Coil component

一种线圈部件、芯部的技术,应用在变压器/电感的零部件、电气元件、电感器等方向,能够解决磁阻增加、粘合强度降低、不易兼顾粘合强度的确保和电感的确保等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

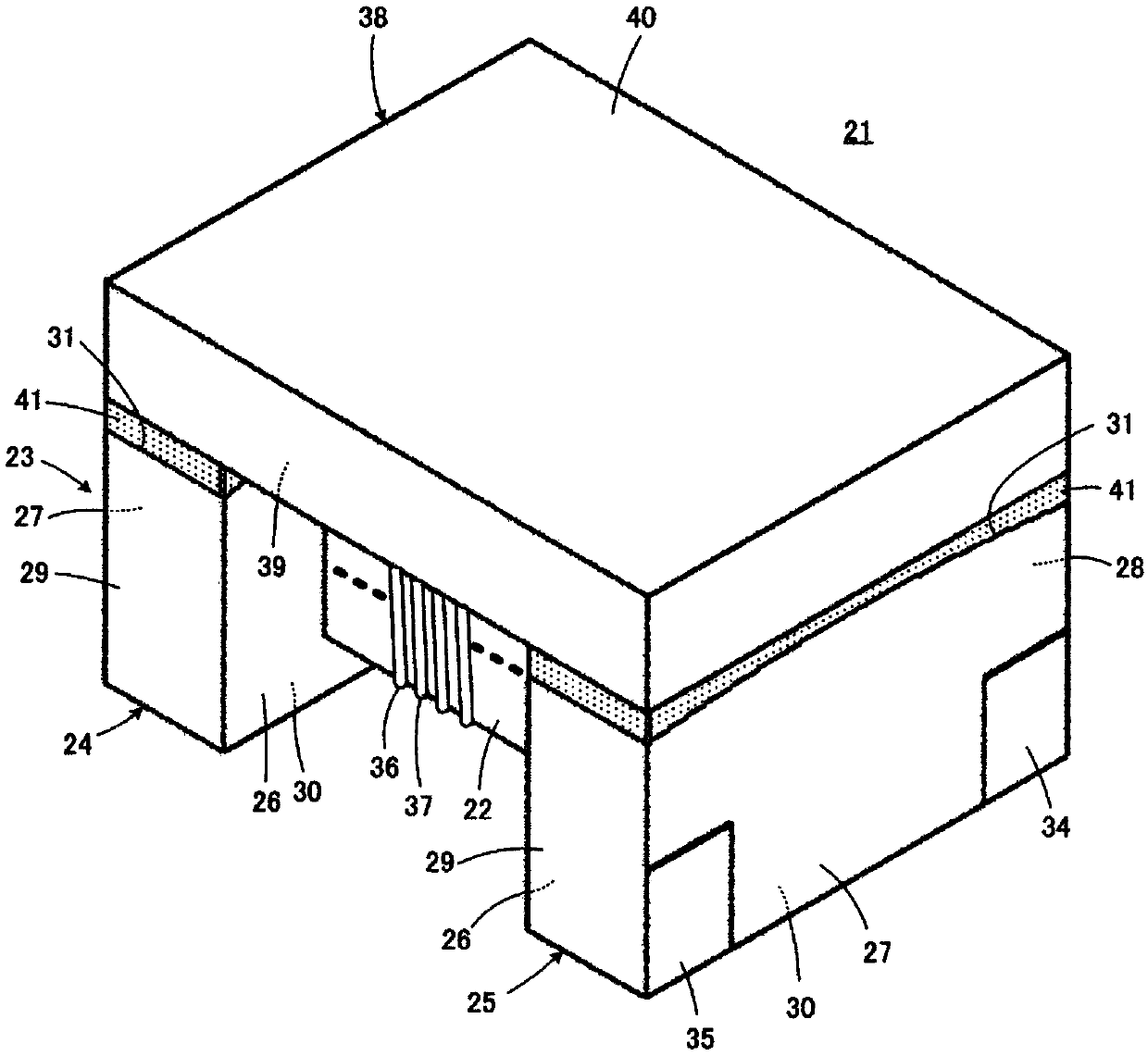

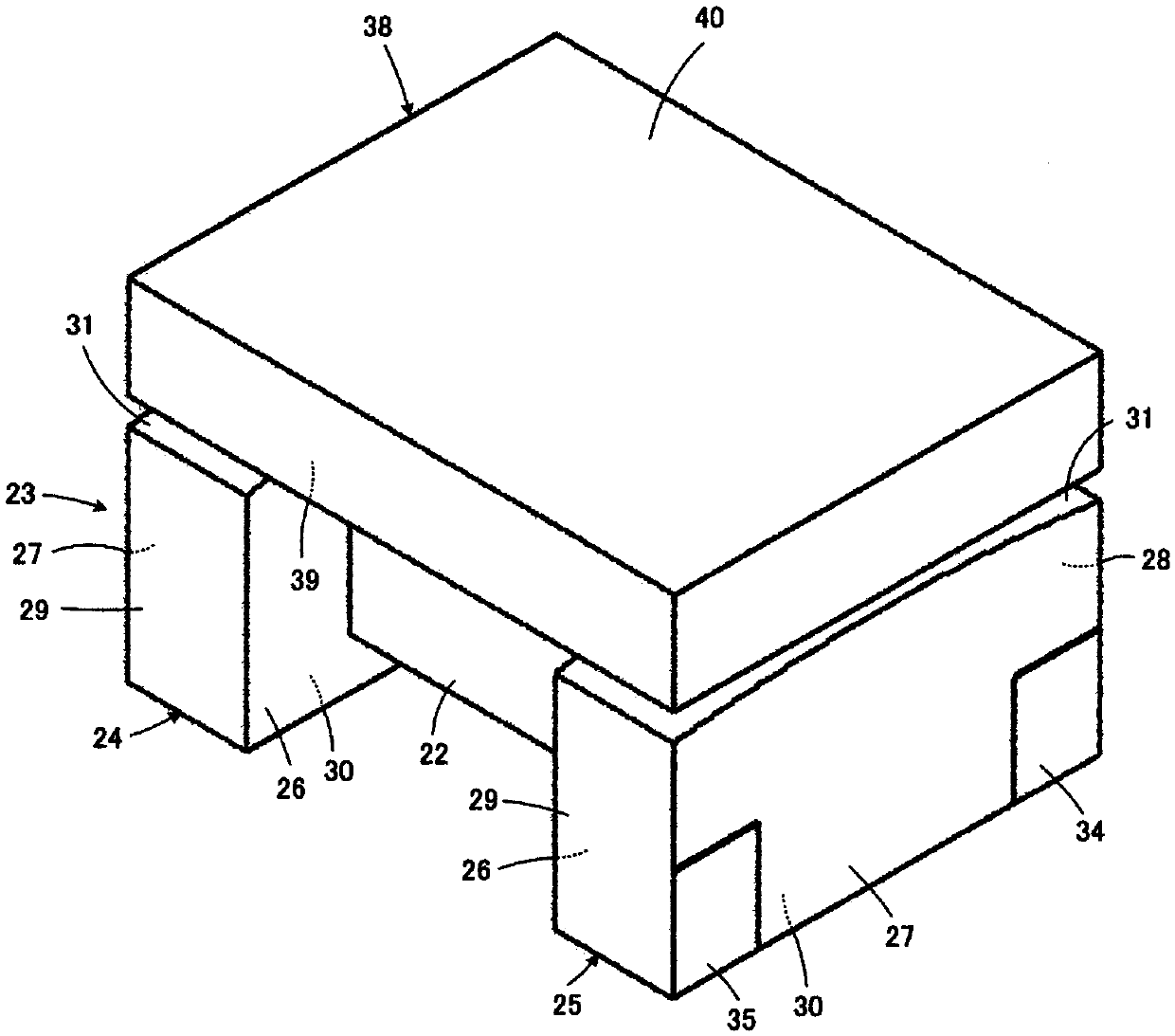

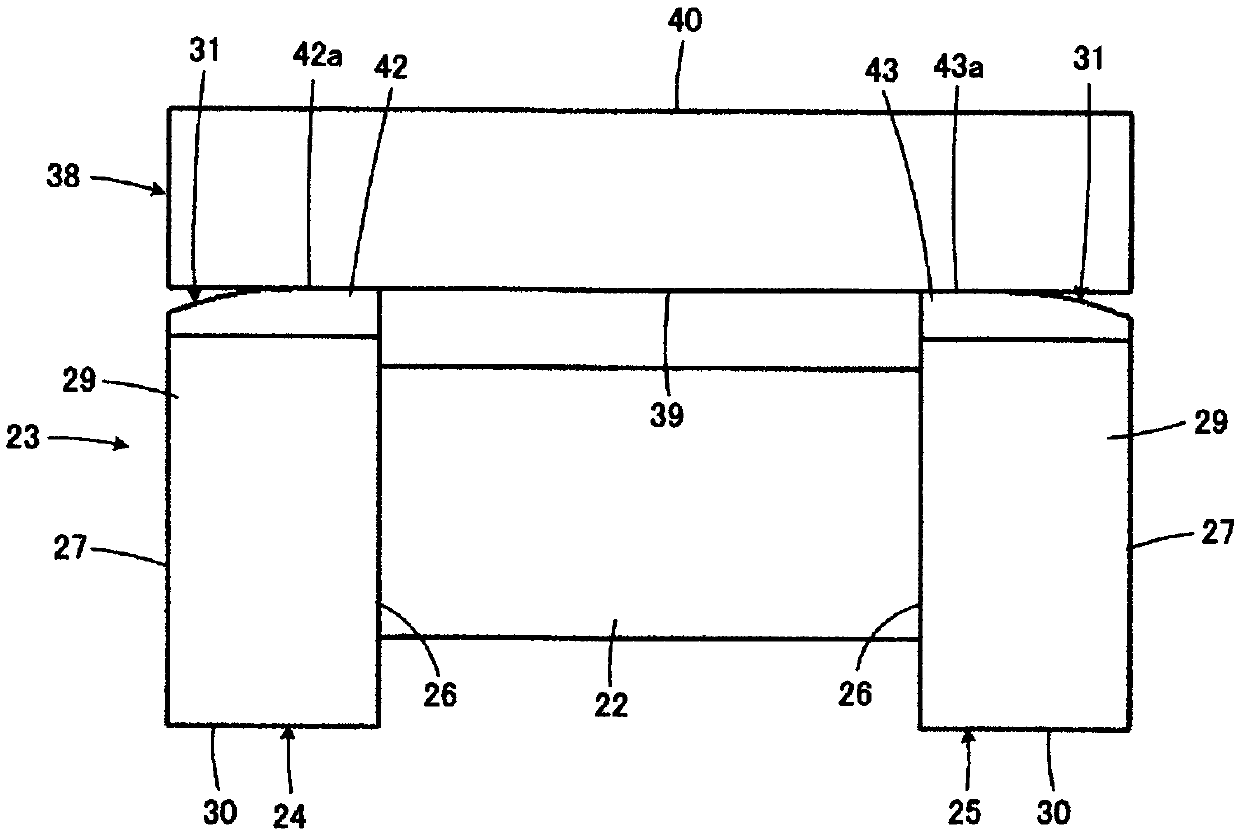

[0044] refer to Figure 1 ~ Figure 4 , the coil component 21 according to the first embodiment of the present invention will be described. The illustrated coil component 21 constitutes, for example, a common mode choke coil.

[0045] The coil component 21 includes a drum-shaped core 23 having a winding core 22 . The drum-shaped core portion 23 is provided with a first flange portion 24 and a second flange portion 25 respectively provided at first and second end portions opposite to each other in the axial direction of the winding core portion 22 . The drum-shaped core 23 is made of a magnetic material, more specifically, a magnetic body such as NiZn ferrite, a resin containing a metal amorphous material or magnetic powder, or the like. The winding core portion 22 included in the drum-shaped core portion 23 has, for example, a quadrangular prism shape having a substantially quadrangular cross-sectional shape.

[0046] The first flange portion 24 and the second flange portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com