A Lubrication Mechanism Based on Variable Volume

A technology of variable volume mechanism and lubricating mechanism, which is applied in gear lubrication/cooling, manipulators, manufacturing tools, etc., and can solve problems such as robot penetration of grease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

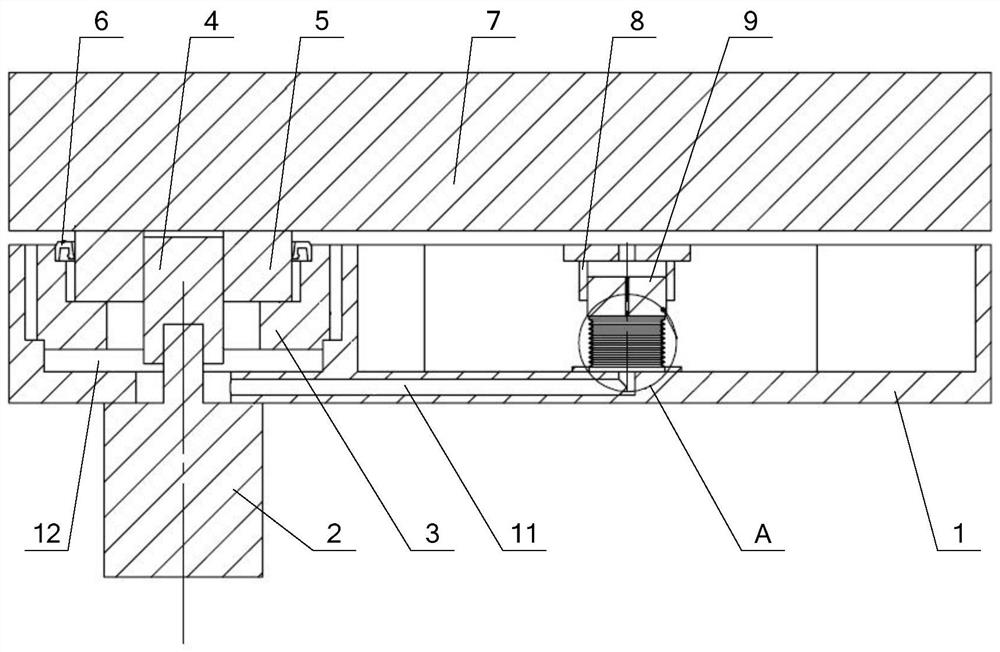

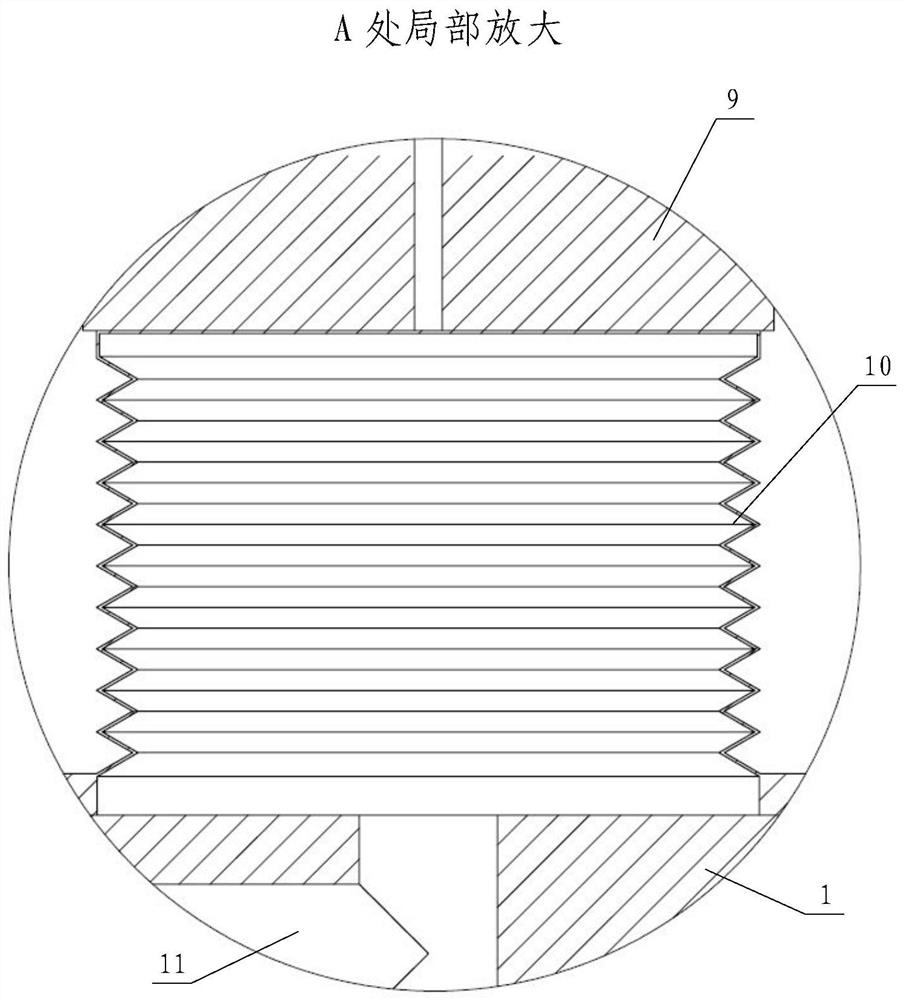

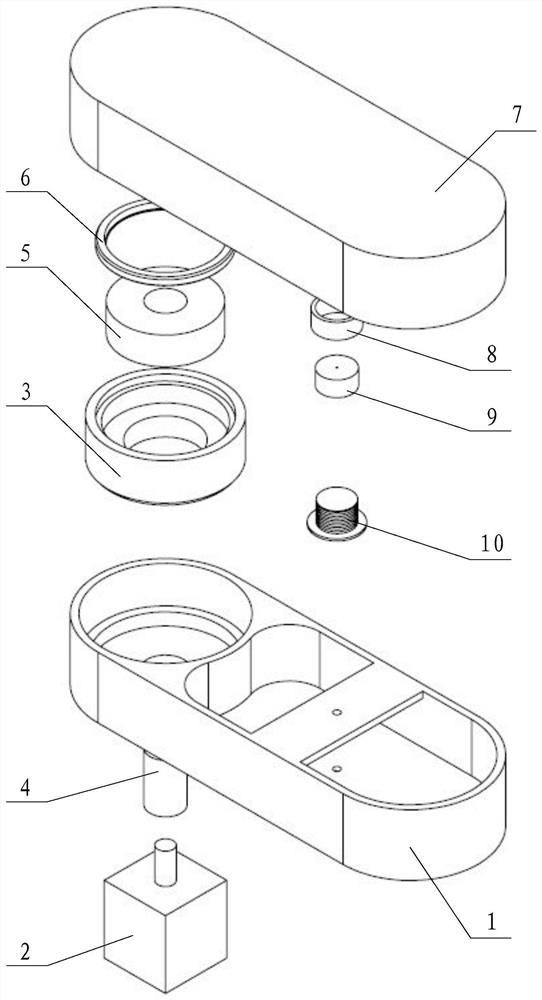

[0020] Such as Figure 1~3 As shown, the present invention includes a boom 1, a small arm 7, a motor 2, and a reducer casing 3, a reducer input gear shaft 4, a reducer output shaft 5 and an elastic variable volume mechanism 10 respectively housed in the boom 1. The boom 1 is relatively fixed, the motor 2 is statically sealed and fixedly connected to the boom 1, the output end penetrates into the boom 1, and is connected to one end of the reducer output shaft 5 through the reducer input gear shaft 4, and the reducer casing 3 One end is statically sealed and fixedly connected in the boom 1, and the other end is sealed and rotated with the reducer output shaft 5 through the rotating dynamic seal 6. The other end of the reducer casing 3 is connected with the reducer input gear shaft 4 and the reducer output shaft 5. And the rotary dynamic seal 6 forms the transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com