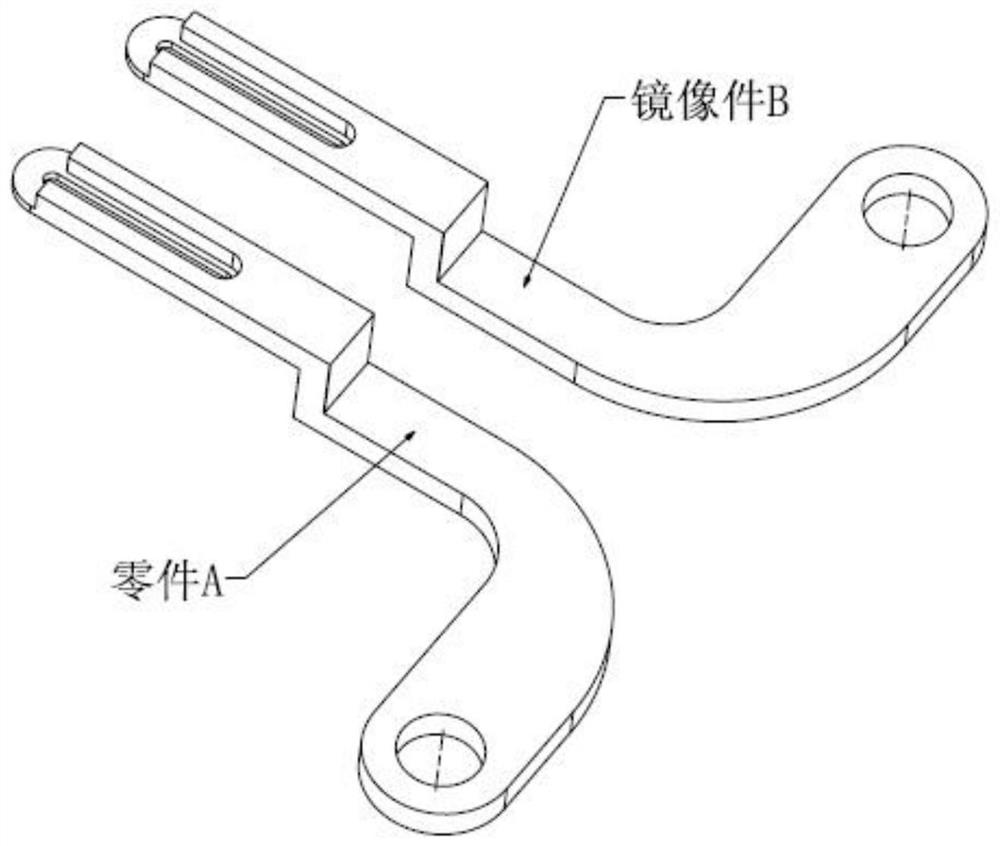

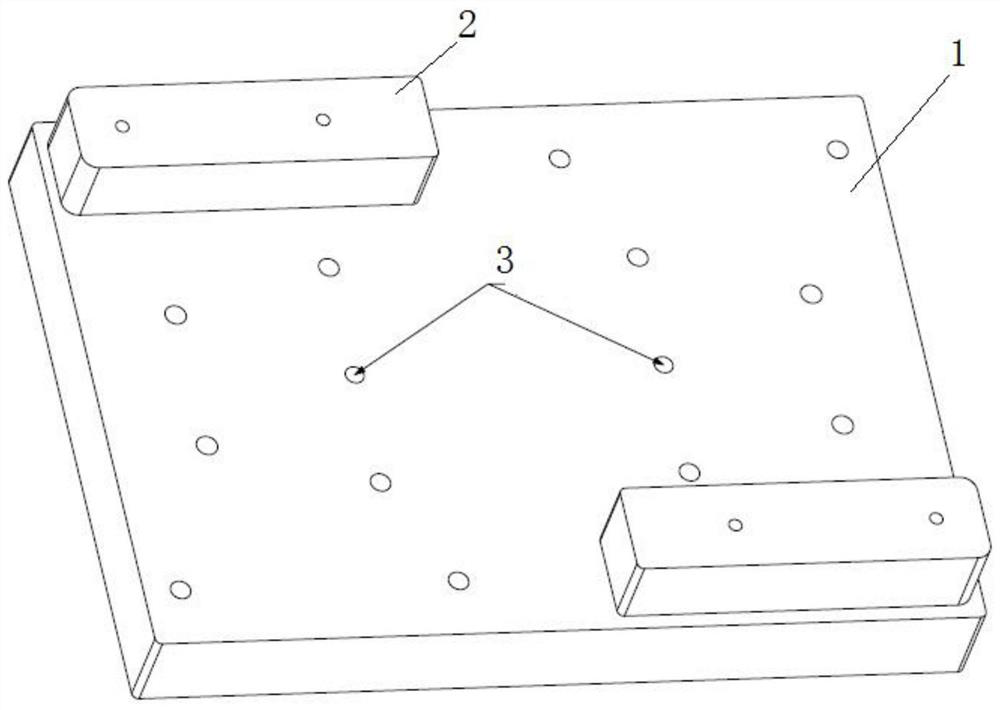

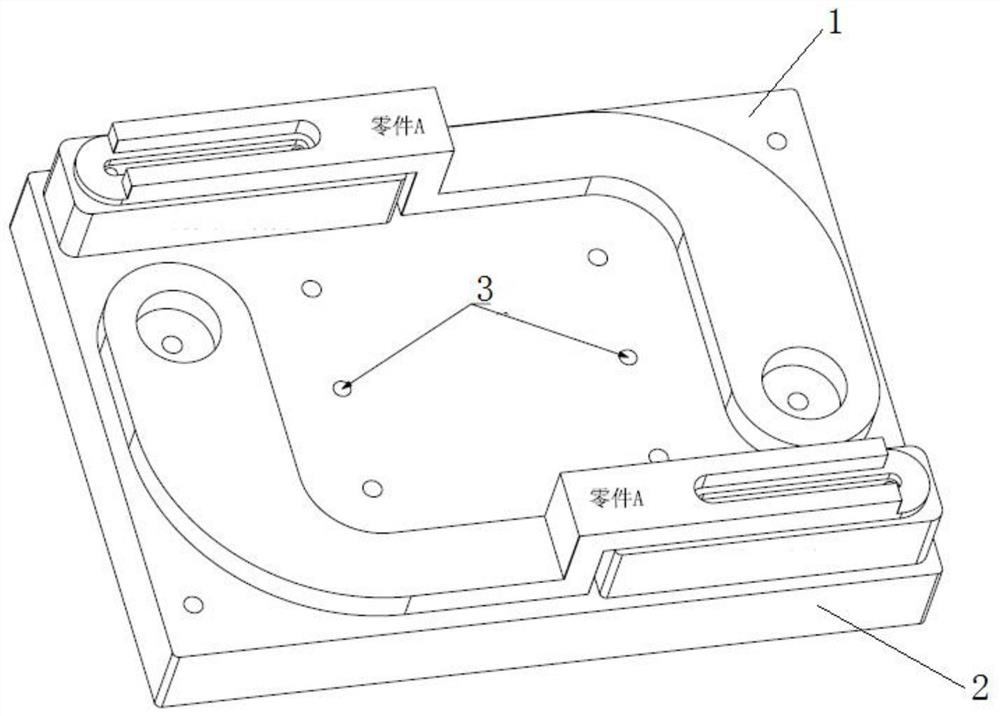

[0005] A clamping and positioning process for arc-shaped ladder mirror parts, using the detachable tooling block of the tooling, adjusting the position of the tooling block, realizing separately processing part A and its mirror image part B, and a set of combined tooling for processing two parts; using the tooling The tooling block and the step surface of the part are supported, and the screw is used to clamp the part to solve the problem that the step surface of the part is suspended and cannot be processed; the positioning hole of the tooling and the positioning hole at the residual material of the part are used for positioning to realize one-time alignment and repeated positioning processing, improving the alignment time of the parts; when the parts are processed and its mirror image B is processed, the tooling base does not move, and only the position of the detachable tooling block needs to be adjusted, and the parts can be processed without re-aligning the parts, saving the need for replacement parts. Positive time and tool setting time; tooling base and detachable tooling block are all processed by nylon, which is conducive to protecting the surface of the workpiece and is not easy to cause scratches on the workpiece

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0021] Using the tooling, the part A and the tooling are positioned through the positioning holes, and the two parts of the part A sink and the removable block of the tooling are firmly attached and locked.

[0022] When processing the mirror image B, adjust the position of the detachable tooling block and process the mirror image B.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a clamping and positioning process for an arc-shaped stepped mirror part, and belongs to the field of cold machining. According to the process, by using detachable tool blocksof a tool and adjusting the position of the tool blocks, respective machining of a part A and a mirror part B of the part A is realized, and machining of the two parts is realized by a set of combined tool. The tool blocks of the tool are used for supporting step surfaces of the parts, the parts are clamped through cooperation of screws, and the problem that the step surfaces of the parts are suspended and cannot be machined is solved. The parts are positioned through positioning holes, the detachable tool blocks are used for supporting the step faces of the parts, the parts are limited and locked, one-time clamping and repeated positioning machining can be achieved, the two parts can be clamped and machined at the same time, the machining efficiency is greatly improved, and meanwhile thestability of part quality is guaranteed.

Description

technical field [0001] The invention belongs to the field of cold processing industry, in particular to a clamping and positioning process for curved stepped mirror parts. It is suitable for processing arc-shaped stepped parts and their mirror parts. Background technique [0002] In the field of semiconductor processing, there are many arc-shaped stepped mirror parts. The shape of the part itself belongs to the thin-walled irregular part. If the vise is used for clamping and processing, due to the structural characteristics of the part, the vise can only process one side of the part. The other side cannot be processed with a vise, and there is no suitable clamping tool. In order to solve this problem, it is necessary to develop a clamping and positioning process for arc-shaped stepped mirror parts. Contents of the invention [0003] In view of the above-mentioned problems, the object of the present invention is the processing technology of arc-shaped stepped mirror parts,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23Q3/06B25B11/00

CPCB23Q3/062B25B11/00

Inventor 娄微郑广文

Owner SHENYANG FORTUNE PRECISION EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com