Composite cord and tire using same

A composite cord and cord technology, applied in the field of composite cords, can solve problems such as poor adhesion of aramid fibers, and achieve the effects of reducing handling stability and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

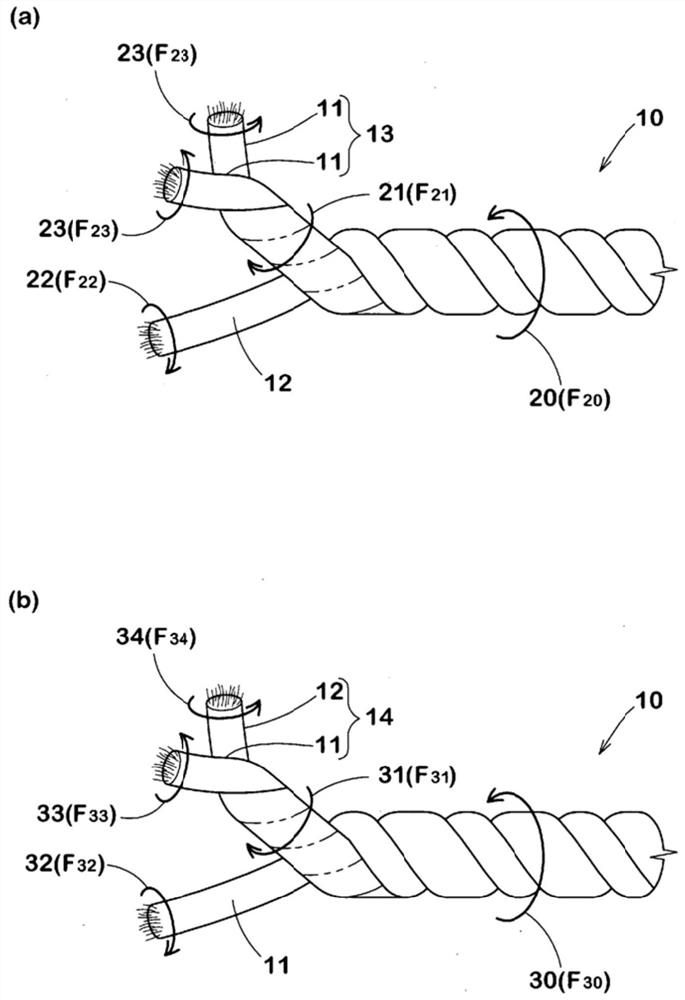

Method used

Image

Examples

Embodiment

[0077] In order to confirm the effects of the present invention, composite cords were trial-produced with the specifications shown in Table 1, and a pneumatic tire (265 / 35R18) using the trial-produced composite cords as belt cords was formed. Then, the cord strength and rubber pullout resistance of each composite cord were measured. In addition, steering stability and high-speed durability were measured for each pneumatic tire. The specifications of the pneumatic tires are substantially the same except for the belt cord (composite cord). Embodiment 2 and Embodiment 3 are only different in the number of twists.

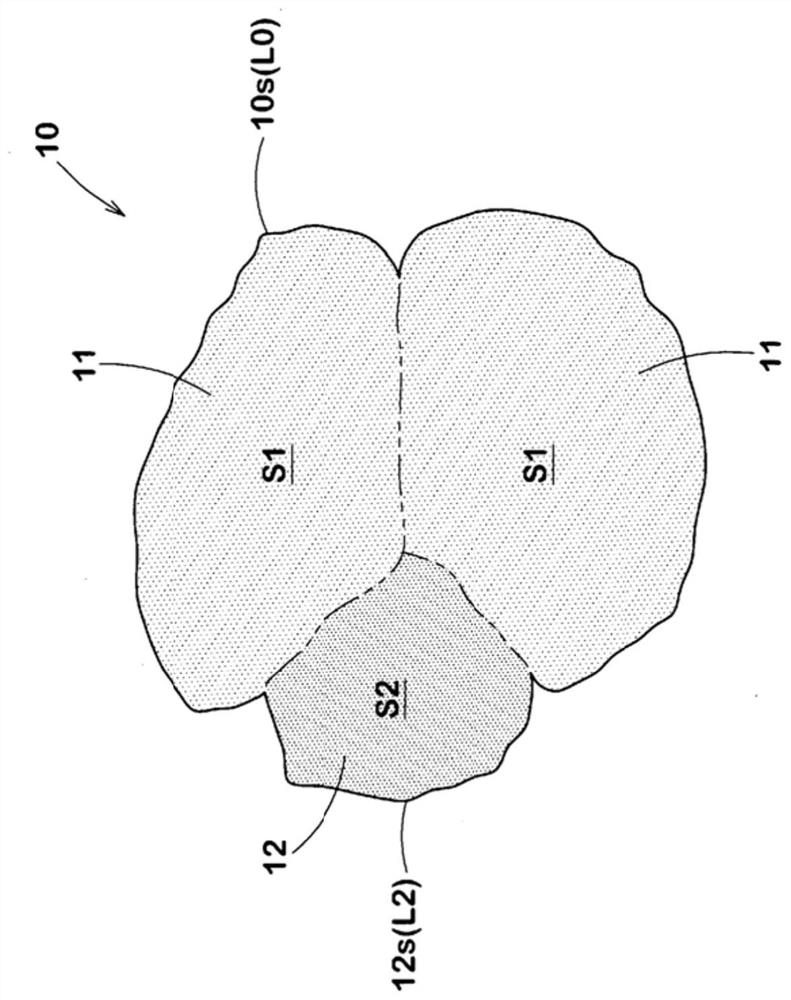

[0078] L0 (the length of the outer circumference of the cord along the exposed surface of the composite cord) and L2 (the length of the outer circumference of the cord along the exposed surface of the second strand) are the cross-sections of the composite cord with FIB, and then used The cross-section of the composite cord acquired by SEM is obtained through image an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com