Battery

A battery and battery cell technology, applied in battery pack parts, battery boxes/jackets, circuits, etc., can solve the problems of not being a commodity, detachment, economic loss, etc., to prevent detachment, ensure the bonding area, and improve the yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

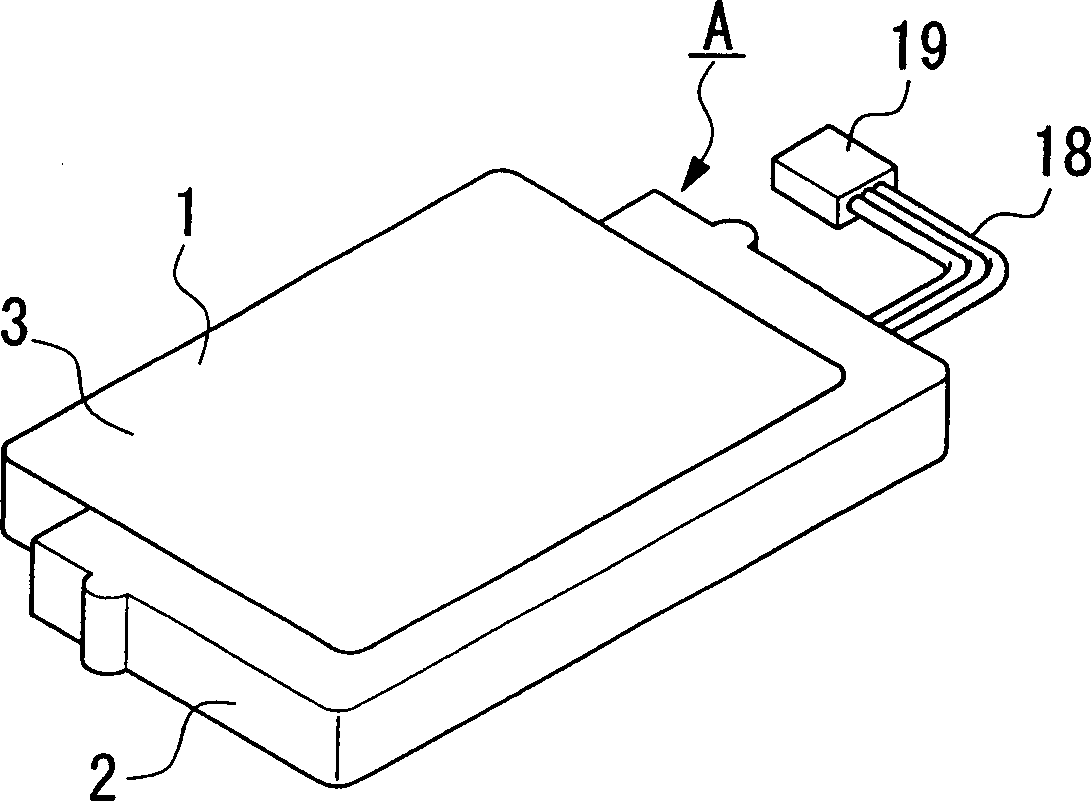

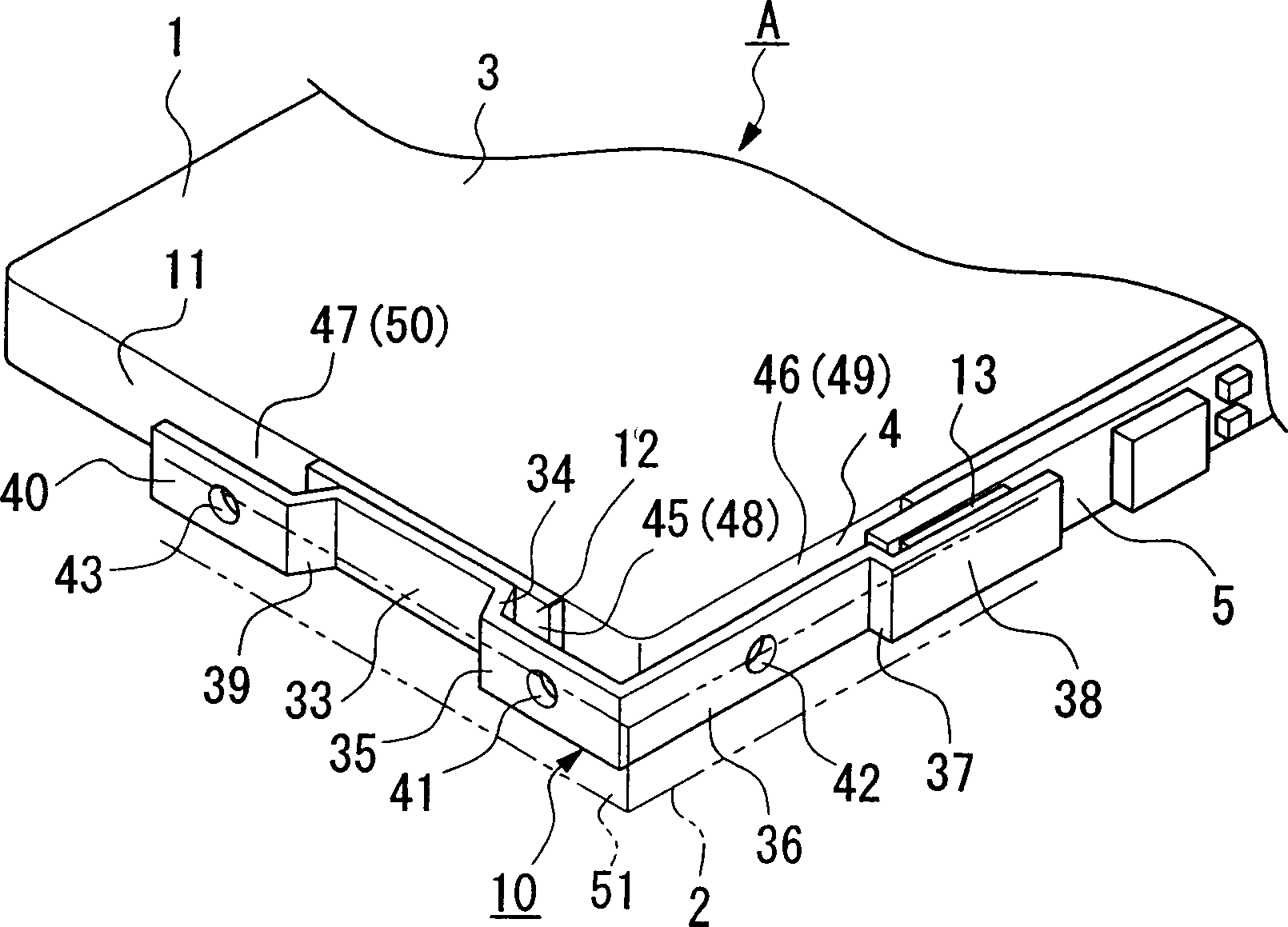

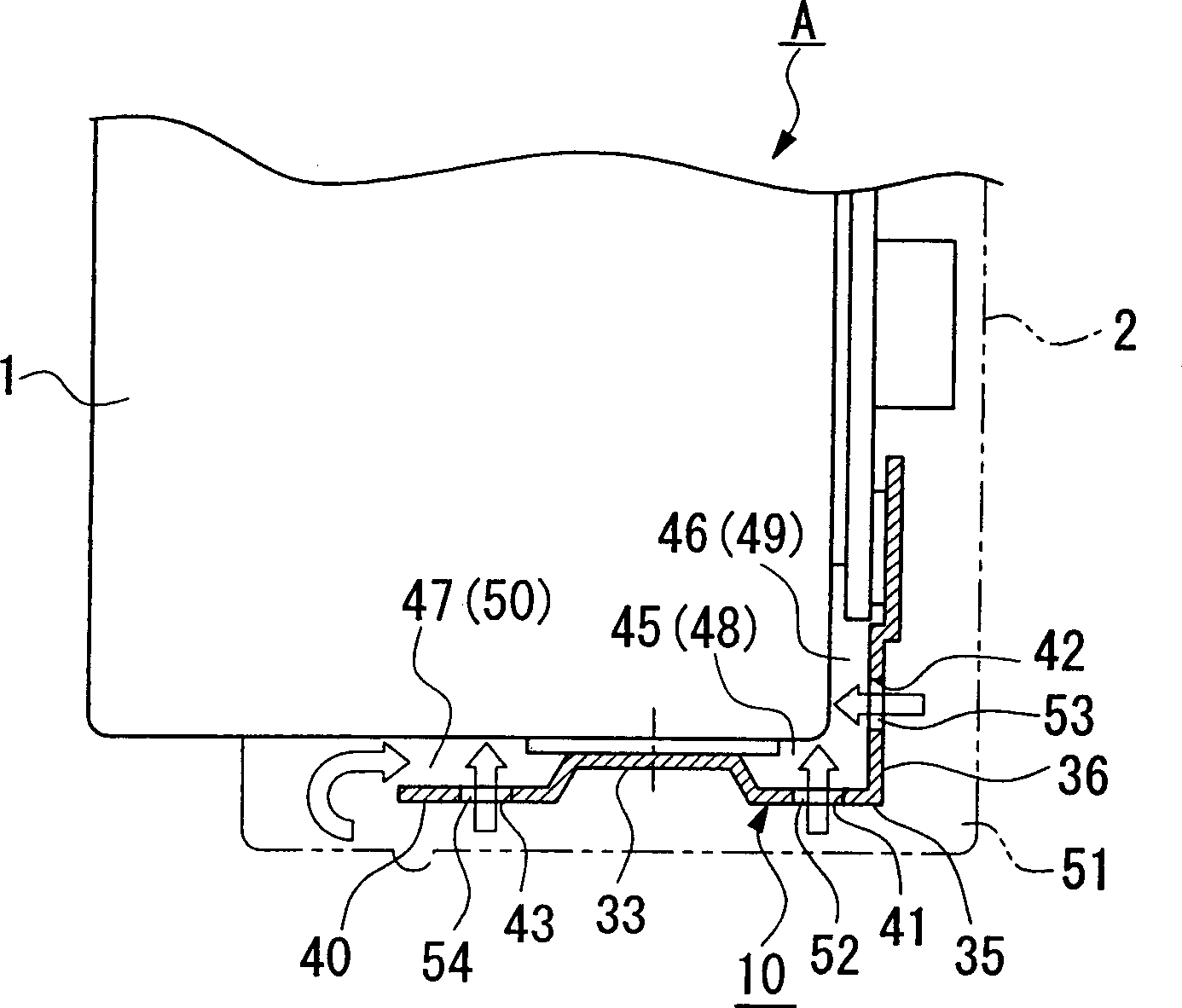

[0029] Hereinafter, an embodiment of the present invention will be described with reference to the accompanying drawings. Figure 1 to Figure 3 Indicates that the mobile terminal battery of the present invention is applied, and the mobile terminal battery A (battery) shown in the figure includes a battery unit 1, a circuit board 5 assembled in the battery unit 1, and the battery unit 1 and the circuit board 5. The electrode terminals 10 for circuit connection are formed, and the circuit board 5 and the electrode terminals 10 are integrated with the battery cell 1 through the molding part 2. This basic structure is related to the Figure 4 to Figure 6 The cells shown are of the same construction.

[0030] In addition, in Figure 1 to Figure 3 , for which and Figure 4 to Figure 6 The parts shown with the same configuration use the same symbols, and their descriptions are omitted. Below, only for Figure 4 to Figure 6 different parts are explained.

[0031] The battery A for m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com